6

English

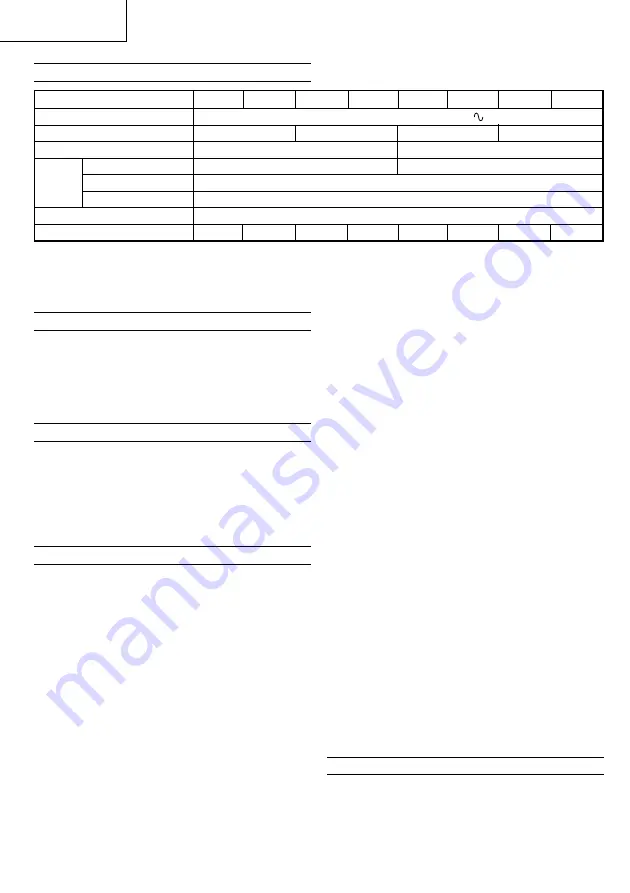

SPECIFICATIONS

*1 Be sure to check the nameplate on product as it is subject to change by areas.

*2 Weight: Only main body

*3 The starting current limiter produces the starting current to such an extent that a fuse (16A, slow-blow)

is not tripped.

STANDARD ACCESSORIES

(1) Wrench ........................................................................ 1

(2) Side handle ................................................................ 1

Depressed center wheels are not provided as standard

accessories.

Standard accessories are subject to change without

notice.

APPLICATIONS

䡬

Removal of casting fin and finishing of various types

of steel, bronze and aluminum materials and castings.

䡬

Grinding of welded sections or sections cut by

means of a cutting torch.

䡬

Grinding of synthetic resins, slate, brick, marble, etc.

䡬

Cutting of synthetic concrete, stone, brick, marble

and similar materials.

PRIOR TO OPERATION

1. Power source

Ensure that the power source to be utilized conforms

to the power requirements specified on the product

nameplate.

2. Power switch

Ensure that the power switch is in the OFF position.

If the plug is connected to a receptacle while the

power switch is in the ON position, the power tool

will start operating immediately, which could cause

a serious accident.

3. Extension cord

When the work area is removed from the power

source, use an extension cord of sufficient thickness

and rated capacity. The extension cord should be

kept as short as practicable.

4. Fitting and adjusting the wheel guard

The wheel guard is a protective device to prevent

injury should the depressed center wheel shatter

during operation. Ensure that the guard is properly

fitted and fastened before commencing grinding

operation.

[Installing and adjusting the wheel guard]

䡬

Open the lever and insert the locating pin of wheel

guard, bringing it into line with the across flats of

packing ground.

䡬

Then, turn the wheel guard to a desired position

(for use).

䡬

Close the lever and fix it. If and when required,

carry out adjustments by tightening or loosening

the screw.

䡬

If the lever does not move smoothly, apply some

lubricating oil to the sliding section between the set

piece and the lever.

䡬

Fasten the wheel guard at the position where the

across flats of the wheel guard positioning pin and

packing ground are aligned (the position where the

wheel guard is inserted), but do not use it.

5.

Ensure that the depressed center wheel to be utilized

is the correct type and free of cracks or surface

defects. Also ensure that the depressed center wheel

is properly mounted and the wheel nut is securely

tightened, refer to the section on “Depressed Center

Wheel Assembly”.

6. Conducting a trial run

Ensure that the abrasive products is correctly

mounted and tightened before use and run the tool

at no-load for 30 seconds in a safe position, stop

immediately if there is considerable vibration or if

other defects are detected.

If this condition occurs, check the machine to

determine the cause.

7. Confirm the spindle lock mechanism

Confirm that the spindle lock is disengaged by

pushing push button two or three times before

switching the power tool on (See

Fig. 1

).

8. Fixing the side handle

Screw the side handle into the gear cover.

PRACTICAL GRINDER APPLICATION

1. Pressure

To prolong the life of the machine and ensure a

first class finish, it is important that the machine

should not be overloaded by applying too much

pressure. In most applications, the weight of the

Model

G18SE3

G18UA2

G18SG2

G18UB2 G23SC3

G23UA2 G23SE2

G23UB2

Voltage (by areas)*

1

(110V, 220V, 230V, 240V)

Input*

1

2300 W

2500 W

2300 W

2500 W

No-load speed

8500 min

-1

(/min)

6600 min

-1

(/min)

Outer dia.

180 mm

230 mm

Wheel

Inner dia.

22 mm

Peripheral speed

80 m/s

Weight*

2

5.0 kg

Starting current limiter*

3

No

Yes

No

Yes

No

Yes

No

Yes

Summary of Contents for G 18SG2

Page 11: ...48 1 2 3 4 5 ...