-10-

Fig. 6

Solderless connection

Tightening Torque

Adhesive Agent

Insulation Tests

No-Load Current Value

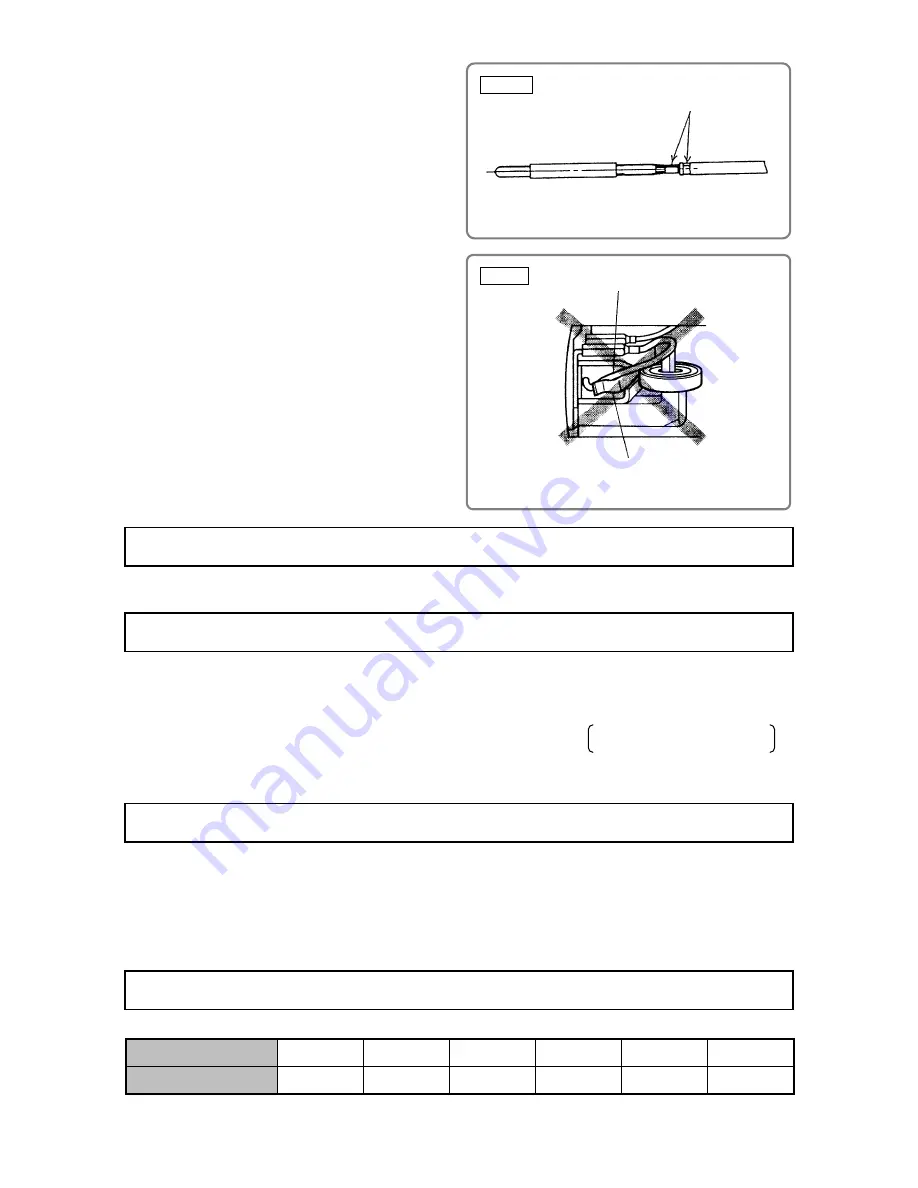

(3) When connecting the Earth Terminal

[37]

to

the internal wire (middle wire among three) of

the Noise Suppressor

[38]

, strip off about 6

mm of the insulation sheath on the internal

wire, and then press-connect it together with

the Earth Terminal

[37]

with a clamping tool

available on the market.

(4) Confirm that the spring end does not hold the

pigtail when mounting the carbon brush. Do

not catch the pigtail in the tail cover when

mounting the tail cover.

•

Hex. Socket Set Screw M4 x 4

[16]

-------------------------- TB1406 (Synthetic rubber base)

•

Tapping Screw D4

[19][36][41]

------------------------------- 2.0 ± 0.5 N

•

m (20 ± 5 kgf

•

cm, 1.5 ± 0.4 ft-lbs)

•

Seal Lock Screw (W/Sp. Washer) M4 x 10

[11]

----------- 1.8 ± 0.5 N

•

m (18 ± 4 kgf

•

cm, 1.3 ± 0.3 ft-lbs)

•

Tapping Screw (W/Sp. Washer) D5 x 30

[6]

--------------- 2.9 ± 0.5 N

•

m (30 ± 5 kgf

•

cm, 2.2 ± 0.4 ft-lbs)

•

Hex. Socket Set Screw M4 x 4

[16]

--------------------------- 0.5 N

•

m 5

kgf

•

cm,

0.4 ft-lbs

0

0

0

•

Bearing Lid (B)

[2]

------------------------------------------------ 6.9 ± 0.5 N

•

m (70 ± 5 kgf

•

cm, 5.0 ± 0.4 ft-lbs)

Upon the completion of disassembly and repair, measure the insulation resistance and conduct a dielectric

strength test.

Insulation resistance: 10 M

Ω

or more with DC 500 V megohm tester

Dielectric strength test: AC 4,400 V for 3 seconds, with no abnormalities ----------- 220 to 240 V products

AC 3,000 V for 3 seconds, with no abnormalities ----------- 110 to 127 V products

After no-load operation for 30 minutes, the no-load current value should be as follows:

Voltage (V)

110

120

127

220

230

240

Current (A) max.

4.9

4.7

4.0

2.5

2.4

2.3

Pigtail

Spring end

Fig. 7

0.5 +

5 +

0.4 +