4

English

MOUNTING AND OPERATION

Action

Figure

Page

Inserting SDS-max tools

1

14

Removing SDS-max tools

2

14

Deciding working position of tool

3

14

Adujsting the side handle position

4

14

Switch operation

5

14

Locking-on the On / O

ff

switch

6

15

Releasing the On / O

ff

switch

7

15

About the power lamp

8

15

Speed change

9

15

How to use the demolition hammer*

10

16

Selecting accessories

―

17

* Operate this Demolition Hammer by utilizing its empty

weight. The performance will not be better even if it is

pressed or thrust forcibly against the work surface.

Hold this Demolition Hammer with a force just su

ffi

cient

to counteract the reaction.

CAUTION

After long time of use, the housing becomes hot.

Therefore, be careful not to burn your hands.

Warming up (Fig. 11)

The grease lubrication system in this unit may require

warming up in cold regions.

Position the end of the bit so makes contact with the

concrete, turn on the switch and perform the warming

up operation. Make sure that a hitting sound is produced

and then use the unit.

ABOUT THE PROTECTION

FUNCTION

This tool has a built-in protection circuit for preventing

damage to the unit in the event of an abnormality. Depending

on the nature of the abnormality, the display lamp will

fl

ash

as shown in

Table 1

and the unit will cease to operate. In

such cases, verify the problem indicated by the

fl

ashing and

take whatever steps are necessary to correct the problem.

NOTE

Repair may be required if the display lamp continues to

fl

ash after taking all necessary steps to correct the problem.

If the problem persists, please arrange for repairs.

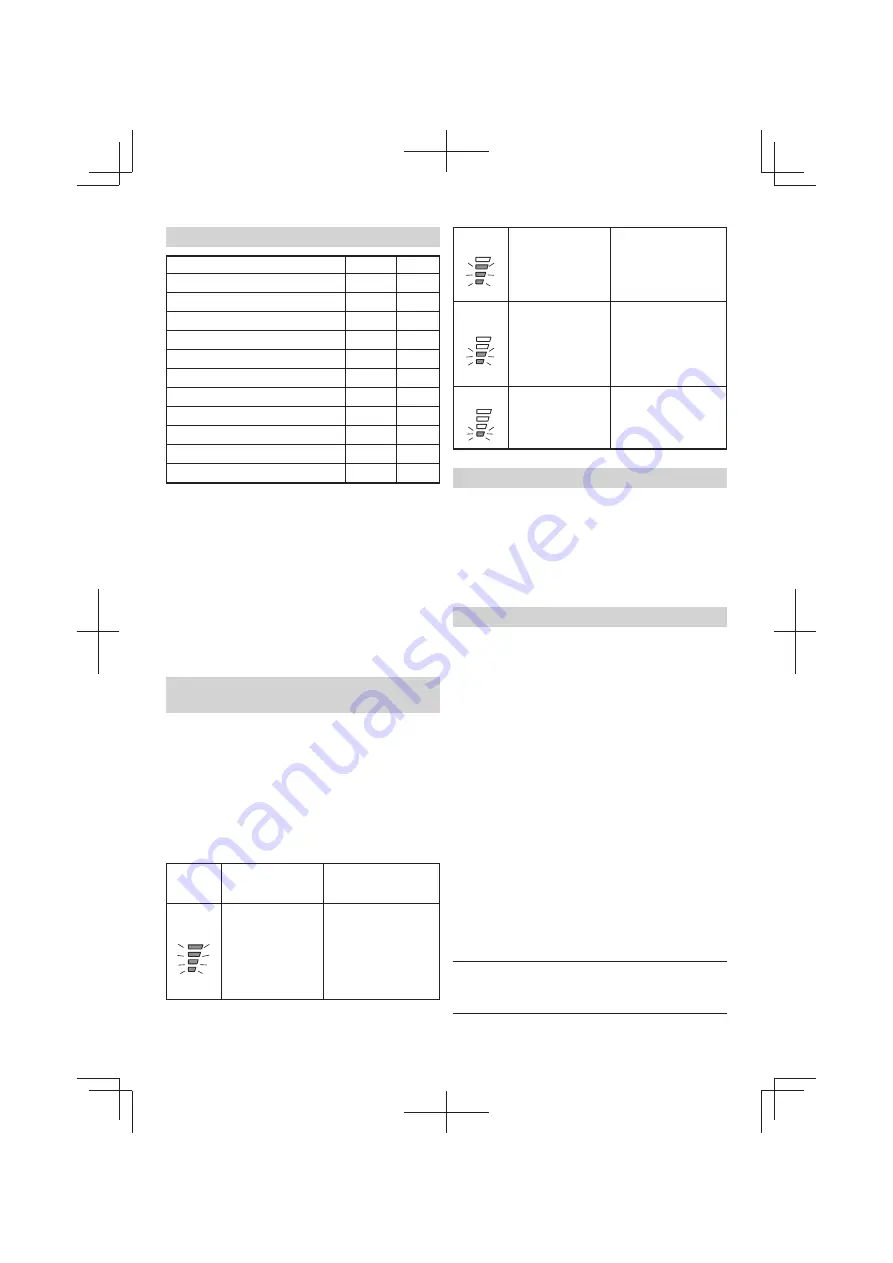

Table 1

Display

lamp

fl

ashing

Cause

Solution

Flash

Internal temperature

has risen beyond

the unit’s speci

fi

ed

temperature.

(Temperature

increase protection

function)

Turn o

ff

the unit

and allow it to cool

down for about 15 to

30 minutes.

When the temperature

goes down, press the

impact rate selector

switch to recover.

Flash

Excessive pressure

applied to the tool

has resulted in an

overload.

(Overload

protection function)

Press the impact rate

selector switch to

recover. Try to avoid

tasks that will apply

excess pressure to

the unit.

Flash

Tool is connected

to a power source

whose voltage is

either too high or

too low.

(Circuit protection

function)

Connect the unit to a

power supply matching

the input voltage

speci

fi

ed on the

nameplate. Press the

impact rate selector

switch to recover.

Flash

Sensor signal read

error.

(Control monitoring

function)

Press the impact rate

selector switch to

recover. Repair may

be required if this error

continuously occurs.

GREASE REPLACEMENT

This Demolition Hammer is of full air-tight construction to

protect against dust and to prevent lubricant leakage.

Therefore, this Demolition Hammer can be used without

lubrication for long periods. Replace the grease as described

below.

Grease Replacement Period

After purchase, replace grease after every 6 months of

usage. Ask for grease replacement at the nearest authorized

Service Center.

MAINTENANCE AND INSPECTION

CAUTION

Be sure to switch OFF and disconnect the attachment

plug from the receptacle to avoid a serious accident.

1. Inspecting accessories

Since use of a dull accessory, such as a bull point, a

cutter, etc. will degrade e

ffi

ciency and cause possible

motor malfunction, sharpen or replace with a new one as

soon as abrasion is noted.

2. Inspecting the mounting screws

Regularly inspect all mounting screws and ensure that

they are properly tightened. Should any of the screws be

loose, retighten them immediately. Failure to do so could

result in serious hazard.

3. Maintenance of the motor

The motor unit winding is the very “heart” of the power

tool. Exercise due care to ensure the winding does not

become damaged and/or wet with oil or water.

4. Replacing supply cord

If the replacement of the supply cord is necessary, this

has to be done by the manufacturer of this agent in order

to avoid a safety hazard.

CAUTION

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

NOTE

Due to HITACHI’s continuing program of research and

development, the speci

fi

cations herein are subject to

change without prior notice.

0000Book̲H45ME.indb 4

0000Book̲H45ME.indb 4

2016/06/10 9:24:44

2016/06/10 9:24:44

Summary of Contents for H 45ME

Page 16: ...16 10 11 0000Book H45ME indb 16 0000Book H45ME indb 16 2016 06 10 9 24 47 2016 06 10 9 24 47 ...

Page 18: ...18 0000Book H45ME indb 18 0000Book H45ME indb 18 2016 06 10 9 24 47 2016 06 10 9 24 47 ...

Page 19: ...19 0000Book H45ME indb 19 0000Book H45ME indb 19 2016 06 10 9 24 47 2016 06 10 9 24 47 ...