--- 15 ---

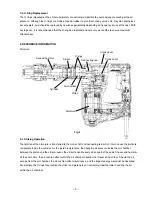

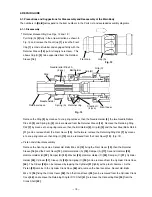

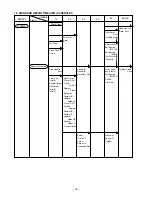

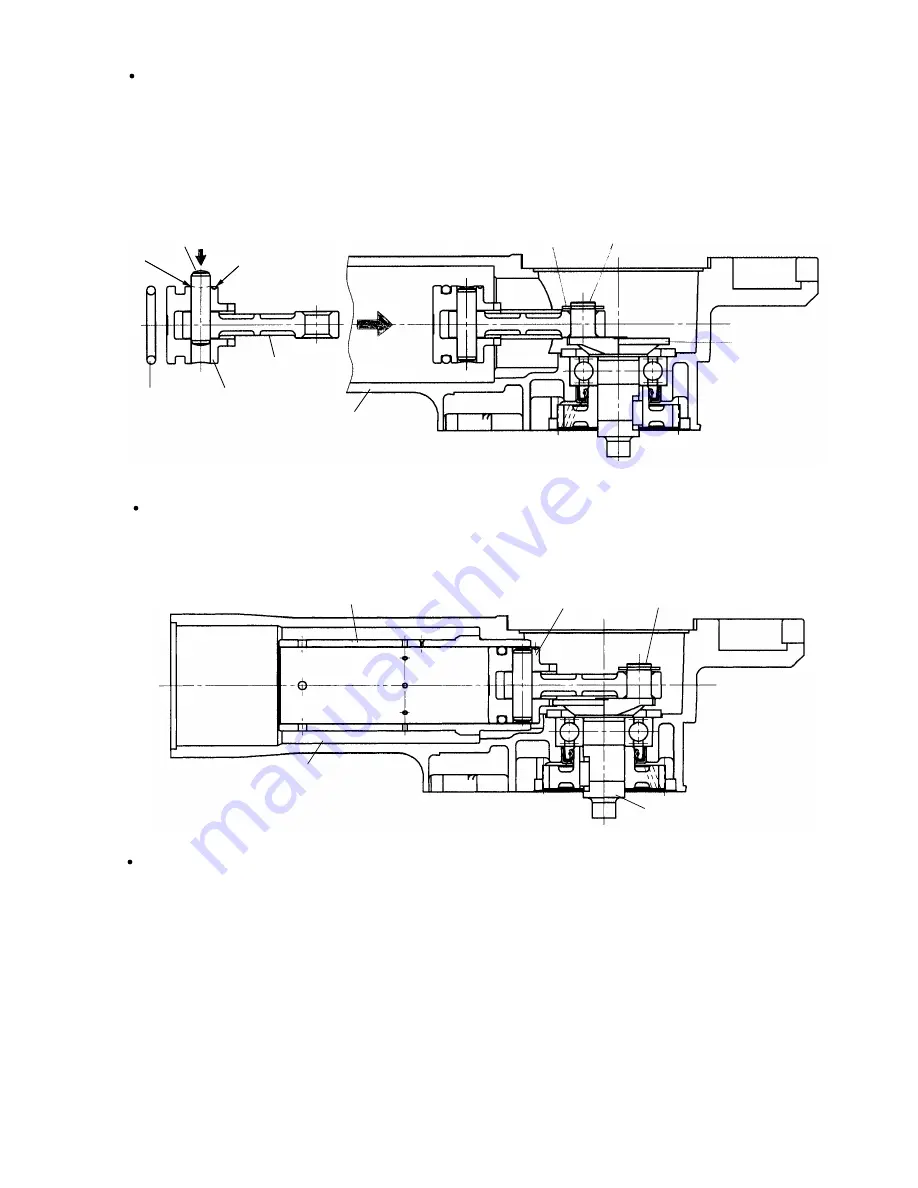

Insert the Piston Pin [32] into the D8 hole (marked) of the Piston [33] and the Connecting Rod [34] then press-

fit it. Be careful not to protrude the Piston Pin [32] from the outside diameter of the Piston [33]. Move the

crank pin of the Crank Shaft [42] to the bottom dead center and insert the piston ass'y into the Crank Shaft

[42] from the cylinder case of the Cylinder Crank Case [48]. Mount the Retaining Ring for D10 Shaft [41]

using a retaining ring puller.

Fig. 16

Crank shaft

Piston pin

D8 hole

Cylinder crank case

Retaining ring

Piston reassembly

Crank pin portion

Mark

Connecting rod

O-ring

Piston

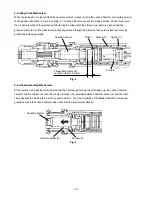

Cylinder reassembly

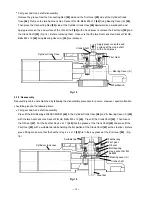

Move the crank pin of the Crank Shaft [42] then move the Piston [33] to the top dead center. Insert the

Cylinder [31] into the Cylinder Crank Case [48].

Cylinder

Fig. 17

Cylinder crank case

Crank pin portion

Piston

Crank shaft

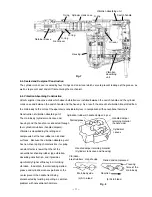

Lubrication

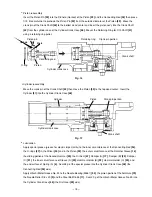

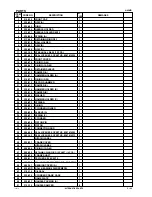

Apply special grease (grease for electric impact drills) to the inner circumference of the Connecting Rod [34],

the O-rings [27] in the Striker [26] and in the Piston [33], the outer circumference of the Retainer Sleeve [16],

the sliding portion of the Second Hammer [20], the Oil Seal [47], Damper (A) [17], Damper (B) [23], Damper

(C) [21], the inner circumference of Sleeve (A) [29], Hammer Holder (B) [22], Hammer Holder (C) [25], and

the end surface of Spring (A) [6]. Seal 53 g of the special grease into the Cylinder Crank Case [48] (the

Connecting Rod [34] side).

Apply Hitachi Motor Grease No. 29 to the Needle Bearing (M661) [54], the pinion portion of the Armature [70],

the Needle Roller D8 x 20 [5] and the Steel Ball D6.35 [11]. Seal 20 g of the Hitachi Motor Grease No. 29 into

the Cylinder Crank Case [48] (the First Gear [53] side).

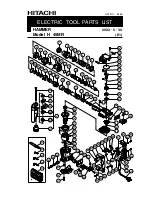

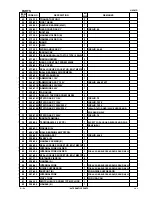

Summary of Contents for H 45MR

Page 26: ......