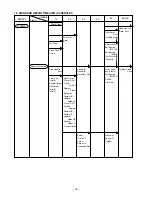

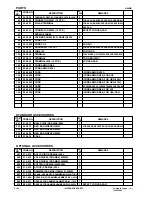

* ALTERNATIVE PARTS

--- 2 ---

ITEM

NO.

CODE NO.

DESCRIPTION

REMARKS

NO.

USED

PARTS

5 -- 02

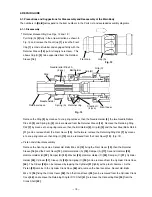

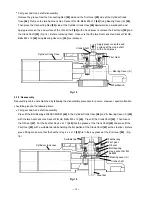

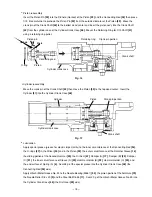

H 45MR

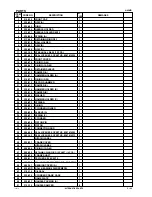

1

315-529

FRONT CAP

1

2

320-802

GRIP (A)

1

3

320-803

RING

2

4

320-804

NEEDLE HOLDER

1

5

313-421

NEEDLE ROLLER D8X20

2

6

320-806

SPRING (A)

1

7

317-088

RETAINING RING D42

2

8

320-810

BALL HOLDER

1

9

320-807

GRIP (B)

1

10

320-808

GRIP (C)

1

11

959-150

STEEL BALL D6.35 (10 PCS.)

4

12

981-942

SEAL LOCK HEX. SOCKET HD. BOLT M6X25

4

13

320-809

FRONT COVER

1

14

980-879

O-RING (S-34)

1

15

990-067

O-RING (1AS-50)

1

16

320-805

RETAINER SLEEVE

1

17

320-812

DAMPER (A)

1

18

320-811

HAMMER HOLDER (A)

1

19

319-572

O-RING (S-25)

1

20

320-813

SECOND HAMMER

1

21

320-817

DAMPER (C)

1

22

320-814

HAMMER HOLDER (B)

1

23

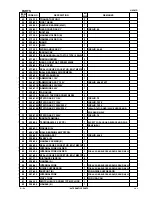

320-815

DAMPER (B)

1

24

320-835

WASHER

1

25

320-816

HAMMER HOLDER (C)

1

26

320-822

STRIKER

1

27

320-823

O-RING

2

28

320-818

CYLINDER HOLDER

1

29

320-820

SLEEVE (A)

1

30

320-821

SPRING (C)

1

31

320-819

CYLINDER

1

32

320-826

PISTON PIN

1

33

320-824

PISTON

1

34

320-825

CONNECTING ROD

1

35

986-940

SEAL LOCK HEX. SOCKET HD. BOLT M6X45

4

36

983-162

SEAL LOCK HEX. SOCKET HD. BOLT M4X12

4

37

HITACHI LABEL

1

38

320-831

CRANK COVER

1

39

HITACHI LABEL

1

40

956-996

O-RING (1AS-60)

1

41

939-540

RETAINING RING FOR D10 SHAFT (10 PCS.)

1

42

320-829

CRANK SHAFT

1

43

930-511

FEATHER KEY 4X4X10

1

44

980-760

SEAL LOCK HEX.SOCKET FLAT HD. BOLT M5X12

2

45

980-761

BEARING COVER (A)

1

46

620-3DD

BALL BEARING 6203DDCMPS2L

1

47

310-119

OIL SEAL

1

48

320-828

CYLINDER CRANK CASE

1

*

49

NAME PLATE

1

50

320-837

HANDLE PACKING (A)

1

51

310-124

HANDLE DAMPER

8

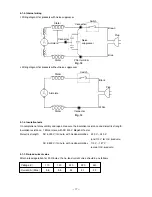

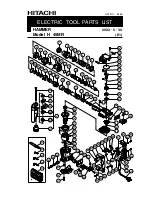

Summary of Contents for H 45MR

Page 26: ......