8

NOTE:

Use a manual hammer to open/close the retainer as it is too heavy to move by hand.

NOTE:

When removing the accessory, such as a bull point, a cutter etc., follow the above procedure

in reverse order.

OPERATION

1.

Pull the trigger switch after applying the tip of the bit to the

crushing position.

In some cases, it is necessary to punch the tip of the bit against

the crushing position forcibly in order to begin the striking

stroke.

This is not due to malfunction of the power tool. It means

that the safe guard mechanism against no-load striking is

working.

2.

Operate this demolition hammer by utilizing its own weight.

The performance will not be better even if it is pressed or

thrust forcibly against the work surface.

Hold this demolition hammer with a force just sufficient to

counteract the reaction.

CAUTION:

Sometimes the power tool does not begin the striking stroke even

when the motor rotates because oil has become thick.

If the power tool is used at low temperatures or if it is used after

a long idle time, this demolition hammer should be kept running

for about five minutes in order to warm it up.

OIL FEEDING

CAUTION:

Prior to oil feeding, always disconnect the plug from the power supply receptacle. Since an

oil chamber is built in this demolition hammer, it can be used for approximately 20 days

without supplying oil, assuming that this demolition hammer is used continuously 3 ~ 4

hours a day.

Feed oil into the oil tank as described below before using this demolition hammer. (See

Figs 5 and 6)

1.

Feed oil without fail before no oil is visible in the oil gauge window when this demolition

hammer is held upright.

2.

Before feeding oil, remove the oil gauge with the provided wrench. Be careful not to

lose the rubber packing attached under the oil gauge.

Fig. 3

Fig. 2

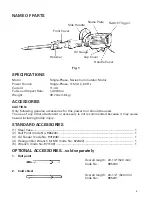

Summary of Contents for H 65

Page 11: ...10 ...