--- 10 ---

8-3. Movement of the Stop Lever

After an extended period of use, the operation of the Stop Lever may become difficult due to incursion of concrete

powder or similar materials into its sliding portion. In such a case, apply oil into the sliding portion between the

Stop Lever and fitting portion of the Front Cover.

8-4. No-load Striking Preventive Mechanism

This machine is so constructed that when the bit end is lifted off the surface being worked, the striker is caught in

the mouth to prevent no-load striking; and when the striker comes off the mouth, a phase difference between the

piston and striker is utilized to reduce the striker's amplitude, thereby preventing the striker from striking the bit as

a double-preventive measure against no-load striking. When the striker is prevented from striking the bit, turn the

switch OFF; then the switch ON again with the bit lightly push the main body on the concrete surface so that the

equipment starts striking.

9. REPAIR GUIDE

9-1. Precautions and Suggestions for Disassembly and Reassembly of the Main Body

The [Bold] numbers in the descriptions below correspond to the item numbers in the Parts List and exploded

assembly diagram.

9-1-1. Disassembly

[NOTE] If it is difficult to loosen and remove the fixing bolts, use an appropriate heat gun, etc. to heat them to

approximately 80 ˚C (176 ˚F).

Disassembly of the Armature Ass'y [61]

(1) Loosen the four Seal Lock Hex. Socket Hd. Bolts M4 x 12 [70], remove the Cap Covers [65], Cap Rubbers

[66] and Brush Caps [67], and take out the Carbon Brushes [68]. At this time, be very careful not to lose the

disassembled parts.

(2) Loosen the four Nylock Hex. Socket Hd. Bolts M8 x 35 [22], and remove the Cylinder Case [20]. Next, after

loosening the Seal Lock Hex. Socket Hd. Bolt M8 x 16 [35], the Connecting Rod Ass'y [38] and Crank Washer

[39] can be disassembled. Leave the Striker [8] and Piston [11] as they are.

(3) Loosen the four Seal Lock Hex. Socket Hd. Bolts M6 x 25 [101], and take off the Handle and Handle Cover

Set [88]. Next, loosen the six Seal Lock Hex. Socket Hd. Bolts M6 x 45 [47], and disassemble the Gear Cover

[40] and Counter Gear [52]. Then, by inserting a flat-blade screwdriver or similar tool into one of the air vents

of the Inner Cover [45] and lifting it upwards, the Inner Cover [45], Armature Ass'y [61], Crank Shaft [37], and

related parts can be removed in a single body.

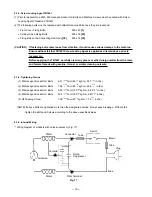

(4) As illustrated in Fig. 6, support the Inner Cover [45] with an appropriate tubular jig, and push down on the end

surface of the armature shaft with a hand press to separate the Armature Ass'y [61] from the Inner Cover [45].