--- 8 ---

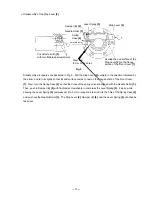

7-3. Grease Replacement

Different kinds of grease are used in the electro-pneumatic hammering section and the speed-change gear

section. It is not necessary to replenish the grease between 6-month (approx.) change intervals unless the tool is

disassembled or there is grease leakage due to a damage or worn seal.

To ensure the smooth reciprocating of the striker and the second hammer, special grease (Part No. 980927

or 981840 or 308471 for impact drill) is used in the hammering section. If the hammering section [inside

the cylinder case and housing (crank shat side)] is disassembled, thoroughly wipe away all old grease

from all parts, and apply 30 g (1 oz) of new grease within the cylinder case and 40 g (1.4 oz) of new grease

within the housing (crank shaft side). Do not exceed the designated amounts of grease. If there is

excessive grease, it may flow between the striker and piston and cause reduced hammering efficiency

and/or increased recoil force.

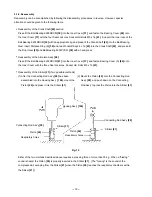

N.P.C. SEP-3A (Part No. 930035) is used in the speed-change gear section (inside the gear cover). The proper

supply amount is 80 g (2.8 oz). Never use the hammering section special grease in the speed-change section.

The special soft grease would leak into the motor section and cause serious problems.

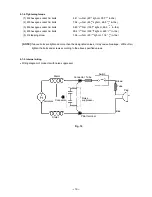

7-4. O-Ring Replacement

The O-ring mounted on the piston is extremely important to ensure adequate sealing of the air pressure.

Although the O-Ring is made of special rubber to ensure a long service life, it does nonetheless become worn and

should be replaced periodically depending on frequency of tool use. With average use, it is recommended that

the O-ring should be replaced every six months to ensure maximum effectiveness.