12

(2) Ma k in g a nd br eak in g capa cit ies

Th e con t a ct or is defin ed by it s m a k in g a n d br ea k in g ca pa cit ies in a ccor da n ce wit h u t iliza t ion ca t egor ies specified in

Ta ble 5.

Th e t est s con cer n in g t h e ver ifica t ion of t h e m a k in g an d br ea k in g ca pa cit ies of t h e con t a ct or a r e in t en ded t o ver ify

t h a t t h e con t a ct or is ca pa ble of m a k in g a n d br ea k in g t h e cu r r en t s st a t ed in Ta ble 9, a n d n ot t o ver ify t h e con t a ct

wear over lon g per iods of opera t ion.

Th e verifica t ion s of m ak in g capa cit y a nd br eak in g capa cit y a r e m a de

a s separ a t e t est s.

1 . Ma kin g ca pacit y

Th e n um ber is 100:50 oper a t ions

of wh ich ar e m ade a t 85% an d 50 oper a t ions at 110% of t h e r at ed coil volt a ge.

2. Br eak in g ca pa cit y

Th e tot a l n um ber of open in g oper a t ion s to be m a de is 25.

Du r in g t ests wit h in t h e lim it s of specified m a k in g a n d br ea k in g capa cit ies a n d wit h t h e specified n u m ber of oper a-

t ions, t h er e sh a ll be n o per m a n ent ar cin g, n o fla shover between poles , n o blowin g of t h e fuse in t h e ear t h circu it a nd

n o weldin g of t he con t acts.

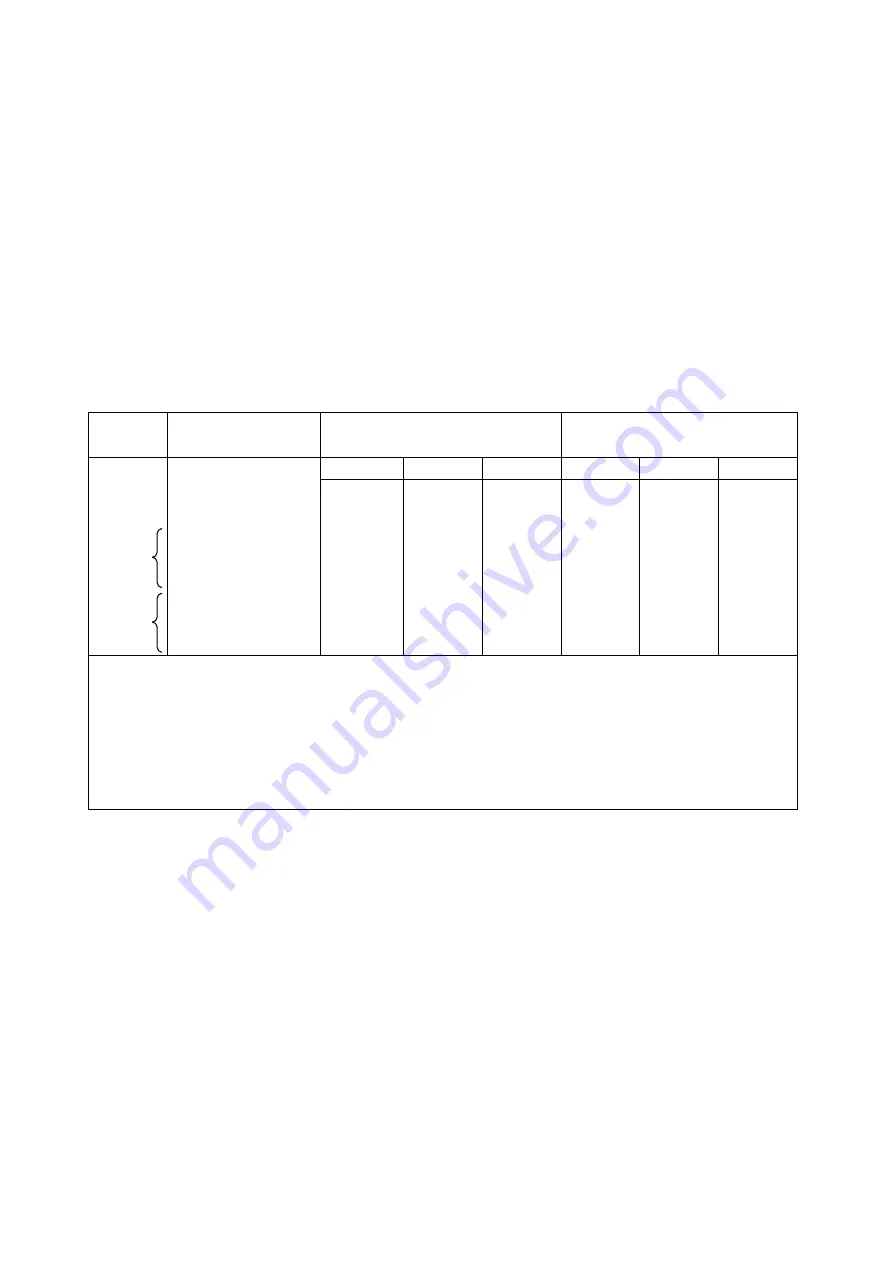

Ta ble 9. Con dit ion s for m ak in g a n d br eak in g corr espon ding t o t h e severa l ut iliza t ion ca t egor ies (IE C 60947-4-1)

Ca t egor y

Va lu e of t h e r at ed

oper at iona l cu rr en t

Mak e

Br ea k

I/Ie

U /Ue

cos

φ

(1)

Ic/Ie

U r /U e

cos

φ

(1)

AC-1

AC-2

AC-3

AC-4

(All valu es)

(All valu es)

Ie

≦

17A

17 A < Ie

≦

100 A

Ie > 100 A

Ie

≦

17A

17 A < Ie

≦

100 A

Ie > 100 A

1.5

4

10

10

8 (2)

12

12

10 (4)

1.1

1.1

1.1

1.1

1.1

1.1

1.1

1.1

0.95

0.65

0.65

0.35

0.35

0.65

0.35

0.35

1.5

4

8

8

6 (3)

10

10

8 (2)

1.1

1.1

1.1

1.1

1.1

1.1

1.1

1.1

0.95

0.65

0.65

0.35

0.35

0.65

0.35

0.35

Ie; Rat ed oper at iona l cu r ren t

U; Volt a ge befor e m ak e

U e; Ra ted oper at ion a l volt a ge

U r; Recover y volt a ge

I; Cu rr en t m a de

Ic; Cur r ent br ok en .

1) Toler an ce for cos

φ

:

±

0.05

2) Wit h a m inim um of 1000 A for I or Ic.

3) Wit h a m inim um of 800 A for Ic.

4) Wit h a m inim um of 1200 A for I.

(3) Mech an ica l endu r an ce

Wit h r espect t o it s r esist a n ce t o m ech a n ica l wea r, t h e cont a ct or is ch a r act er ized by t he n um ber of n o-load oper a t in g

cycles (i.e., wit h ou t cu r r en t on t h e m a in con t a ct s) wh ich ca n be m a de befor e it becom es n ecess a r y t o s er vice of

r eplace a n y m ech a n ica l pa rt s.

Th e con t a ct or sh a ll be inst a lled as for n orm a l ser vice; in pa r t icu la r, t h e condu ct or s sh a ll be con n ected in t he s a m e

m a n n er as for norm a l u se.

Th e coils of t h e con t r ol elect r o-m a gn et s sh a ll be su pplied a t t h eir r a t ed volt a ge a n d, if a pplica ble, a t t h eir r a t ed

fr equen cy.

Summary of Contents for H100C

Page 2: ......

Page 9: ...5 Fig 1 H35 Horizontal Plunger type Fig 2 H300C Link structure ...

Page 36: ...32 Fig 28 ...

Page 54: ......