14

(i) t h e iron core of t h e electr om a gn et is da m a ged by a st r on g sh ock, a n d t h e fat igu e of m olded par t s a n d pr essed

p a r t s becom es gr ea t er , w it h t h e r es u lt t h a t t h e m ech a n ica l en d u r a n ce of t h e con t a ct or is s h or t en ed by

a pproxim a t ely 50%.

(ii) th e con ta ct incr easin gly ju m ps du e t o t he str on g sh ock a n d t h er e is a possibilit y of a bn or m al wear an d

con t act weldin g du e t o ma kin g a nd br eak in g of st ar t in g cur r en t of t h e mot or .

(2) Wh er e t h e power sou r ce volt a ge is lower t h a n t he r a t ed volt a ge

Wh en t h e power sou r ce volt a ge is low, it nea rs t h e closin g volt a ge (lower t ha n 85% of t he r a t ed volt a ge) of t h e con-

t a ctor. As a r esu lt, a ca se occur s wher ein t h e elect r om agn et is n ot at tr a ct ed t o t he fu llest ext en t beca use of va r ia t ion

of volt a ge, volt a ge dr op du e t o r ush cu rr en t of coil, a nd t h e lik e, so t h a t t he con t act flut t ers a n d t r ou bles m a y be

ca u sed in clu din g a bn or m a l con t a ct wea r a n d con t a ct weldin g, or bu r n in g of coil (beca u se t h e r u sh cu r r en t of coil

flows for a lon g t im e).

Mor eover, t h e mot or m a y in cur fa ilur es su ch as bu r n in g cau sed by cont in u ous flow of st a r tin g cu r ren t .

Th e st ar t in g cu r ren t of t h e m ot or ca u ses volt a ge dr op if t he wir e of t h e m a in cir cu it is lon g or fine, so t h e volt age of

coil becom es lower t h a n 85% of t h e r a t ed volt a ge, a n d t h e sam e ph en om en on as a bove m a y t a k e pla ce ; a t t en t ion

sh ou ld be pa id t o t h is poin t. Th e ca uses of volt a ge drop of power sou r ce a t closin g ar e sh own in Table 11 , so t h a t

t h ey sh ou ld be in vest igat ed a nd m easu res a ga inst t hem t ak en.

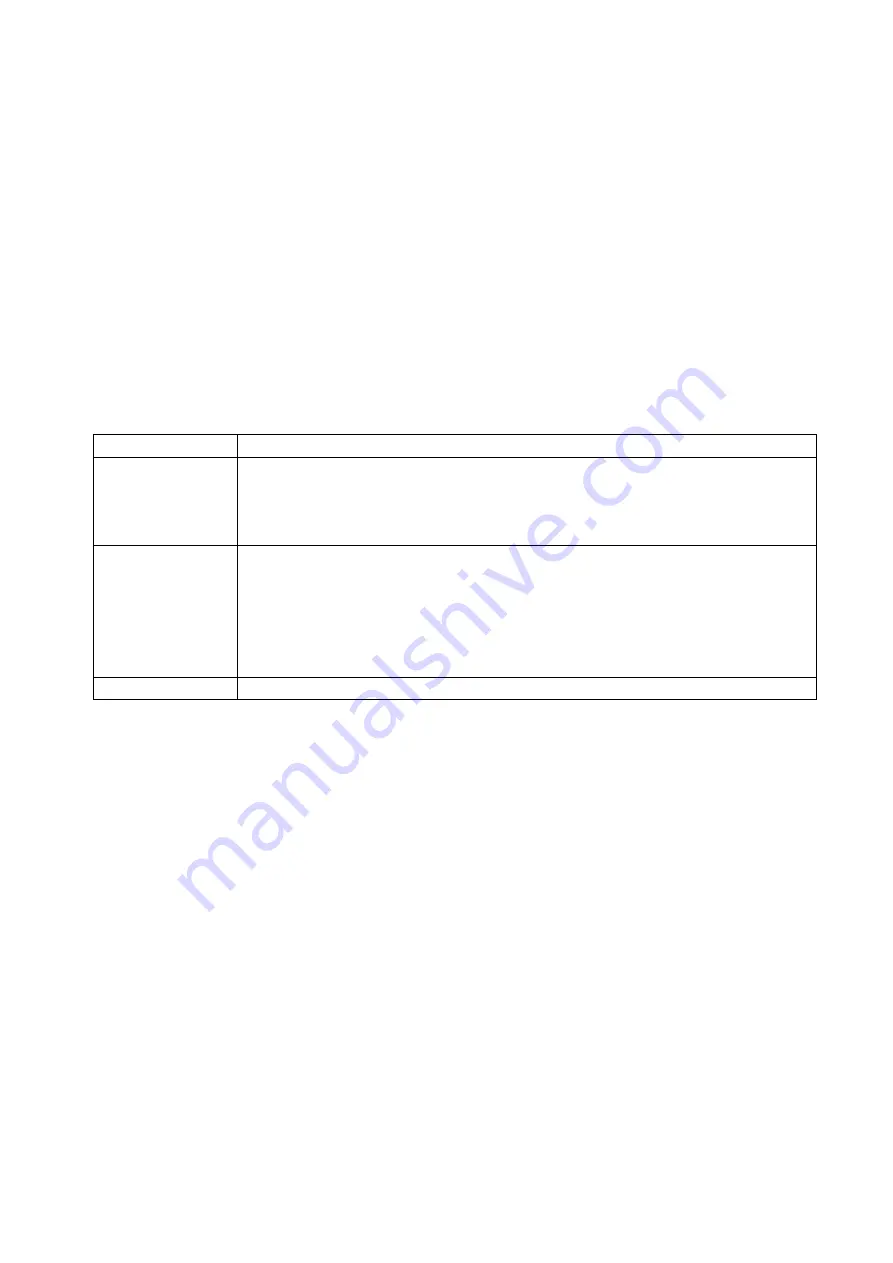

Ta ble 11. Ca uses of volt a ge dr op of coil power sou rce

Cla ss

Ca u ses

Ma in cir cu it

・

Th e wir e of m a in cir cu it is fin e, so t h e volt a ge is dr opped by t h e st a r tin g cu r ren t

of t h e m ot or .

・

Th e wir e of m a in cir cu it is lon g, so t he volt a ge is dr opped by t h e st ar t in g cur r ent

of t h e m ot or .

Oper a tin g cir cu it

・

Th e wir e of oper a t in g cir cu it is fin e, so t h e volt a ge is dr opped by t he r u sh cur r ent

of t h e coil.

・

Th e wir e of oper a t in g cir cu it is lon g, so t he volt a ge is dr opped by t he r u sh cur r ent

of t h e coil.

・

Th e capa cit y of power sour ce t r a n sfor mer for oper a t in g cir cu it is shor t, so th e

volt a ge is dr opped by t he r u sh cur r en t of t he coil.

P ower sour ce

・

Th e volt a ge r egu lat ion of power sou r ce is la r ge.

2-3-2 Oper at in g Tim e

Cit ed below a re t he it em s to wh ich a t ten t ion shou ld be pa id when h a ndlin g th e closin g a n d r eleasin g t imes of t h e

con t act or .

(1) Closin g a n d r eleasin g t im e

Th e closin g a n d r eleasin g t im es of t h e cont a ct or va r y from 10 t o 50 ms as sh own in t h e ca t a log. Th is is du e t o t h e

ph a se a nd valu e of volta ge applied t o t h e coil a nd t h e frict ion of t h e mech a n ica l sect ion . E xam ples of t hese var iat ions

a r e as shown in F ig. 14.

Wh er e it is not desir ed t h a t two elect r ica l sign a ls a re sequ en t ially la pped, t he cont a ct or is pla ced in t h e ot h er cir cu it

t o crea t e a t im e la g. H owever, t h is t im e la g is not a st r ict t im e differ en ce, but on e wh ich is used as a ppr opr iat e wh en

a n a ppr oxim at e t im e la g is wa n t ed.

Wh ile, if t his closin g or releasin g t im e is used in pla ce of a t im er t o get t h e a ccu r at e t im e la g, n o degr ee of a ccu r a cy

ca n be expect ed beca u se of t h e a bove-m en t ion ed va r ia t ion fr om 10 t o 50 m s. At t en t ion , t h er efor e, sh ou ld be pa id

t o t h is point .

Summary of Contents for H100C

Page 2: ......

Page 9: ...5 Fig 1 H35 Horizontal Plunger type Fig 2 H300C Link structure ...

Page 36: ...32 Fig 28 ...

Page 54: ......