43

(b) P er iodica l inspect ion it em s

Th e per iodica l in spect ion s h ou ld be ca r ried out for th e it em s given in Ta ble 32.

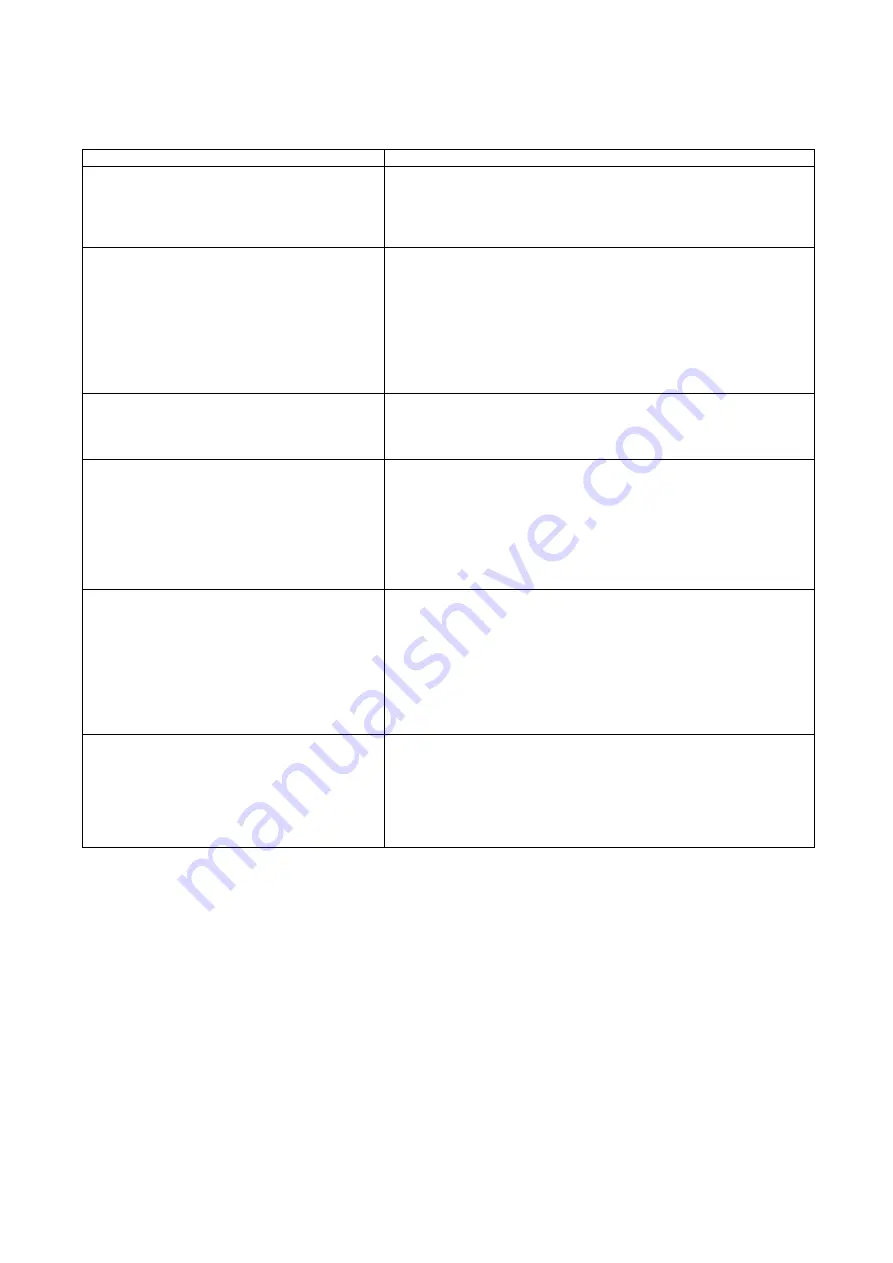

Ta ble 32. P eriodica l inspect ion it em s

P er iodica l inspect ion it em

Con t en ts of inspect ion

1. Tight en in g of s cr ews

・

Ch eck t h e ter m in a l cla mpin g scr ew a n d con du ct or

con n ect in g scr ew for loosen in g, an d t ight en t h em

fu r t her. Also check t h e t er m in a ls t o which n o wir e

is con n ect ed; u nless ch ecked, t h er e is a possibilit y

t h a t t h ey will fa ll ou t a nd ca u se t r ou bles.

2. Rem oval of dr opped for eign

su bst a nces, s uch a s dust , ch ip,

wirin g wast e, scr ew wa sher,

et c.

・

Con firm t h a t t her e a re no con duct ive for eign

su bst a nces in t he m olded pa rt bet ween t he t er-

m in a ls or in ot her places.

・

Ch eck for a dh er en ce of dust, oil, et c. If su ch

for eign m a t t ers a r e fou n d, in vest igat e t h e ca use

of t h eir pr esence.

・

Ch eck wh et her t h e window of t h e a rc suppressin g

ch a m ber of con t act or is blocked by a for eign

su bst a nce .

3. Check of a bn or m al t em per a t ur e

r ise

・

Ch eck wh et her t h er e is discolor a t ion of t h e con -

du ct ive pa rt du e t o a bn orm a l t em per a t ur e r ise,

or discolor a tion a n d cr a ck of t he m olded pa r t du e

t o over h eat in g.

4. Check of t h er ma l over loa d r ela y

・

Ch eck t h e ter m in a l scr ews for loosen in g.

・

Ch eck t h e oper a t in g st a te by per form in g t est

t r ip a nd r eset t in g.

・

Wh en t he con t a ct of t h e cont a ct or is alm ost

m elt ed due t o sh or t cir cu it , t he t h erm a l over load

r ela y m ust be considera bly dam a ged, so t ha t it

sh ou ld be r epla ced. (E xclu din g t h ose wh ich a r e

pr otect ed by CT or sa t ur a tion r eact or .)

5. Check of m an u a l oper a t ion, a nd

ch eck of oper at ion al sou nd or

bea t a t t im e of a ut om a t ic

oper at ion

・

Tu r n off t h e power a nd m ove t h e m ovin g par t

by h a n d. Ch eck whet her t h e movin g pa r t m oves

smoot hly .

・

Ch eck wh et her a bn or m al oper a t ion a l sou n d or

bea t a r e gen er a t ed by a ut om a t ic oper a t ion . If t he

oper at ion is done by open in g t h e insu lat ed

cover, t r oubles su ch as sh or t cir cu it , et c. m a y

occu r, so a bsolu t ely a void in it ia t in g t h e a bove

oper at ion .

6. Check of cont a ct an d t im e of

r eplacem en t

・

Ch eck wh et her t h e con t act is a bnorm a lly wor n.

Wh en t h e cont a ct is r em a rk a bly wor n , r eplace t h e

con t acts of a ll ph ases even if t he con ta ct of on ly

on e ph ase is wor n. If on ly t h e cont a ct of on e pha se

is r epla ced, a failu re will occur beca use t h e t hick -

n ess of t h e con t act of on e ph a se is differ ence fr om

t h a t of t h e ot h er ph ase.

Summary of Contents for H100C

Page 2: ......

Page 9: ...5 Fig 1 H35 Horizontal Plunger type Fig 2 H300C Link structure ...

Page 36: ...32 Fig 28 ...

Page 54: ......