Chapter 10 PLC Installation, Mounting, Wiring

10-4

(3)

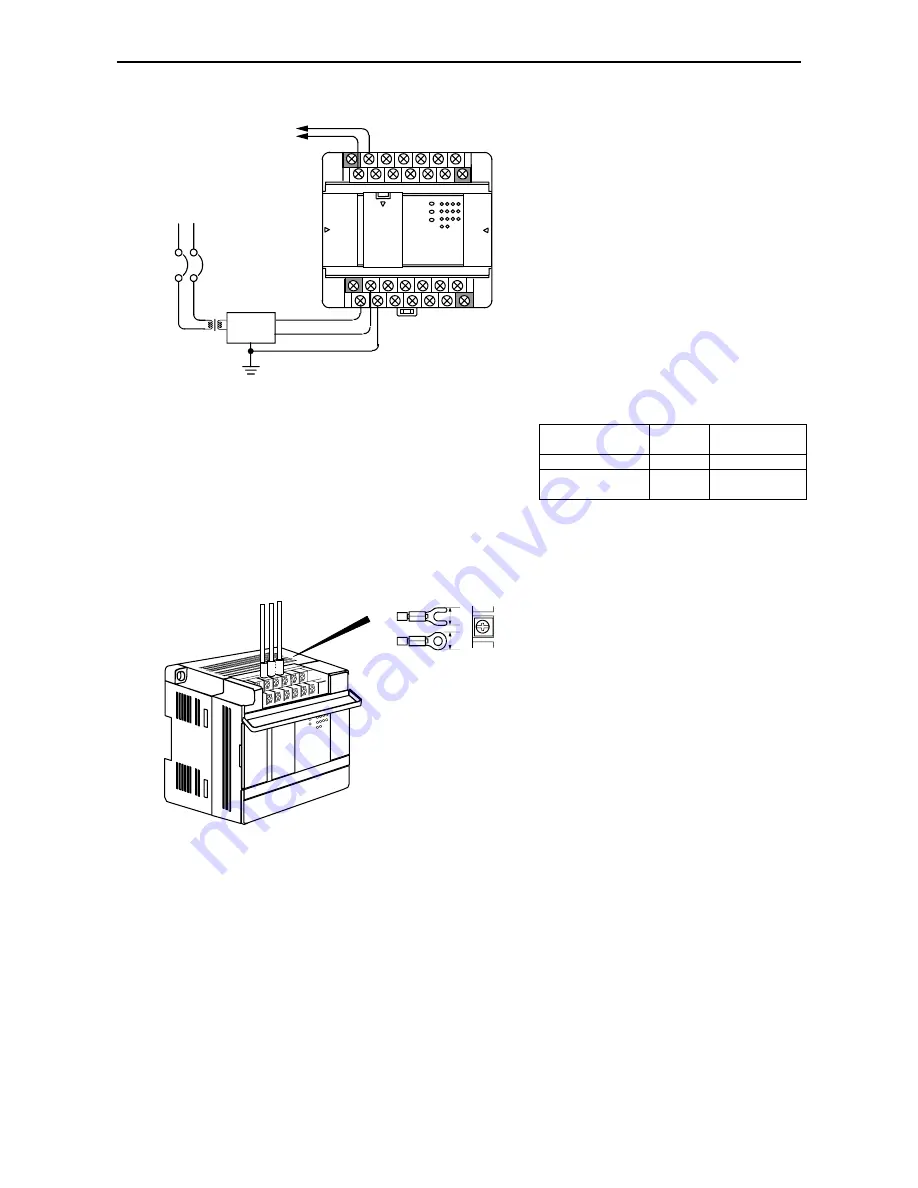

Wiring to the power module

100 V AC to

240 V AC

Power supply

for the sensor

Power leakage

breaker

Shielded

insulated

transformer

Noise

filter

Figure 10.4 Power supply wiring diagram

(a) For power supply wiring, use a cable of 2

mm

2

or more to prevent a voltage drop from

occurring.

(b) For the function ground terminal (PE

terminal), use a cable of 2 mm

2

or more and

provide Class D grounding (100

Ω

or less).

The appropriate length for the ground cable

is within 20 m.

1] Instrumentation panel and relay panel

grounding may be shared.

2] Avoid grounding shared with equipment

that may generate noise such as high-

frequency heating furnace, large-scaled

power panel (several kW or more),

thyristor exchanger, electric welders, etc.

3] Connect a noise filter (NF) to the power

cable.

(c) Tighten the terminal screws within the torque

range as shown below.

Unit

Screw

Clamping

torque

10-point

M2.5

0.3 to 0.4 N

x

m

14, 23, 28-point,

expansion

M3.0

0.5 to 0.6 N

x

m

(d) Use the same power supply system for the

basic and expansion units.

(4)

Wiring cable for I/O signals

6

6

Tighten each terminal screw using a torque of the

specified torque range.

When using a crimp terminal, use one with an

outer diameter of 6 mm or less.

Use only up to two crimp terminals in the same

terminal. Avoid clamping down more than three

at the same time.

Only one piece of cable can be wired per

terminal if the cable type is between AWG14 and

AWG22 (cable thickness ranging between 2.1

mm

2

and 0.36 mm

2

), but two pieces can be wired

if the cable type is between AWG16 and AWG22

(between 1.3 mm

2

and 0.36 mm

2

).

Summary of Contents for HIDIC MICRO-EH

Page 1: ...HITACHI PROGRAMMABLE CONTROLLER APPLICATION MANUAL NJI 350B X ...

Page 12: ...MEMO ...

Page 14: ...Chapter 1 Features 1 2 MEMO ...

Page 50: ...Chapter 4 Product lineup and wiring 4 18 MEMO ...

Page 196: ...Chapter 5 Instruction Specifications 5 146 ...

Page 263: ...Chapter 11 Communication Specifications 11 10 MEMO ...