Chapter 15 Daily and Periodic Inspection

15-1

Chapter 15 Daily and Periodic Inspections

In order to use the functions of the MICRO-EH in the optimal conditions and maintain the system to operate normally, it

is essential to conduct daily and periodic inspections.

(1)

Daily inspection

Verify the following items while the system is running.

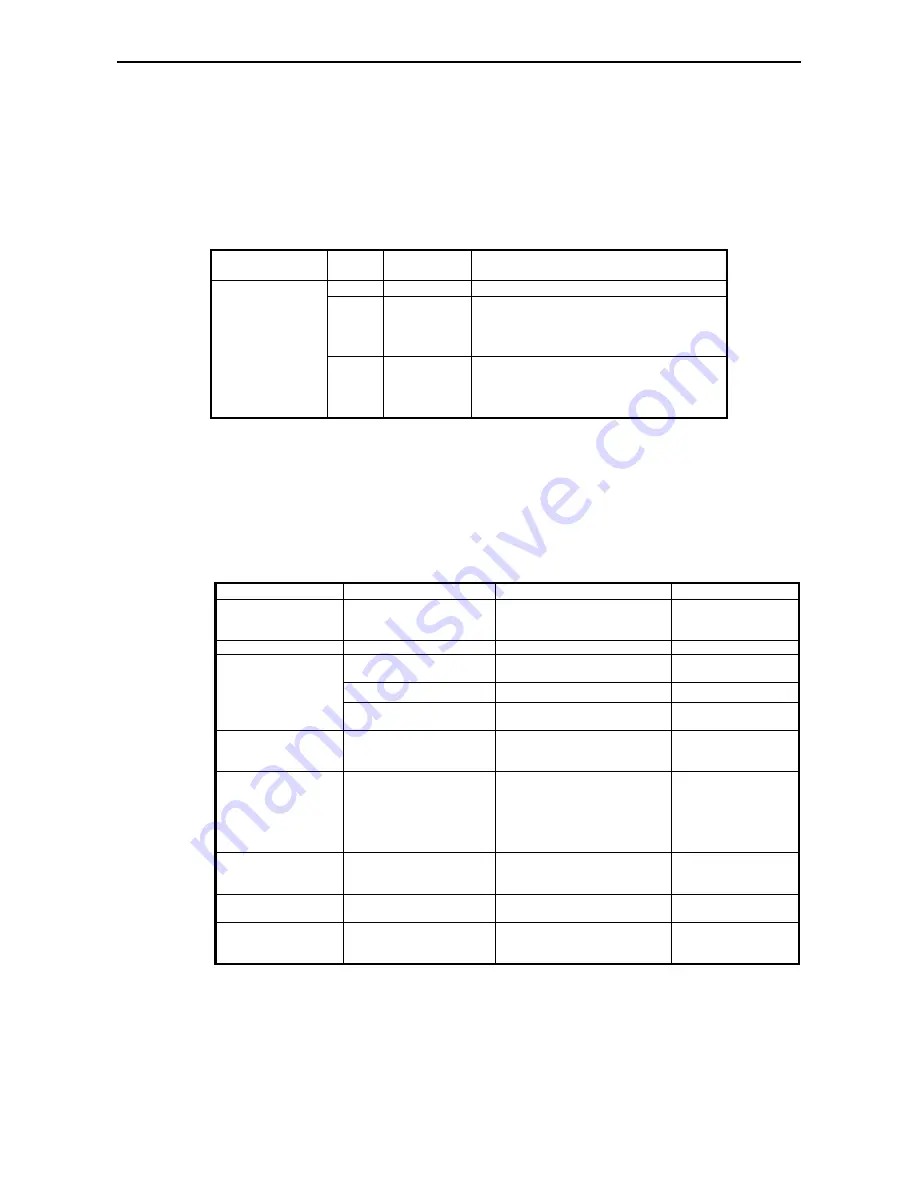

Table 15.1 Items for daily inspection

Item

LED

display

Normal status

Main cause of error

POW

Lighting

Power supply error, etc.

RUN

Lighting

(in RUN

status)

When not lit:

Microcomputer malfunction, memory error, etc.

When flashing:

Syntax error, congestion error, etc.

Unit LED display

*1

OK

Lighting

When not lit:

Microcomputer malfunction, memory error, etc.

When flashing:

Battery error *2

*1:

The MICRO-EH indicates the error contents using the combination of lit/flashing/not lit status of OK and

RUN lamps. For details, see the error code list in Chapter 12.

*2:

If the power supply for the basic unit is left turned off without replacing the battery after the OK lamp was

flashing, the memory contents may be destroyed. Exercise caution when the system power is turned off for a

long period of time, since this error may not have been detected and the memory contents may have already

been destroyed.

(2)

Periodic inspection

Turn off the power for the external I/O circuit and check the following items once every six months.

Table 15.2 Items for periodic inspection

Part

Item

Check criteria

Remarks

Programming device to

CPU

Check operation of

programming device

Must be able to be connected online.

All switches and display lamps work

normally.

Power supply

Check for voltage fluctuations

85 to 264 V AC

Tester

I/O module

Output relay life

Electrical life

200,000 times

Mechanical life 20 million times

See the relay contact life

curve (Chapter 10).

LED

Turns on/off correctly

External power voltage

Within the specification for each I/O See the I/O specifications

(Chapter 6).

Battery

(Lithium battery)

Check voltage and life

Is the OK lamp flashing?

Check to see if it has been less than

2 months since the last exchange.

Installation and

connecting areas

(1) All modules are securely

fixed

(2) All connectors fit snugly

(3) All screws are tightened

(4) Damage and deterioration

of each cable

There should be no problem.

Tighten

Check insertion

Tighten

Visual check

Ambient environment

(1) Temperature

(2) Humidity

(3) Other

0 to 55

°

C

5 to 95 % RH (no condensation)

No dust, foreign matter, vibration

-

Spare parts

Check number of parts, storage

condition

There should be no problem.

-

Program

Check program contents

Compare the contents of the latest

program saved and CPU contents,

and make sure they match.

Check both master and

backup.

(3)

Life of the power module

Numbers of electrolytic condensers are used in the power module. Electrolytic condensers have a lifetime and it is

believed that the life is reduced by half when the ambient temperature rises 10

°

C.

When stocking spare parts, the standard for consideration is that the power module has a life of approximately five

years when used at the rated ambient temperature (30

°

C). Also, to extend the life of the module, consider the air

circulation around the module and ambient temperature when installing it.

Summary of Contents for HIDIC MICRO-EH

Page 1: ...HITACHI PROGRAMMABLE CONTROLLER APPLICATION MANUAL NJI 350B X ...

Page 12: ...MEMO ...

Page 14: ...Chapter 1 Features 1 2 MEMO ...

Page 50: ...Chapter 4 Product lineup and wiring 4 18 MEMO ...

Page 196: ...Chapter 5 Instruction Specifications 5 146 ...

Page 263: ...Chapter 11 Communication Specifications 11 10 MEMO ...