S U B J E C T

S P E C I F I C A T I O N

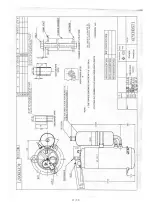

M o d e l W H P 1 1 5 0 0 V S D P C 9 E Q

PAGE:3/30

2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

q

5.44 5.39 5.34 5.29 5.24 5.18 5.12 5.06 5.00 4.95 4.89 4.83 4.78 4.72 4.66

d

3.71 3.65 3.65 3.64 3.63 3.61 3.59 3.56 3.54 3.51 3.48 3.45 3.42 3.39 3.36

4. CHARACTERISTICS

4.1. Appearance

The surface of the compressor is painted to black, without obvious flaw ,impact scar, paint peel

off, rust and so on.

4.2. Indication

Compressor model type, manufacturing data are clearly indicated on the surface of compressor。

4.3. Residual moisture

300mg MAX

4.4. Residual impurities

150mg MAX

4.5. Dielectric withstand

A 1500V alternating voltage for 1minute should be applied between live parts and dead metal parts.

3.4

Inductance Ld

(

mH

)

Sheet 2

——

3.5

Inductance Lq

(

mH

)

Sheet 2

——

3.6

S t a t o r c o i l r e s t i s t a n c e

20

℃

(

Ω

)

0.502

(

20

℃)

line-to-line

3.7 Voltage Constant

(

Vrms/krpm

)

43.10V/krpm

line-to-line

3.7

Torque Constant

(

N

·

m/Arms

)

0.69

Torque/Current

3.9

Inertia

(

Kg

·

m2

)

0.000666

3.10

Flux

Φ

a

(

Wb

)

0.1702

φ(Per Phase,Peak)=

3

2

0

2

f

E

π

×

φ(一相 peak 值)=

3

2

0

2

f

E

π

×

3.11

Magnet Material

NdFeB

Electric Current

Summary of Contents for Highly WHP11500VSD

Page 8: ...Arbeitsbereich siehe Bild 1 20 C A ...

Page 19: ...17 30 ...

Page 20: ...18 30 ...

Page 21: ... 19 30 ...

Page 22: ...20 30 ...

Page 23: ...21 30 ...

Page 24: ...22 30 ...

Page 25: ...23 30 ...

Page 26: ...24 30 ...

Page 27: ...25 30 ...

Page 28: ...26 30 ...

Page 30: ...28 30 ...

Page 31: ...CHART 3 Instructions forInverter rotary compressor revolutions change 29 30 ...