19

4. DAILY CHECK [Lubricant Management]

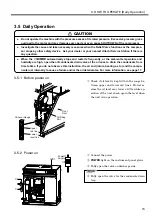

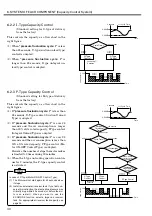

4.3.2 How to change oil

q

Press the STOP button.

w

Disconnect the power.

e

Be sure that the pressure in the compressor is

decreased to the ambient pressure level (Check if

the Pressure Gauge indicates 0 MPa).

r

Detach the door and the right enclosure panel.

t

Unplug the oil-draining pipe on the pipe extended

from the oil case.

y

Place the oil pan under the oil-draining valve. Open

the oil-draining valve. Let the oil be totally drained

from the oil case. Close and plug the oil-draining

valve.

u

Place the oil pan under the oil cooler's plug. Un-

plug the oil cooler. Let the oil be totally drained

from the oil cooler. Plug the oil cooler.

i

Unplug the oil filling port. Fill the genuine synthetic

oil (NEW

A

OIL 2000) into the oil cooler,

until the oil reaches the upper red line on the oil

level gauge.

o

Make sure that all the plugs are tightly screwed,

and return the door and the right enclosure panel

to their original places.

!0

Turn the POWER ON. Press the START button

and stop it 7 or 8 seconds later.

!1

Check the oil level with the oil gauge of the oil

case. The level will lower because some of it is

circulating in pipes or oil cooler.

!2

Confirm that the pressure decreases to the level

of the ambient air pressure. Then turn the

POWER OFF and replenish some more lubricant

into the replenish port.

!3

After replenishment, fasten the plug on the re-

plenish port securely.

!4

Press the START button again to check the oil level

when the compressor is at its full load.

Discharge

Check and Replenishment

Filling the oil

●

Replace the lubricant in whole every two

years.

●

Be sure to drain oil in use (old oil) with

condensate in whole before replacement.

●

Be sure to use genuine synthetic oil (NEW

A

OIL 2000) for lubricant.

CAUTION

●

If oil is so deteriorated as to produce the sludge or to be green, you can not recover the system’s

function even by cleaning the oil cooler, oil case and oil piping. You may have to replace the oil cooler

and overhaul the entire system (including the air end).

●

Optional Low Oil Level Alarming Feature:

If the ALARM light flashes and the error code E-22 is displayed on the digital monitor, stop the

A

, make sure that the system has been depressurized, and turn off the main power; then add

oil. Restart and fully load the

A

; then press the RESET button.

CAUTION

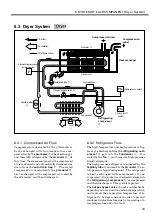

Oil Filling Port

Oil Case

Oil Case

Draining Port

Oil Cooler Draining Port

(Located under the

right enclosure panel)

Oil Level

Gauge