25

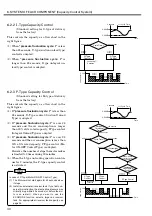

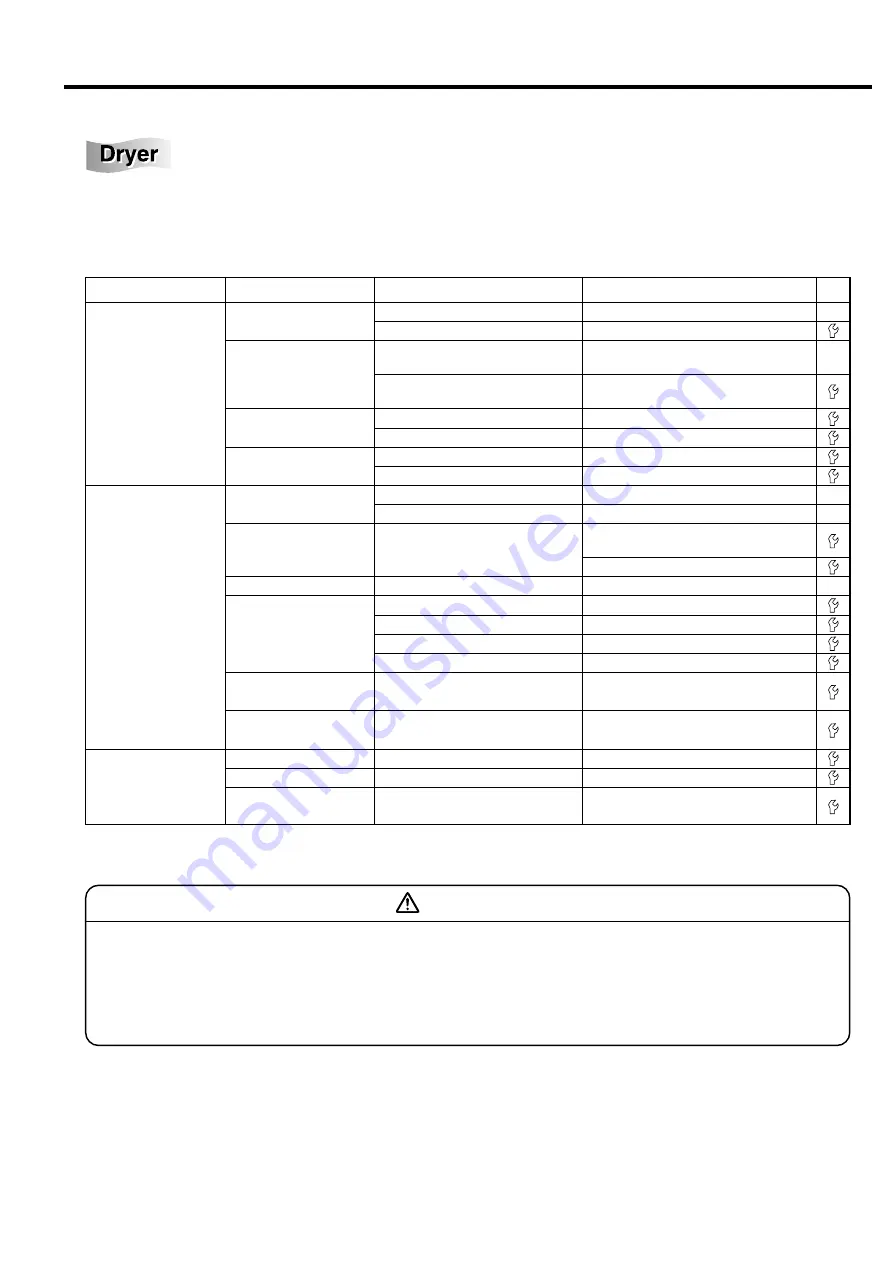

5. TROUBLESHOOTING [SHUTDOWN/ALARM Indications on the Instrument Panel]

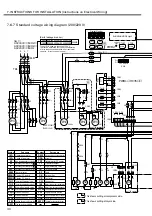

Check the power supply voltage.

Check the PS1 for an operation.

Check the power supply terminal

screws for looseness.

Check the contactors for roughness of

their contacts.

Check the refrigerant compressor for seizure.

Check the insulation resistance.

Check the operating current.

Check the wires for looseness.

Check the ambient temperature.

Check the cooling system of the air compressor.

Read the refrigerant pressure gauge.

Check the condenser fins for dirtiness.

Check the fan control switch PS2 for a failure.

Check the 49FC for continuity.

Check the IM4 and/or IM5 for continuity.

Check the contactors for a failure.

Check the evaporator for a refrigerant leak.

Check the continuity.

Check the system for a refrigerant leak.

Check the OHR for continuity.

Check the hot-gas bypass valve for

degree of opening.

Operating current: High

Power cables: Connected

in a single phase.

Parts of refrigerant

compressor: Failed.

49FC: Failed.

Incoming compressed air:

High in temperature.

Hot-gas bypass valve:

Failed.

Condenser fins: Dirty.

Cooling fan motor for

condenser IM4 and/or

IM5: Not working.

Non-condensable gas:

Mixed in the refrigerant paths.

Parts of pressure switches

PS1 and/or PS2: Failed.

Refrigerant: Leaked.

OHR: Failed.

Incoming refrigerant: High

in temperature.

Keep the operating voltage as specified.

Refer to the (2).

Retighten the terminal screws.

Replace the contactors.

Replace the refrigerant compressor.

Replace the refrigerant compressor.

Replace the 49FC.

Tightly reconnect the wires.

Reduce the ambient temperature to below 40

°

C.

Clean the condenser and/or replace the cooling fan.

Adjust the hot-gas bypass valve to correctly

set a refrigerant pressure.

Replace the hot-gas bypass valve if it is not adjustable.

Clean the condenser fins.

Replace the PS2.

Replace the 49FC.

Replace the IM4 and/or IM5.

Replace the contactors.

Clean the refrigerant paths and replace the

air cooler.

Replace the PS1 and/or PS2.

Take a corrective measure, and charge the refrigerant.

Replace the OHR.

Adjust the hot-gas bypass valve to correctly

set a refrigerant pressure.

■

Troubleshooting after the DRYER Light Flashes

When a problem occurs on the built-in air dryer, the

DRYER

light flashes and the digital monitor displays a

corresponding ALARM or SHUTDOWN code. If this is the case, refer to the following table to identify the cause.

After solving the problem, press the

RESET

button to reset the control circuit.

(1) Operation of thermal

overload relay 49FC

(2) Operation of

high-pressure

pressure switch PS1

(3) Operation of

refrigerant

thermostat OHR

Causes

What to Check

Mark

Symptoms

What Actions to Take

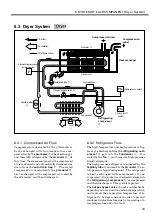

The built-in air dryer uses non-flammable, non-toxic, and odorless refrigerant (Freon gas R-407C). The

Freon gas leak from the system, however, may generate toxic gas by contact with fire and it may irritate

the eyes and throats. In addition, it covers the floor because it is larger in specific weight than the air,

which may cause oxygen deficit to the personnel. When the Freon gas leaks, therefore, extinguish the fire,

ventilate the room with a sweep-the-floor motion, and contact a Hitachi distributor.

WARNING