49

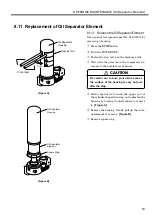

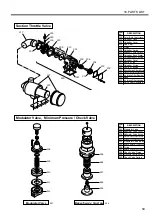

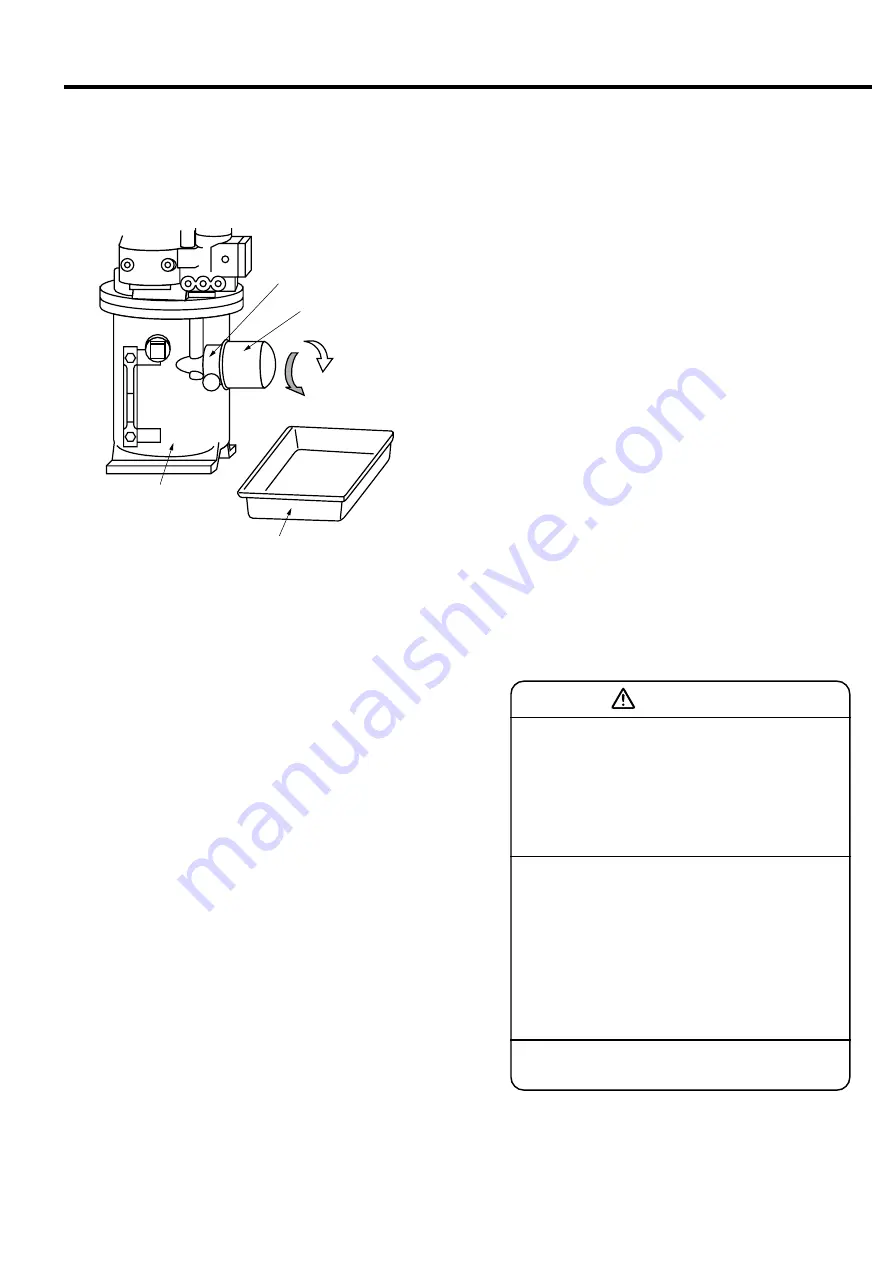

8.7 Replacement of Oil Filter Element

q

Press the

STOP

button.

w

Turn the POWER OFF.

e

Close the Stop Valve on the discharge side.

r

Wait for the inner pressure of the compressor

depressurized to the level of ambient air.

t

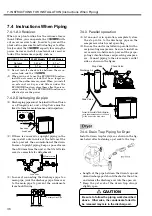

Place a saucer to receive lubricant.

y

Check the oil level gauge for oil level. If it is

higher than the oil filter element’s center, re-

move the oil from the oil case as required.

u

Unfasten and remove the oil filter by a tool

like filter wrench.

i

Take a gasket of new oil filter element, and

spread lubricant on it, then screw it in the

head as before.

o

Fasten the element by the hand without use of

a tool like filter wrench.

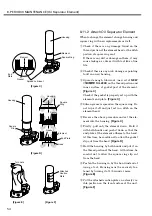

8. PERIODIC MAINTENANCE [Oil Filter Element]

●

If a tool like filter wrench or pipe wrench

is used to fasten the oil filter element,

element’s housing part may be damaged

or deformed, and will cause leak or

breaking. Be sure to fasten it by the

hand tightly.

●

When the Oil Filter clogged, lubricant

supply to the compressor lessens and

discharged air temperature rises.

This makes Discharge Temperature Re-

lay to actuate and the compressor even-

tually stops. Also, lubricant feeding to

the bearings becomes insufficient and

this may cause shutdown of the unit.

●

Be sure to change oil filter element peri-

odically.

CAUTION

Oil Case

Head

Oil Filter Element

Saucer

Close

Open