55

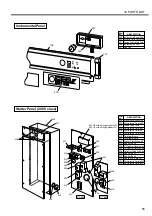

8. PERIODIC MAINTENANCE [Belt]

8.12 Inspection of Belt

When the belt tension is lowered, it slips and pro-

duce noise or larger vibration of the belt during

operation. Periodic check on the belt is needed.

Item

Load P

Bending

δ

Tension

Be sure to stop the unit and turn the power

OFF before inspecting the belt. Keep your

hand or other things away from the unit

while operation, or such action will cause

serious injury to the personnel.

WARNING

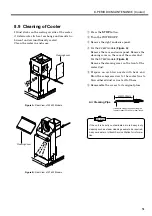

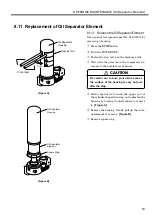

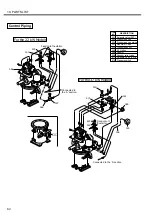

8.12.1 Visual Check of Belt and V-Pulley

q

Throw the light on the belt while moving and

check if there is any missing of rib or crack on it.

Likewise, check if there is any abnormal wear

or damage to the working surface of the V-pul-

ley and M-sheave.

w

Check if no slipping noise (squeaking noise or

creaking noise) is produced by the belt at

starting or while operation.

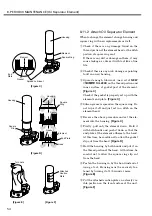

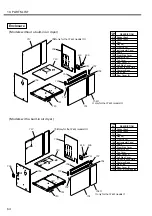

8.11.2 Measurement of Belt Tension

q

Prepare a flat plate (with length of about 600 mm).

w

Press the plate towards belt span surface of V-

pulley and M-sheave, then using a tension

meter to measure the pressing load and bend-

ing displacement at its span center.

If the bending is kept within the range shown

in the left table, there is no need for tension

adjustment. If deviation from the stated val-

ues is obvious, tension adjustment is needed.

Ask your dealer or Hitachi service station for

the adjustment.

e

It is possible to use a special tension meter to

measure tension of the belt directly. Ask your

dealer or Hitachi service station for more de-

tail of this measurement.

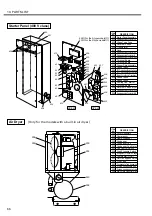

Do not adjust the belt tension too tightly.

Failure to observe this instruction may re-

duce the service life of the belts and/or

cause an unexpected accident.

CAUTION

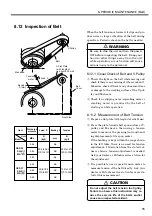

0.69

0.84

0.92

0.69

0.84

0.92

58.8 to 98.1

883 to 1471

(6 to 10)

(90 to 150)

49 to 78.4

735 to 1177

(5 to 8)

(75 to 120)

Unit

Model

OSP-22

SA(R)

I

MA(R)

I

OSP-37

SA(R)

I

MA(R)

I

6.8

6.6

6.4

6.9

6.9

6.8

N

(kgf)

mm

MPa

N

(kgf)

Discharge

pressure

V-Pulley

Belt

Belt

Cover

M-sheave

A Flat Plate

(with length of

about 600 mm)

Tension

meter

Load P

Bending

δ

(mm)

Front Side