61

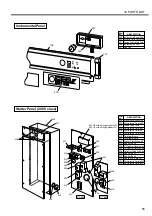

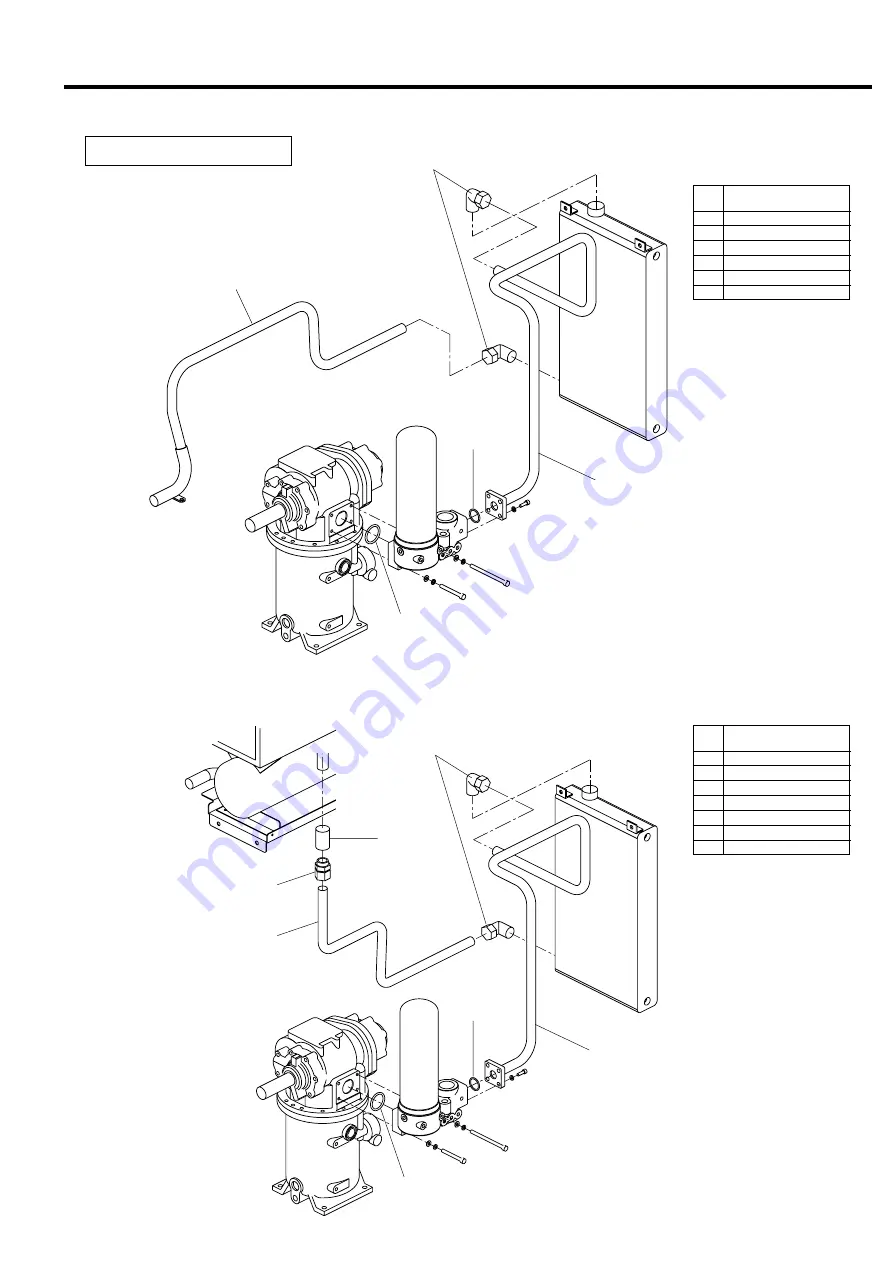

10. PARTS LIST

551

561

663

666

667

687

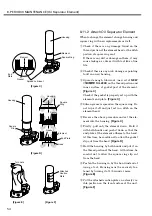

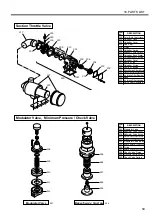

O-ring

Discharge Pipe (2)

Discharge Pipe (1)

Joint, straight

Joint, elbow

O-ring

Discharge Air Piping

ITEM

NO.

DESCRIPTION

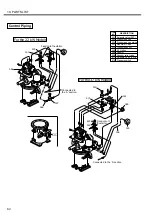

[Models without a built-in air dryer]

[Models with a built-in air dryer]

551

561

663

666

667

687

863

O-ring

Discharge Pipe (2)

Discharge Pipe (1)

Joint, straight

Joint, elbow

O-ring

Socket

ITEM

NO.

DESCRIPTION

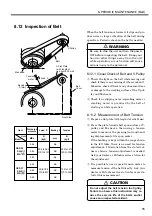

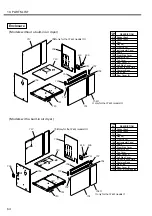

667(22kW)

666(37kW)

663

551

687

561

666

863

667(22kW)

666(37kW)

663

551

687

561