20

4. DAILY CHECK [Lubricant Management]

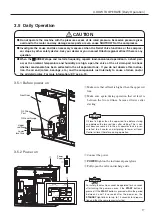

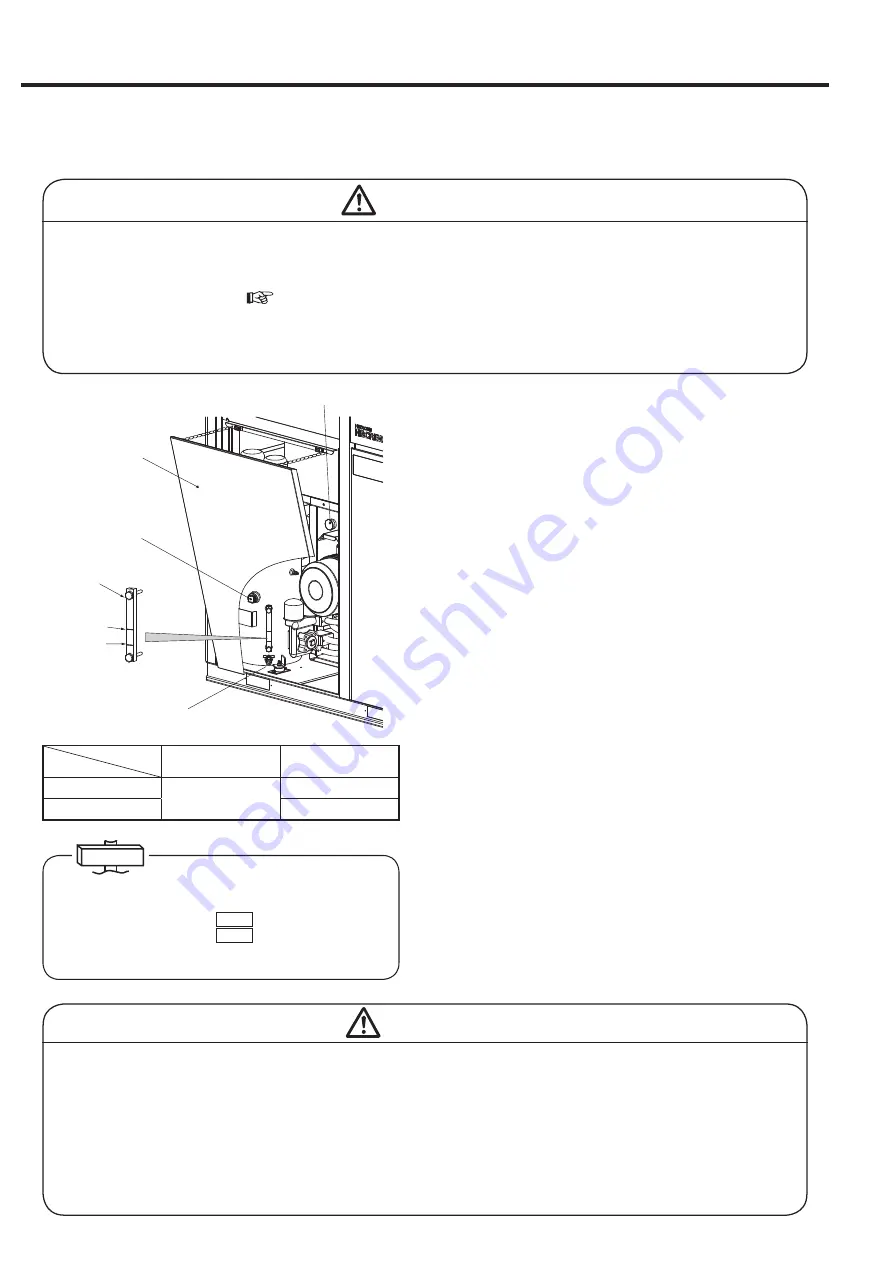

4.3.1 Oil level check

While the compressor is during the load operation,

check the oil level gauge for the amount of the lubri-

cant. When the oil level stays between upper and lower

red lines during the load operation, sufficient lubricant

exists in the system.

If the oil level is above the upper red line, the lubricant

is over filled. In this case, stop the compressor, and

make sure the oil separator tank internal pressure

gauge to check there is no residual pressure in the

compressor, disconnect the power, and drain the lubri-

cant from the oil drain port on the oil separator tank.

If the oil level is below the lower red line, the lubricant

is short. In this case, check the amount to be refilled

while the compressor is during the load operation.

(The distance between the two red lines measures 4

cm. After 0.73 liter of lubricant is added, the oil level is

increased by about 1 cm.) Stop the compressor, make

sure the oil separator tank internal pressure gauge to

check there is no residual pressure in the compressor,

disconnect the power, and refill the lubricant from the

oil filling port.

If the oil level in the shutdown state goes beyond the

upper bolt of the oil level gauge, restart the compressor

and stop it 7 to 8 seconds later. Now, you can check the

oil level in the shutdown state on the oil level gauge.

4.3 Lubricant Management

1

.

When deteriorated lubricant is used without replacement, some of it adhere to the Oil Separator

Element and accumulate heat caused by its oxidization. This may bring even fire in the worst case.

2

.

Change lubricant and Oil Separator Element constantly according to the standard given by the Typical

Maintenance Standard (

see p. 42-44). Deteriorated Lubricant may result fire to the Oil Separator

Element.

3

.

Use genuine synthetic oil (

NEW HISCREW OIL

NEXT

) for lubricant. Avoid use of other brand or mix use

with it.

Oil Separator Tank Internal Pressure Gauge

Oil Separator Tank

Drain Port

Upper Bolt of

Oil Level Gauge

Front Door

Oil Filing

Port

Oil Level Gauge

Upper

red line

Lower

level line

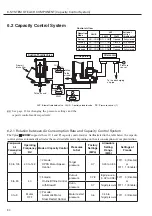

Item

Type

Oil level between

red lines

Oil replacement

quantity

OSP-55VAN

2.9 liters

(

0.73 liters / 1cm

)

26L

OSP-75VAN

36L

WARNING

CAUTION

●

Replenish the oil (genuine synthetic oil) periodically to maintain the proper oil level. Long time opera-

tion without the oil replenishment at low oil level, can cause the shorter oil life or oil deterioration.

●

Oil replenishment shall be carried out every 1,500 to 1,000 operating hours. Replenish amount might

be 1.8L (55kW), 2.4L (75kW) liters. (Actual replenish amount shall be determined by the oil level, as it

is varied by the load rate of the compressor.)

●

Sampling analysis of the oil at every 3000 hours interval is recommended. Earlier oil replacement

might be necessary, depending on the result of the analysis.

Consult HITACHI dealer for the sampling analysis.

Ask your dealer or Hitachi regional office for replacement

of the genuine synthetic oil (

NEW HISCREW OIL

NEXT

).

4 liters oil can: Part No. 063

20 liters oil can: Part No. 064

The genuine synthetic oil may get darkened due to its chem-

ical additives soon after start of use, but it is not abnormal.

IMPORTANT