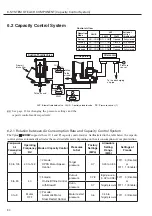

PID stands for Proportional, Integral, and Differential.

CPCS stands for Constant Pressure Control System.

HI

SCREW

Motor

Pressure Sensor

CPCS Motor Speed Control by Inverter and CPU

Inverter

Pressure

P: proportional

I: integral

D: differential

Constant Pressure

of the Discharge Air

Compressed

Air

①

V-mode capacity control (CPCS rotation control method)

By using the pressure signals sent from the pressure sen-

sor, the DCBL controller executes the PID operation to cal-

culate the rotation suitable for the consumption of the com-

pressed air. The DCBL controller outputs the operation fre-

quency command fit for the operation result to the motor.

With keeping the suction throttle valve opened, the dis-

Setting of Cut Out Pressure 1 must meet below requirement.

Cut Out Pressure 1

≧

Target Pressure 1 + (Volume of

Recommended Air reservoir (m

3

))/(Volume of Installed Air

reservoir (m

3

))

×

1/10

<eg>

Volume of Recommended air reservoir: 0.7 m

3

Volume of Installed air reservoir: 1.4 m

3

Target pressure 1 : 0.6MPa

⇨

Cut Out Pressure 1

≧

0.65 MPa

Pressure

Air Consumption

Calculation

Cutout pressure 1

Target pressure

(

=

Cutin pressure)

Motor restart pressure

Time

Time

Hz

>

40

Hz

≦

40

Q

≦

3

%

Operation Frequency Hz

(

Q

≦

30%

)

Q

>

3%

Air Consumption

Q

T

=

1

T

=

0

Number of

Automatic Stop of

Motor in 10 minutes

T

①

②

③

①

②

②

③

③

②

V-mode

Ⅰ

-mode

P-mode

Air Consumption

Q (%)

100

0

②

I

-mode (Online/Offline Control with Blowing-off

of Compressed Air)

The I-mode control is activated (or “integral unload opera-

tion” begins) when:

・

The pressure detected by the pressure sensor rises to a

point of the target pr offline start differential (See

the IMPORTANT below), and at the same time,

・

The operating frequency drops to 40 Hz (equivalent to the

air consumption of 30 %).

As a result the

20P

blowoff solenoid valve and

20US

con-

trol solenoid valve operate to connect the ports NO and

COM. This closes the suction throttle valve and releases

the oil separator tank's internal pressure to the atmosphere.

This is the stating of I-mode capacity control. The motor

idles at its lowest possible speed to save the power con-

sumption while preventing the temperature rise of the

DCBL motor and efficiency drop of the compressor from

occurring.

The I-mode control is deactivated when the pressure detect-

ed by the pressure sensor drops to a point of the target

pressure. The

20P

blowoff solenoid valve and

20US

control

solenoid valve reoperate to connect the ports NC and COM.

This will fully open the suction throttle valve and the

V-mode control (or a loading operation) restarts.

③

P-mode (Automatic Motor Stop/Restart Control)

The P-mode control is activated when:

・

The calculated air consumption decreases to 3 %, or

・

The I-mode control continues for 3 minutes.

As a result the motor automatically stops. For protection,

the motor can stop only at 10-minute intervals.

The P-mode control is deactivated when the pressure

detected by the pressure sensor drops to a setting point of

the motor restart pressure.

(1) The motor, once stopped, cannot restart for 60 seconds

after that.

(2) The plant airline pressure may drastically drop before

the motor will restart 60 seconds later. To prevent this

pressure drop, install the air receiver tank whose capaci-

ty is no less than 0.7m

3

for 55kW and no less than

1.24m

3

for 75kW.

charge air pressure can be still controlled within a range

thanks to increasing or decreasing the motor speed itself.

IMPORTANT

IMPORTANT

31

6. SYSTEM OF EACH COMPONENT [Capacity Control System]

IMPORTANT