Only pulse signal of 0.5 second or more for Start/Stop sig-

nal can actually control the compressor at remote opera-

tion.

If such signal from remote place is a level signal (make

contact), following failures can happen:

(1) The unit automatically starts operation by setting the

remote operation switch if start/stop is not canceled.

(Operation by other than intentional action.)

(2) When shutdown happens, the unit will start again by

pressing the

RESET

button on the instrument panel if

the operation signal by remote control is not canceled.

(3) Even though remote control for starting the unit is tried

at the site, the unit can not start without operation sig-

nal at REMOTE given. (No independent operative

manipulation cannot be achieved at the site.)

(4) Despite the stop operation at the site, the unit does not

stop if REMOTE operation and stop signal are not can-

celled.

(The unit stops while pressing the

STOP

button, and

starts again when the button is released.)

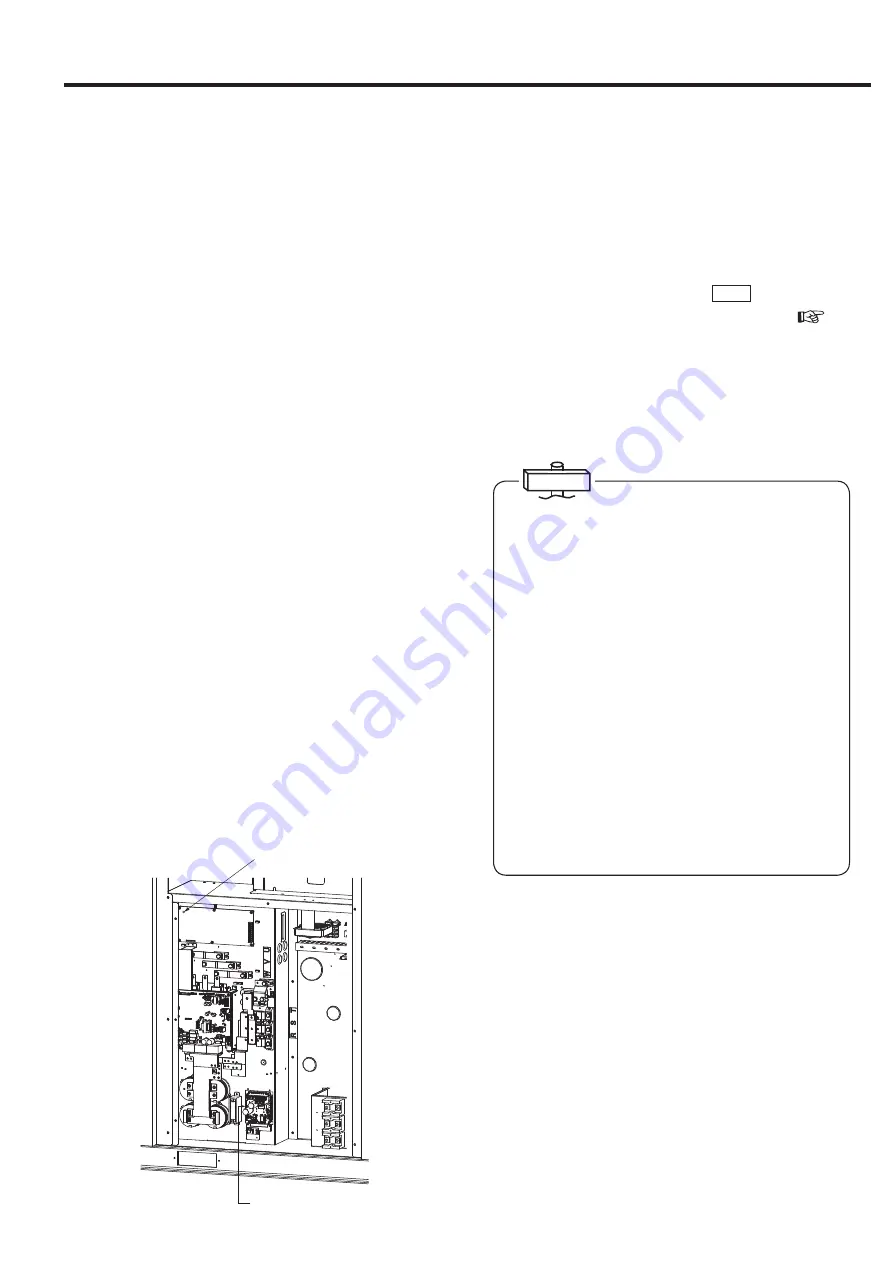

7.6.6 In case of Remote Operation

In case the compressor is controlled for its start and

stop by the remote operation, it is required to connect

signal lines from remote place to the terminal board

inside the starter panel. See the figure “TB-1 terminal

part” in the wiring diagram in pages 40 through 41.

If fixing the setting to remote, set F005 .

For further information on a remote operation,

see

p. 16.

One dry contact for each of operation and shutdown is

prepared at the “a (normal open)” contact. Rated cur-

rent is AC250V 0.5A.

IMPORTANT

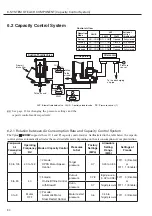

(5) When you check the performance of the capacity

control system in an initial startup operation, setup

the blow-off stop valve that is mounted at the sec-

ondary part of the air receiver tank. If you have to

use the alternative stop valve at the discharge outlet

of the

HISCREW

, close it slowly and gently.

Closing it violently may cause the relief valve to

operate or release the internal pressure. (This is not

abnormal because the motor speed control system

delays responding to a sudden change in pressure.)

When the multiple

HISCREW

s are operated in par-

allel, they control a capacity independently from

each other. Before proceeding to perform an initial

star tup operation, therefore, you must know a

capacity control feature that varies depending on

the type of

HISCREW

, and adjust the pressure set-

tings of each unit so that the

HISCREW

s can load

and unload in a scheduled order.

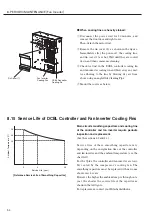

(6) The DCBL controller performs a quick switching

action that causes the input side to produce a har-

monic distortion and the output side to produce a

high-frequency noise and a leakage current.

The Vplus

HISCREW

contains a DC reactor to sup-

p r e s s a h a r m o n i c d i s t o r t i o n . I t f e a t u r e s a

shortlength wire to the motor and is shielded by

the enclosure panels, which makes a highfrequency

noise and a leakage current affect negligibly.

Depending on the stray capacitance of the power

cord, however, the earth leakage relays and/or cir-

cuit breakers may malfunction. Therefore, use the

necessary noise filters etc. that support the inverter.

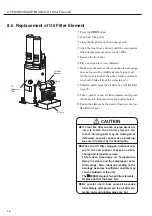

Charge Lamp(Fan inverter)

(Make sure that it is off)

Charge Lamp(Controller)

(Make sure that it is off)

39

7. INSTRUCTIONS FOR INSTALLATION [Instructions on Electrical Wiring]