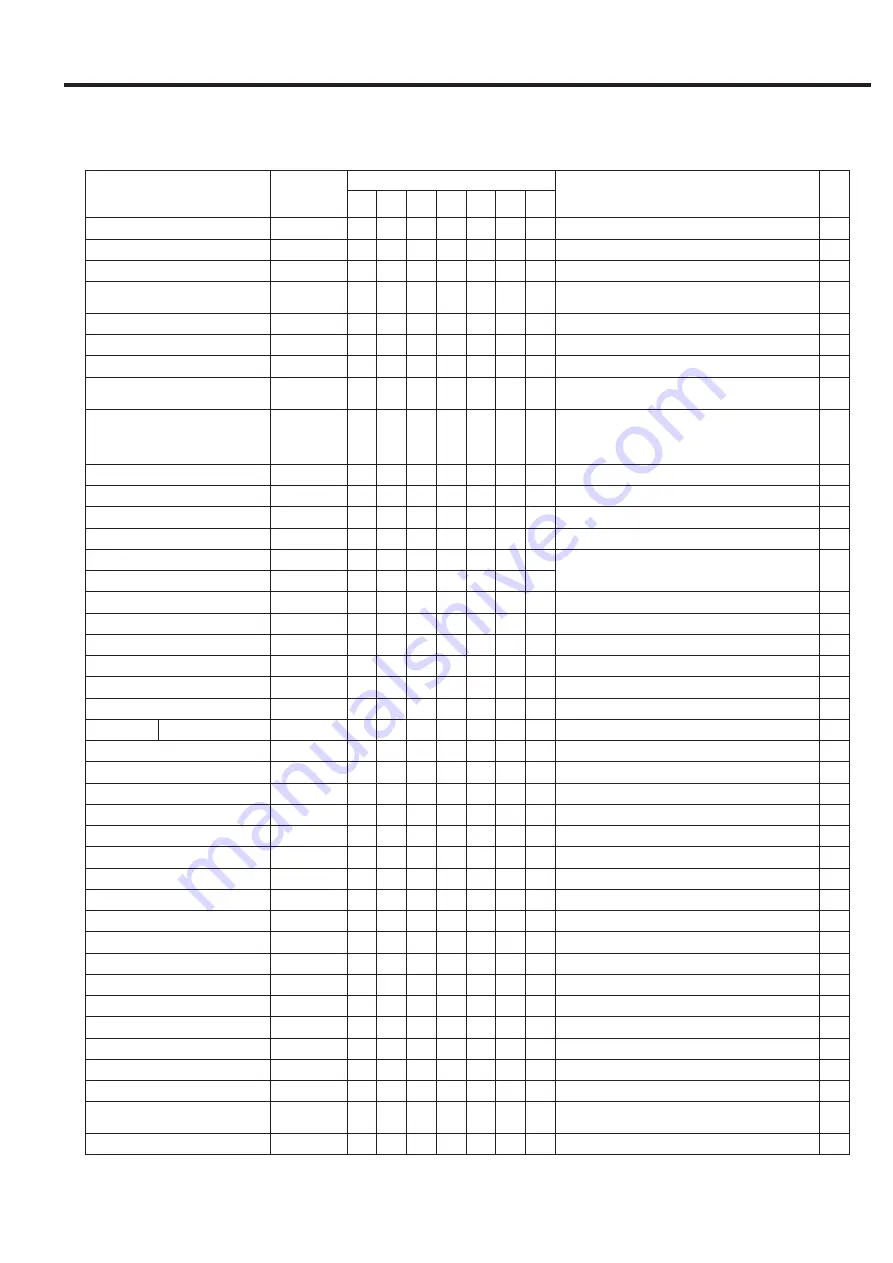

8.2 Typical Maintenance Standard (A) of Air Compressor

…

In case of annual run hour less than 6,000 hours

Maintenance part and item

Check

Inspection time

Note

Reference

page No.

Daily 1-Month 6-Month 1-Year 2-Year 4-Year 8-Year

Oil level gauge

Oil level check

○

Oil level must be within red lines during operation.

20

Discharge air temp.

Discharge air temp. check

○

Must be between 65

℃

and 100

℃

.

18

Relief valve

Performance check

○

Check by hand.

45

Lubricant (genuine synthetic oil)

Replenish/

Analysis

(○)

Replenish every 1,000 to 1,500 hours

Sampling analysis every 3,000 hours

20,21

Motor

Greasing

○

Use “RMS Grease”

52

Motor's cooling fin

Cleaning

○

52

Grease Reservoir

Cleaning

○

Clean once for every 2 grease replenishments.

52

Mechanical seal

Oil leak check

○

If the oil leak is 3 cc/h or higher, replace the seal even

before 8-year (48,000 hours) operation.

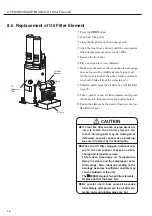

Air intake filter element

Replacement

○

Clean if the error code of an element clogging

appears on the digital monitor. Replace whenev-

er the number of times of cleaning has reached

5 times even within one year interval.

47

Oil filter element

Replacement

●

46

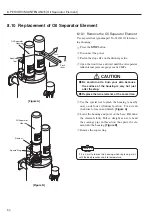

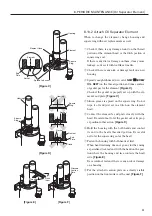

Oil separator element

Replacement

●

Replace the housing and square ring as well.

50

Solenoid valve

Performance check

●

Cooling fans

Crack check/Cleaning

●

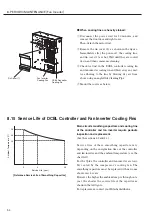

DCBL controller cooling fan

Crack check/Cleaning

●

Clean cooling fins and duct.

53

Fan inverter

Crack check/Cleaning

●

Motor

Insulation check

●

1M ohm or more at DC500 V Mega.

Electric panel, instruments, sensors

Inspection/Cleaning

●

Terminal refastening, electric line cover check and cleaning.

Pipe joints

Loose check

●

Oil cooler, Aftercooler

Cleaning

●

Lubricant (genuine synthetic oil)

Replacement

○

21

Oil level gauge

Replacement

●

Consumable Parts Suction throttle valve

※

Replacement

●

Replace the cap seal, valve plate, and O-ring.Clean.

Piston of minimum pressure valve / check valve

※

Replacement

●

Replace check valve spring, O-ring at the same time.

49

Oil filling port O-ring, plug O-ring

Replacement

●

Suction pipe

Replacement

●

Oil temperature control valve

Inspection/Cleaning

●

Change O-ring.

DCBL controller cooling fan

Replacement

●

Including cooling fan in the starter/control box.

Fan motor bearing

Replacement

●

If not so, clean it and continue to use it.

Thermistor

Inspection

●

Oil temperature control valve

Replacement

●

Check valve (1/4 inch)

Replacement

●

Locate it on the oil-scavenging pipe from the shaft seal.

Coupling elastic body

Replacement

●

If not so, clean it and continue to use it.

O-ring (Air end)

Replacement

●

O-ring (Flange)

Replacement

●

O-ring, oil separator tank O-ring

Replacement

●

Replace 1/2 stop valve O-ring at the same time.

DCBL motor bearing

Replacement

●

Mechanical seal

Replacement

●

Compressor Air end bearing

Replacement

●

Controller smoothing capacitor

Replacement

●

CPU printed circuit board,

power PCB

Check/Clean/Replace

●

If it is dirty or shows a change in color, replace it.

If not so, clean it and continue to use it.

Fan inverter

Replacement

●

※

Replace these parts every 2 calendar years or when the

HISCREW

has loaded/unloaded total 1,000,000 times,

whichever comes earlier. For the total load/unload times, watch the digital monitor.

43

8. PERIODIC MAINTENANCE [Maintenance Standards (A)]