45

8. PERIODIC MAINTENANCE [Relief Valve, Capacity Control System]

8.5

Performance Check of

Capacity Control System

①

Gradually close the stop valve on discharge side

(located after the air receiver tank) to raise the dis-

charge air pressure. When the discharge air pres-

sure rises to the target pressure whatever you have

set, the inverter operates and starts dropping the

motor’s operating frequency.

②

Immediately when the motor's operating frequency

drops to 40 Hz, fully close the stop valve.

③

The suction throttle valve works and releases the

compressed air in the oil separator tank to the

atmosphere. Using the oil separator tank internal

pressure gauge, check the pressure in the oil sepa-

rator tank is stabilized at or below 0.15 MPa.

④

Fully open the stop valve on discharge side within 3

minutes after the I-mode capacity control is activat-

ed. Make sure that the air end reloads accordingly.

・

If the air receiver tank capacity on the discharge side is

less than recommended capacity, the air end reloads

before the pressure in the oil separator tank becomes

stable pressure.

・

Do not operate the stop valve immediately after stop-

ping the

HISCREW

. Otherwise the motor’s operating fre-

quency may fluctuate and/or the relief valve may oper-

ate.

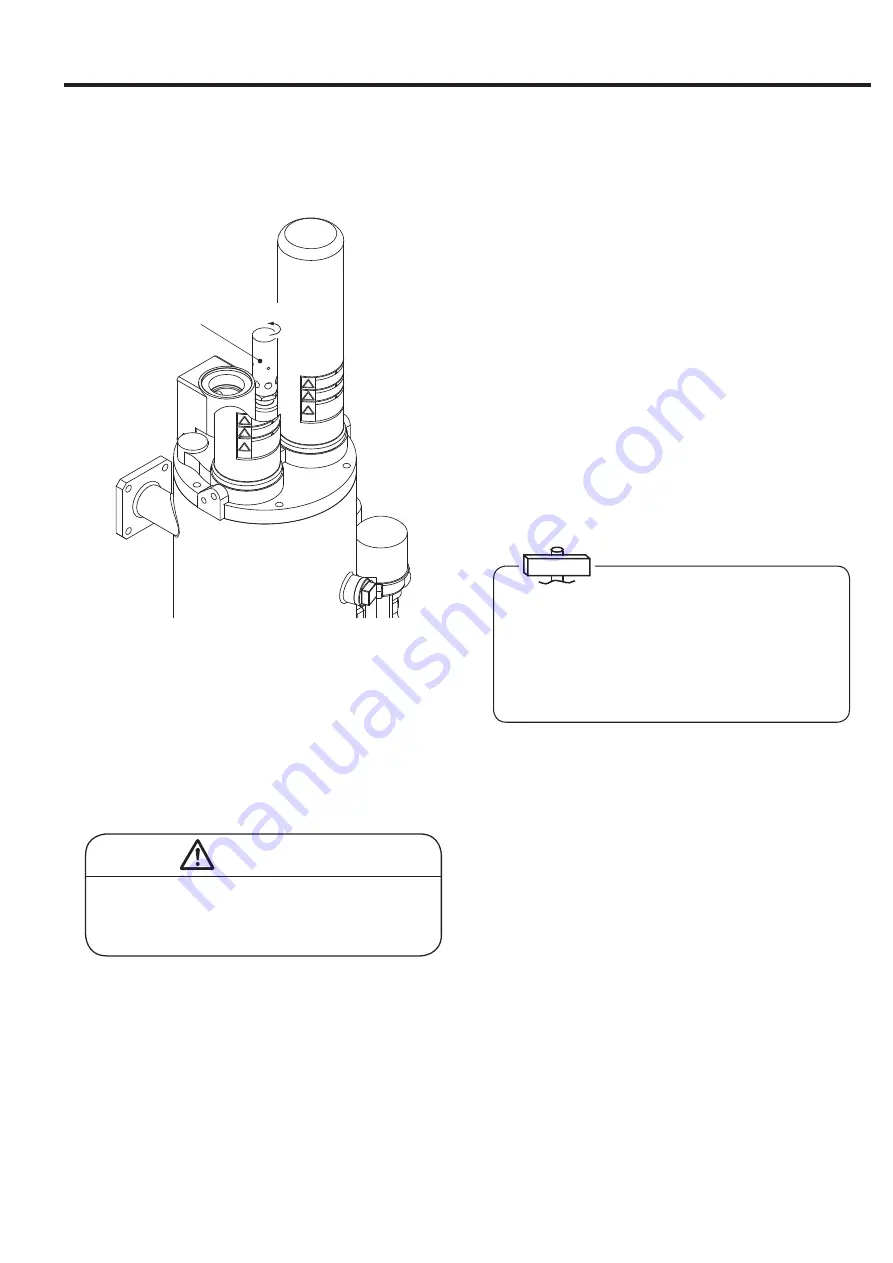

8.4

Performance Check of

Relief Valve

Relief Valve

Open

①

Set Discharge air Pressure to 0.7MPa.

②

Open the front door and turn the cup of the relief

valve anti-clock wise.

③

If the compressed air comes out, turn the cup of the

relief valve clock wise.

IMPORTANT

WARNING

Do not place your face near Relief Valve when

to check its performance. Compressed air can

come out and it is dangerous.