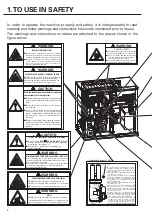

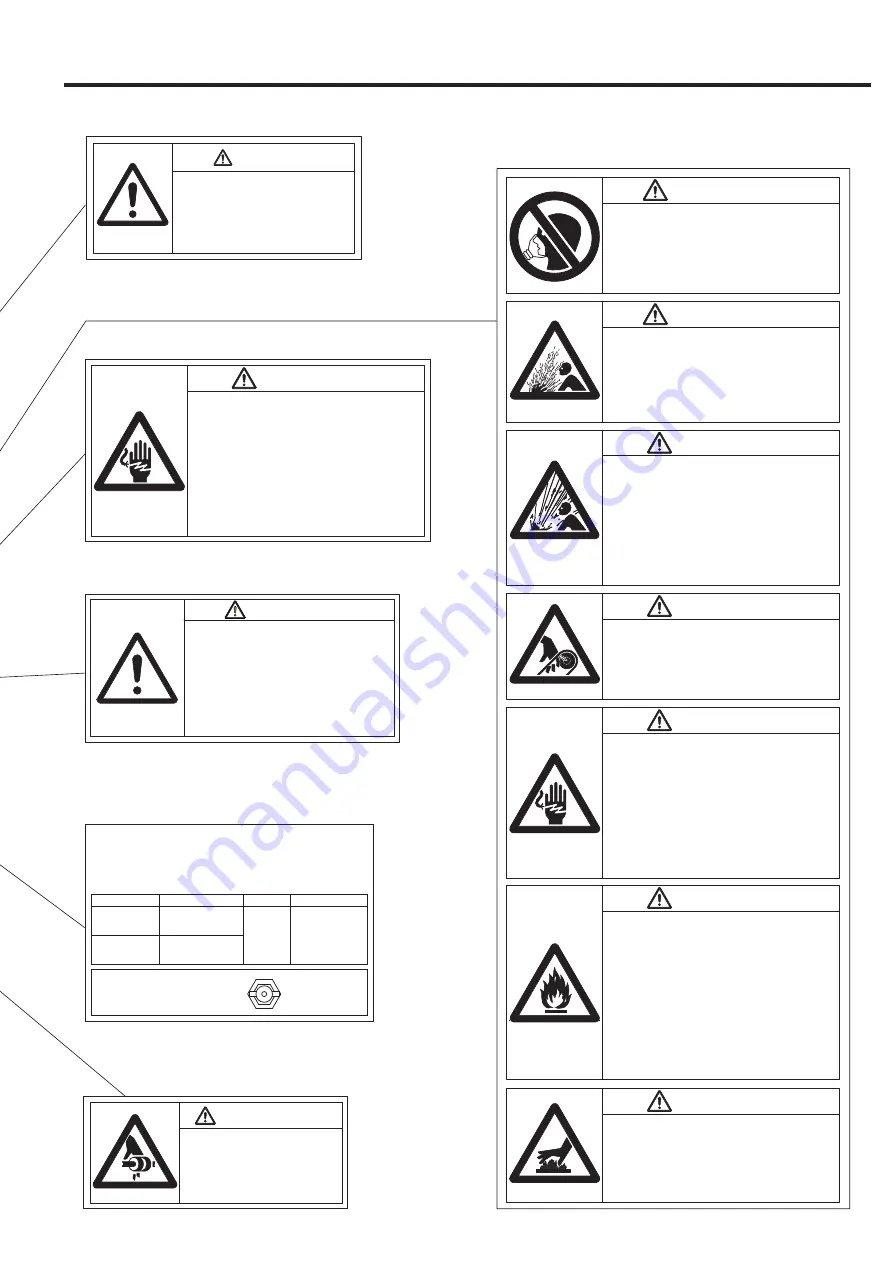

ROTATING PARTS!

WARNING

DO NOT touch the rotating parts such

as coupling with hand or bar.

When the unit is running AUTO mode,

the machine will start without

pressing the start button.

WARNING

AIR INLET PORT!

Keep your hands and any

objects away from the air

inlet port of suction

filter.

STRONG MAGNETISM

WARNING

Pay high attention for handling the motor because

it has a quite strong permanent magnet rotor in

the housing.

Those who has electronic medical devices such as

pace makers must be away from the magnetic

rotor.

Do not put electronic devices such as magnetic

cards, watches and measuring equipments closer

to the magnetic rotors.

For disassembly, please contact HITACHI

authorized distributors near you.

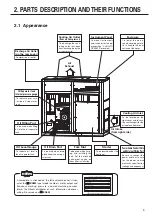

Operating condition

Filling interval

Filling amount

Main motor grease replenishment

Fill a specified amount of grease periodically at the [grease filling

ports]located at the load side.

Be aware that grease replenish over the defined amount may

cause overheated bearing, grease leakage,etc.Replenish grease

while the compressor is running.

When operating more

than 3000hr/year

When operating

3000hr/year or less

75g

Grease

Every 6 months or 3000 hours,

whichever comes first

Every 1 year or 3000 hours,

whichever comes first

[Load side grease filling port]

Rare max super N

KYOUDO YUSHI Co.,LTD

Iten No.: 59031350

DO NOT BREATHE AIR!

HIGH-TEMPERATURE AND HIGH-PRESSURE OIL AND AIR

ELECTRIC SHOCK HAZARD!

CAUTION

CAUTION

HOT!

WARNING

WARNING

WARNING

WARNING

FLAMMABLES!

ROTATING PARTS!

WARNING

FIRE!

●

DO NOT use the discharged air for a direct-breath

application. Discharge air contains oil particles.

Breathing the air can cause the respiratory

distress and serious injuries.

●

It is also dangerous to operate the air compressor

in badly ventilated rooms, tunnels and so on.

Before replacing the oil or servicing the compressor,

stop its operation, disconnect the power, and make

sure that the discharge air pressure gauge indicates

0(zero)MPa, completely. In case that residual

pressure is in components,high-temperature oil and

air spout out,and can cause serious burns or injuries.

●

Keep your hands and any objects away from the

rotating parts (pulleys, belts, cooling fans, etc.).

●

Be careful of the stopped air compressor in an

automatic stop/restart control because it may

restart without pressing the START button.

●

Before servicing or wiring the air compressor, dis-

connect the power and wait for about 10 minutes

that electric charge of the inverter is completely

discharged. This will prevent anyone from turning

on the power and causing an electric shock that

can lead to serious injuries.

●

DO NOT allow any unlicensed person to wire the

air compressor. Always ask to work a licensed

electrician.

●

Ground the air compressor.

●

DO NOT use fire around the air compressor. The

sparks from the fire may cause internal burnout

of the air compressor.

●

DO NOT dismantle any protective relays on the

air compressor. Also, DO NOT modify the control

circuit to prevent its protective function. In case

that improper modification is done, it can be

c a u s e s w h y t h e c o m p r e s s o r b u r n s o u t o r

catches a fire.

●

Install an earth leakage fuse free breaker on the

power supply.

●

Check the oil level on the oil gauge that it is

between the red lines of upper and lower.

●

DO NOT touch the air compressor during it is

running or immediately after it has stopped,

because its components are quite hot.

●

Keep your hands/face away from the exhaust port

from cooling fan, because high-temperature air is

exhausted from this port.

ELECTRIC SHOCK HAZARD!

WARNING

●

Before servicing or wiring the air compressor, dis-

connect the power and wait for about 10 minutes

that electric charge of the inverter is completely

discharged. This will prevent anyone from turning

on the power and causing an electric shock that

can lead to serious injuries.

●

DO NOT allow any unlicensed person to wire the

air compressor. Always ask to work a licensed

electrician.

●

Ground the air compressor.

HI

●

Keep a container of the flammable hazards

(solvents etc.) away from the air compressor. It

can cause explosion.

●

DO NOT use any brand’s oil then “

NEW HISCREW

OIL

NEXT

” (Hitachi's genuine synthetic oil).

Replace the oil and the oil separator(element and

housing) periodically as the instruction manual.

Any defect of oil separator and oil degradation can

cause explosion or fire.

3

1. TO USE IN SAFETY