Summary of Contents for L Series

Page 2: ......

Page 12: ... 8 3 3 Connection diagram 1 L type single speed wiring diagram ...

Page 13: ... 9 2 LN type dual speed wiring diagram ...

Page 14: ... 10 3 LS type single phase wiring diagram ...

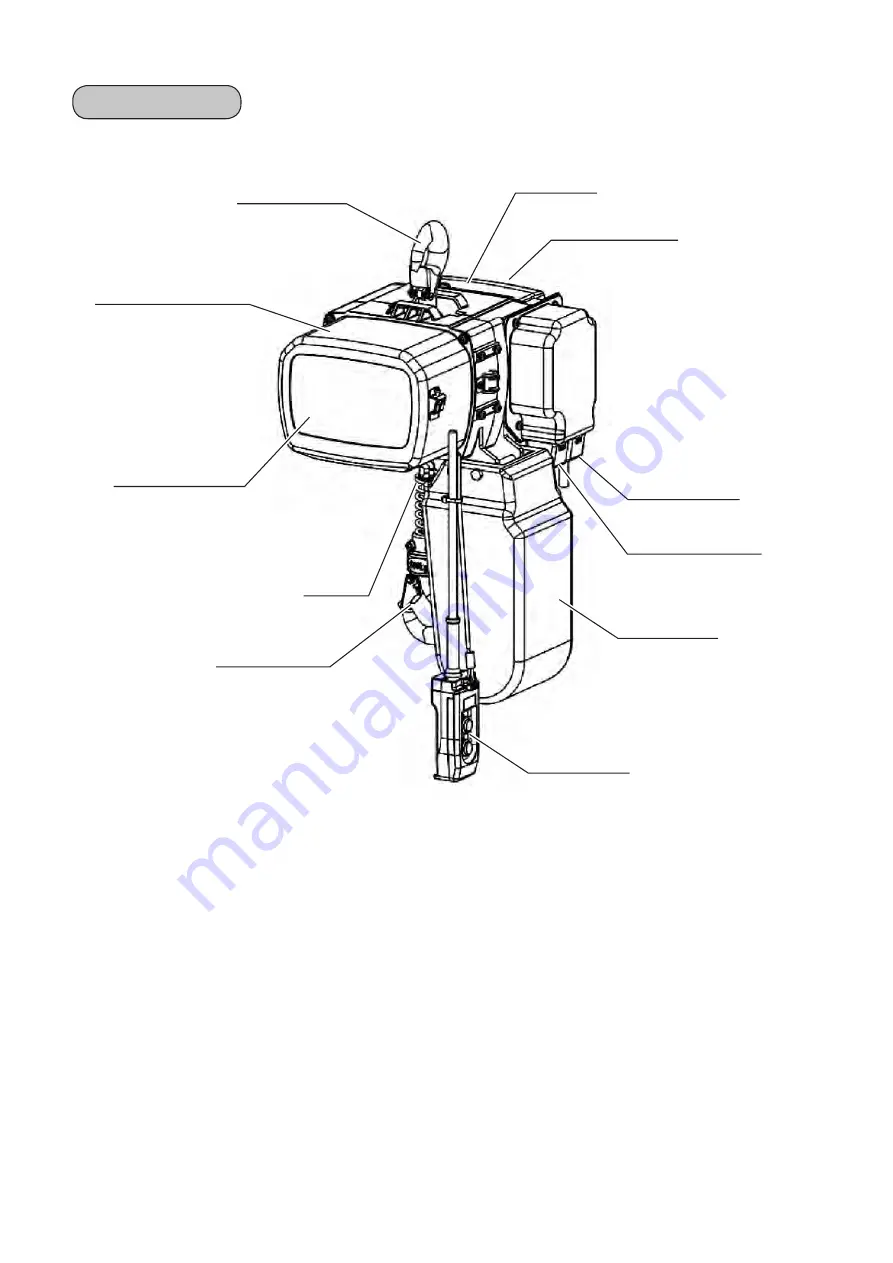

Page 34: ... 30 Bill of material of L type ...

Page 35: ... 31 Bill of material of LN type ...

Page 36: ... 32 Bill of material of LS type ...

Page 42: ...MEMO ...

Page 43: ...MEMO ...

Page 44: ...3 Q3975 2C ...