--- 9 ---

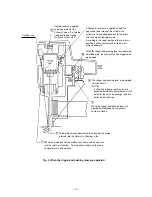

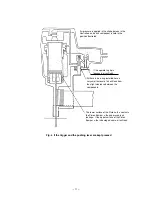

8-2. Operation Principle

The operation of the Model N 5008AC is illustrated and described in Fig. 4 through 7. The circled numbers in the

descriptions correspond to the item numbers shown in the mechanism illustrated in Fig. 3. In Fig. 5 and Fig. 7,

read the descriptions in alphabetical order.

Fig. 4 When the compressed air source (air hose) is connected to the nailer

Air pressure is applied to the lower surface of the flanges

located at the center portion of the Cylinder < 6 >, forcing

the cylinder upward. The compressed air is thereby

blocked from the upper end of the cylinder, and no pressure

is applied to the piston.

The Accumlator < 1 > fills with

compressed air.

The trigger and pushing lever are not

operated, and remain closed.

The exhaust vents are opened and no air pressure is

applied to the valve air passage.

Summary of Contents for N 5008AC

Page 33: ......