9

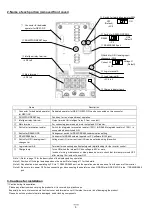

(2) Control terminal description

Category

Symbol

Name

Description

Electrical characteristics

Power

supply

L

Common for input signals

Common for internal control power supply, digital

inputs/outputs, analog inputs/outputs

H

Power supply for external

potentiometer

DC10V power supply. Used with variable resistor for O

input.

Max.10mA withdraw

A

n

a

lo

g

Freq.

set

O/OI

Analog voltage

(Use SW6 for selection)

Frequency set via DC0~10V input

Input impedance=apprx.10k

Ω

Allowable range;

-0.3~+12VDC

Analog current

(Use SW6 for selection)

Frequency set via 0~20mA

Parameter adjustment should be done in case of 4~20mA

Input impedance=apprx.250

Ω

Allowable range;

0~24mA

D

ig

ita

l

Power

supply

L

Common of digital and analog

Inputs

Common for internal control power supply, digital inputs,

analog inputs/outputs

P24

Power supply for digital inputs

DC24V power supply for dry contact input. (Common

terminal in case of source logic)

Max.100mA output

PLC

Power supply terminal

for input terminals

Sink logic : connected to P24

Source logic : connected to L

Remove the jumper wire when using external power supply

for controlling the dry contact inputs (Refer to “QRG”5.7)

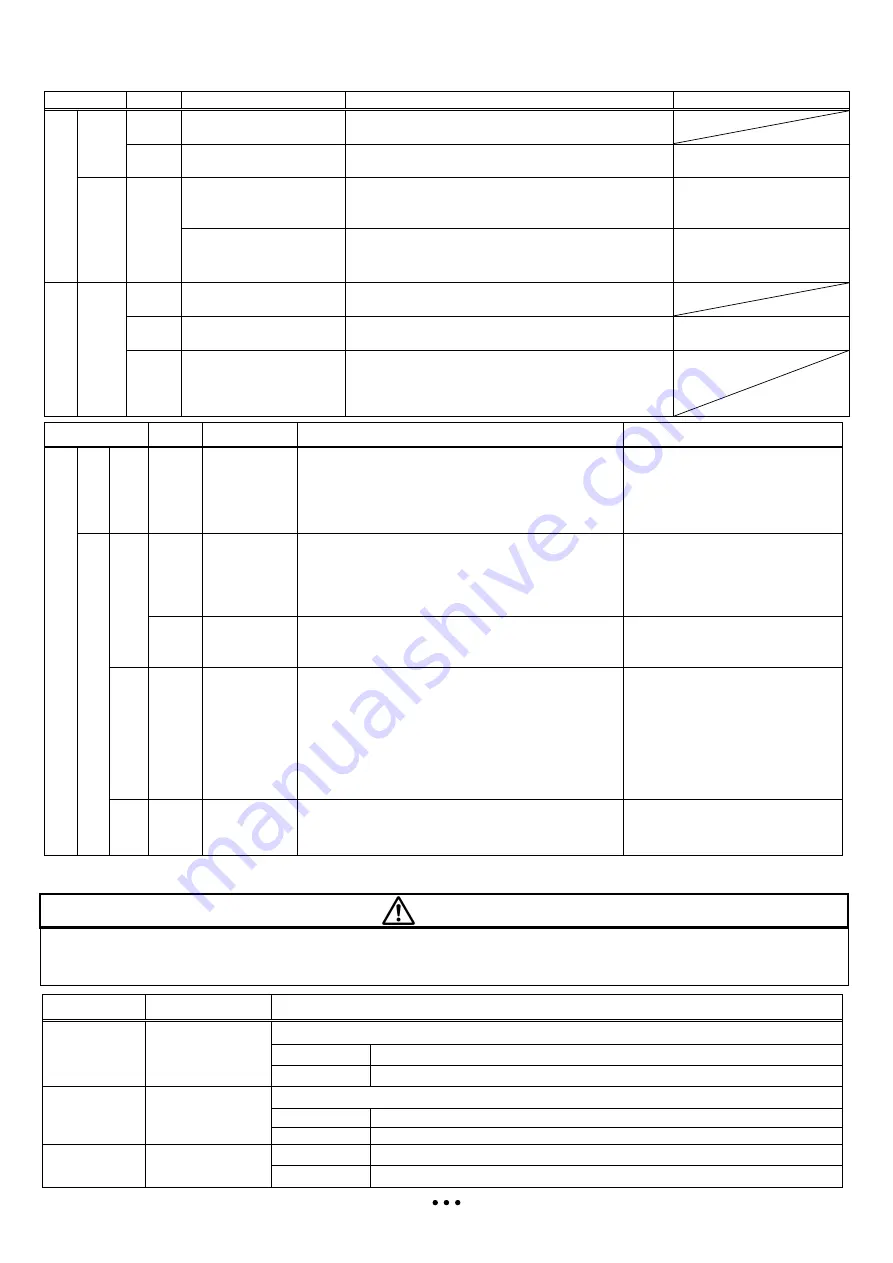

Category

Symbol

Name

Description

Electrical characteristics

D

ig

ita

l

In

p

u

t

C

o

n

ta

c

t

5

4

3

2

1

Intelligent input

terminals

Select 5 functions from 35 available functions when can be

assigned to any terminal 1 to 5. Sink or source logic can

be selected. Refer to section 7.3 of “QRG” for the details

Voltage between each input and PLC

- V(ON) = min.18V

- V(OFF) = MAX.3V

- Max. allowable voltage = 27VDC

- Load current 5mA (24V)

O

u

tp

u

t

O

p

e

n

-c

o

lle

c

to

r

11

Intelligent

output

terminals

One function from 28 available functions can be assigned.

Refer to section 7.3 of “QRG” for the details

Open collector output

Between 11 and CM2

- Voltage drop during ON=4V or less

- Max. allowable voltage = 27V

- Max allowable current = 50mA

CM2

Common for

intelligent output

terminals

Common for the terminal 11.

Max. allowable current = 100mA

R

e

la

y

AL0

AL1

AL2

Intelligent relay

outputs

One function from 28 available functions can be assigned.

(1-c contact)

Refer to section 7.3 of “QRG” for the details.

Max. contact capacity

AL1-AL0 : AC250V,

2A(resistive),0.2A(inductive)

AL2-AL0 : AC250V,

1A(resistive),0.2A(inductive)

Min. contact capacity

AC100V, 10mA

DC5V, 100mA

P

u

ls

e

tr

a

in

FM

Digital pulse

train output

(PTO) Pulse frequency maximum is 3.6kHz

Pulse voltage : DC0/10V output

Max. allowable current : 2mA

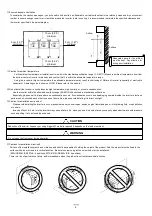

(3) Changeover switch description

Refer to page 5 for the location of the switches.

Symbol

Name

Description

SW4

Termination resistor

selection switch

Select able/disable of the termination resistor of RS485 port (RJ45)

OFF (left side)

Termination resistor (100

Ω

)

Disable (Default)

ON (right side)

Termination resistor (100

Ω

)

Able

SW5

RS485/OPE(RS422)

selection switch

Select depending on the options and communication method, connected to RS422/RS485 port.

OFF(right side) For operator (OPE-S/SR/SBK/SRmini),ProDriveNext (Default)

ON(left side)

For RS485 communication (Modbus-RTU)

SW6

Analog input (O/OI)

selection switch

OFF (left side)

Current input (0~20mA) OI

ON (right side)

Voltage input (0~10Vdc) O (Default)

- Adjustment of the switch must be done during power off. Otherwise there is a risk of electric shock.

- Power ON must be done after closing the front cover. Do not open the front cover during power up, or when there is a remaining voltage.

There is a risk of electric shock.

CAUTION

CAUTION

CAUTION

CAUTION