-25-

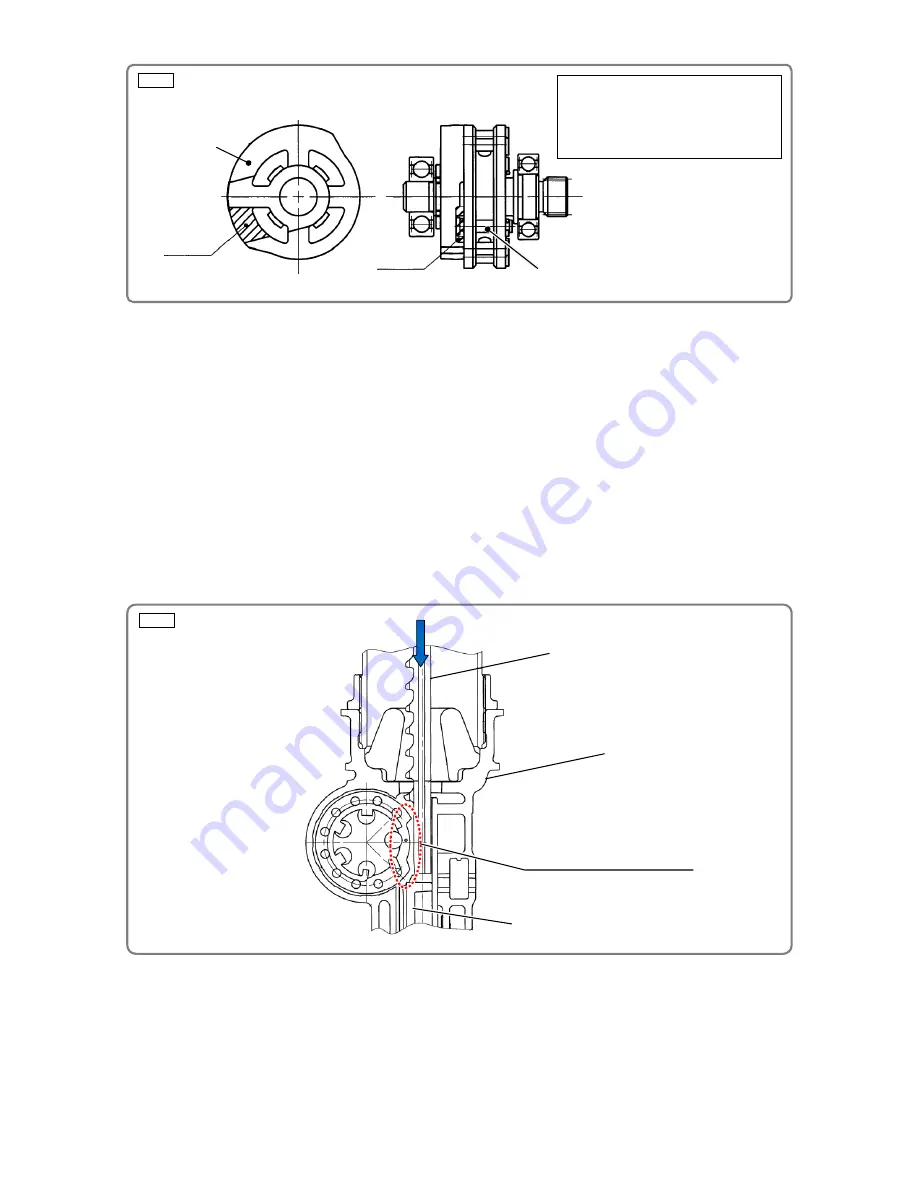

Fig. 30

Fig. 31

• Remove dust from between the Pin Wheel

[27](27)

and Needle Roller D3

[30](30)

and apply about 1.5 g

of Molub-Alloy 777-1 grease to the Needle Roller D3

[30](30)

, eight Needle Rollers D4

[32](32)

, and

Needle Roller D4.5

[26](26)

evenly.

• Apply about 0.2 g of Isoflex Topas NB52 grease to the two Slide Rings

[13](13)

included in the brand-new

Piston Ass'y

[15](15)

evenly. Then mount the two Slide Rings

[13](13)

to the Piston Ass'y

[15](15)

.

• Apply about 1.0 g of Isoflex Topas NB52 grease to the X-ring

[14](14)

included in the brand-new Piston

Ass'y

[15](15)

evenly. Then mount the X-ring

[14](14)

to the Piston Ass'y

[15](15)

.

• Put the Pin Wheel

[27](27)

in the Nose

[17](17)

. Facing the notch of the Pin Wheel

[27](27)

to Blade

Guide (A)

[70](70)

, push the Piston Ass'y

[15](15)

down to the bottom dead point without meshing with

the eight Needle Rollers D4

[32](32)

and Needle Roller D4.5

[26](26)

as shown in Fig. 31. Apply about

1.5 g of Isoflex Topas NB52 grease to the inside of the Cylinder

[5](5)

evenly.

NOTE: If the Position Detector [25](25) is not precisely located, an error (causing the orange LED

of the battery indicator to blink) may occur.

• Slowly tighten the four Nylock Bolts M6

[11](11)

to fasten the Chamber Base

[10](10)

and Chamber Cover

[4](4)

. Be careful not to pinch and damage the O-ring (I.D 94.5)

[7](7)

.

• Perform reassembly of the power assembly according to pages 16 to 20.

Pay special attention to the position of

the Position Detector

[25](25)

.

If the Position Detector

[25](25)

is

misaligned, the standby position of the

piston is also misaligned. (See page 29.)

[27](27)

[25](25)

Notch

Notch

Notch of the Pin Wheel

[27](27)

[15](15)

[17](17)

[70](70)