--- 23 ---

Use specified nails.

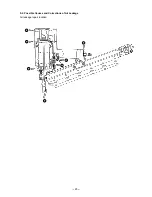

See <Magazine> in item 1).

Replace the part.

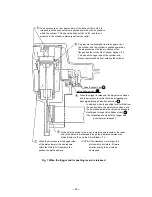

See <Output section> in

item 1.)

Check if the nails are

specified ones.

Check if they move

smoothly after putting nails,

and check if the nail feeder

operates smoothly.

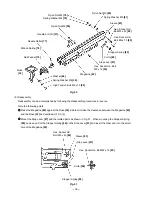

Check if the driver blade tip

is worn.

Perform idle driving or

actually drive with nails, and

check if the driver blade has

returned completely.

Adjuster is improperly

adjusted.

Air pressure is too low.

Workpiece is very hard.

Driver blade is worn.

Piston ring is abnormal

(worn or damaged).

Cylinder's internal surface is

abnormal (worn or rough).

Unspecified nails used.

<Improper nail feed>

See <Magazine> in item 1).

Driver blade worn.

<The driver blade has not

returned completely.>

See <Output section> in

item 1).

For short nails, the adjuster

is raised too high.

Nails are not fully fed into

the injection port.

Unspecified nails are used.

Driver blade is worn.

Workpiece is very hard.

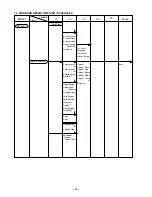

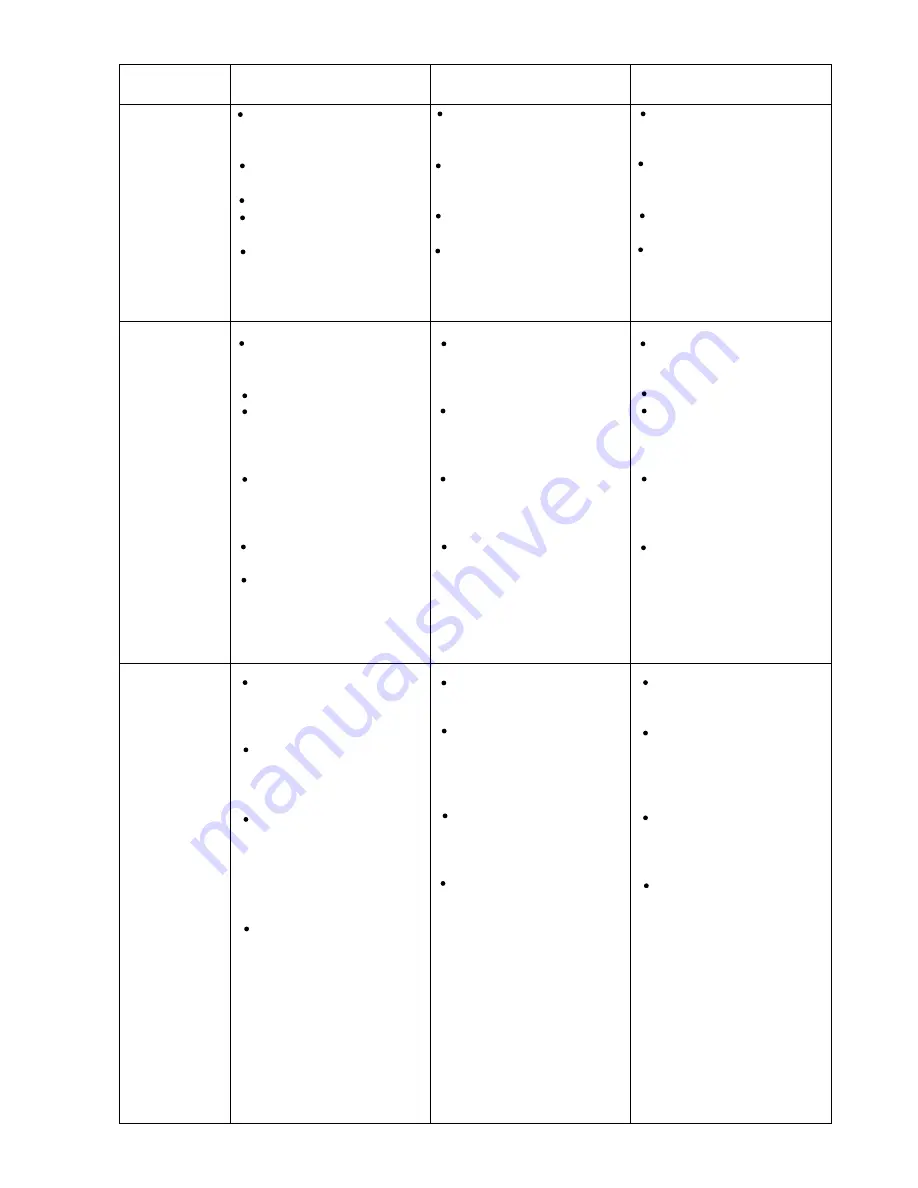

Problem

Possible cause

Inspection method

Remedy

2) Nails are bent

when being

driven.

Check if the adjuster is

raised too high.

See item 1).

Check if the driver blade tip

is abnormally worn.

Drive a nail into soft wood

workpiece and check if the

nail is bent.

Turn the adjuster to the

lower position to decrease

the pressure.

See item 1).

Replace the driver blade.

Do not use unspecified

workpieces.

3) Head of a nail

driven into a

workpiece

protrudes

from the wood

surface.

Turn the adjuster to the

lowest position and drive a

nail.

Drive a nail into soft wood

workpiece and check if the

head protrudes from the

wood surface.

Operate the nailer without

nails and check if the driver

blade is projected from the

nose tip.

Disassemble the output

section and check the piston

ring, O-ring and the inner/

outer surfaces of the

cylinder for abnormal

condition.

4) Nails clog the

mechanism.

Adjust the adjuster to the

proper position.

Adjust for 5 to 8.5 kgf/cm

2

.

Do not use unspecified

workpieces.

Replace the driver blade.

Replace the defective part.

Summary of Contents for NR 83A2

Page 46: ......