--- 22 ---

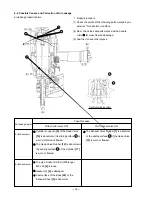

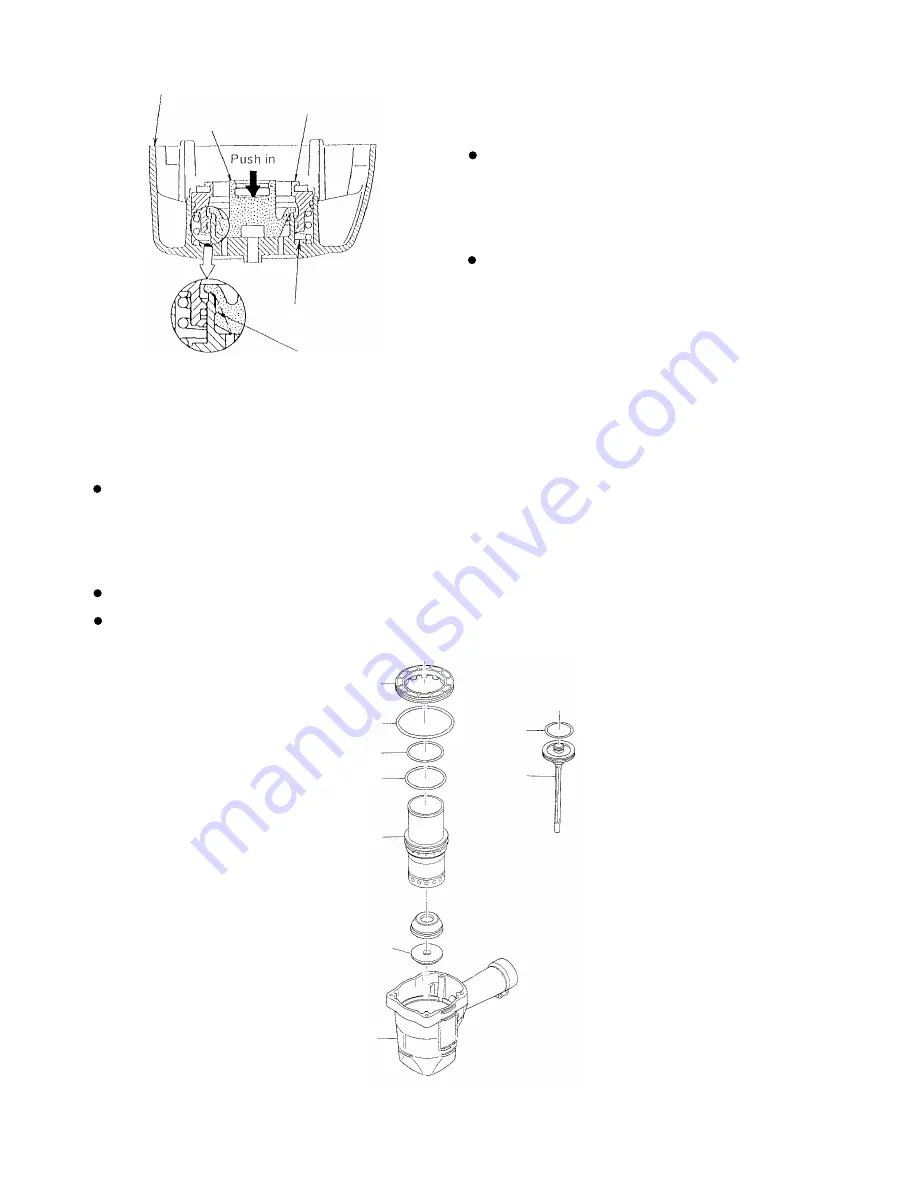

Fig. 12

Cylinder [17]

Body [22]

Cylinder Plate [13]

(b) Reassembly

Disassembly procedures should be followed in the

reverse order. Note the following points.

Charge the sliding portion of the Head Valve [10]

of the Exhaust Cover [5] with about 3 grams of

grease and apply grease to each surface of the

O-rings.

As shown in Fig. 12, firmly push the Exhaust Valve

Rubber [7] until it is fully seated over the

projection of the Exhaust Cover [5].

Exhaust Cover [5]

Charge with grease of 3 grams.

Head Valve [10]

Exhaust Valve

Rubber [7]

Push until the rubber is fully

seated over the projection.

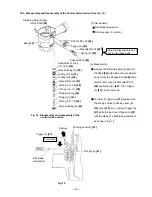

(2) Disassembly and reassembly of the Cylinder [17], Piston [19], Piston Bumpers (A), (B) [24], [25], etc.

(See Fig. 13.)

(a) Disassembly

Remove the Exhaust Cover [5] as described in item (1). Now, the Cylinder [17], Cylinder Plate [13], Piston

[19], Piston Bumpers (A), (B) [24], [25], etc. can be taken out.

(b) Reassembly

Disassembly procedures should be followed in the reverse order. Note the following points.

Apply designated grease to the O-ring (1AP-48) [18] and the internal side of the Cylinder [17].

Apply designated grease to the O-ring (S-95) [14], O-ring (I.D 59.6/W2.4) [15] and the O-ring [16], and then

install them.

Fig. 13 Disassembly and reassembly of the cylinder, piston, piston bumper, etc.

Piston Bumper (A) [24]

O-ring (S-95) [14]

O-ring (I.D. 59.6/W2.4) [15]

O-ring [16]

Piston Bumper (B) [25]

O-ring

(1AP-48)

[18]

Piston

[19]

Summary of Contents for NR 90AC3

Page 39: ......