English

15

3

Release the lock lever and open guide plate (See

Fig.

28

).

4

Remove the jammed nail with a slotted-head

screwdriver (See

Fig. 29

).

5

Close guide plate and latch.

NOTE

In case of frequent jams, consult the Authorized

Service Center from which you bought this machine.

2. Inspecting the magazine

1

DISCONNECT BATTERY and FUEL CELL.

2

Clean the magazine. Remove paper chips or wooden

chips which may have accumulated in the magazine.

Lubricate it with Hitachi gas finish nailer lubricant.

3. Check on mounting screws for each part

At regular intervals check every part for loose mounting

screws. Retighten any loose screws. Operating the

equipment with loose screws untightened will incur

a hazard.

4. Inspecting the push lever

Check if the push lever can slide smoothly.

Clean up the sliding area of the push lever and use the

provided oil for lubrication from time to time.

Lubrication enables smooth sliding and simultaneously

serves to prevent the formation of rust.

5. Storing (See page 9)

䡬

When not in use for an extended period, apply a thin

coat of the lubricant to the steel parts to avoid rust.

䡬

Do not store the Nailer in a cold weather environment.

Keep the tool in a warm area.

䡬

When not in use, the tool should be stored in a warm

and dry place.

Keep out of reach of children.

6. Fuse replacement of cigarette lighter connecting plug

CAUTION

For continued protection against risk of fire, replace

only with same type and ratings of fuse in cigarette

lighter connecting plug.

250V, 6A, DC

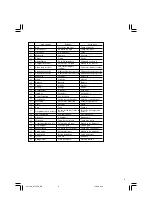

7. Service parts list

CAUTION

Repair, modification and inspection of Hitachi Power

Tools must be carried out by a Hitachi Authorized

Service Center.

This Parts List will be helpful if presented with the

tool to the Hitachi Authorized Service Center when

requesting repair or other maintenance.

In the operation and maintenance of power tools, the

safety regulations and standards prescribed in each

country must be observed.

MODIFICATIONS

Hitachi Power Tools are constantly being improved

and modified to incorporate the latest technological

advancements.

Accordingly, some parts may be changed without

prior notice.

APPLICABLE LUBRICANTS

Use HITACHI Gas Nailer lubricant.

Do not use detergent oil or additives.

These lubricants will harm the O-rings and other rubber

parts. This will cause the tool malfunction.

Noise Information

Noise characteristic values in accordance with EN 792-

13:

The typical A-weighted single-event sound power level

L

WA

,1s,d = 102.5 dB

The typical A-weighted single-event emission sound

pressure level at work station

L

pA

,1s,d = 96 dB

These values are tool-related characteristic values and

do not represent the noise development at the point of

use. Noise development at the point of use will for

example depend on the working environment, the

workpiece, the workpiece support and the number of

driving operations, etc.

Depending on the conditions at the workplace and the form

of the workpiece, individual noise attenuation measures

may need to be carried out, such as placing workpieces

on sound-damping supports, preventing workpiece

vibration by means of clamping or covering, etc.

In special cases it is necessary to wear hearing protection

equipment.

Vibration Information

The typical vibration characteristic value in accordance

with EN 792-13: 2.1 m/s

2

This values is a tool-related characteristic value and does

not represent the influence to the hand-arm-system

when using the tool. An influence to the hand-arm-system

when using the tool will for example depend on the

gripping force, the contact pressure force, the working

direction, the adjustment of energy supply, the workpiece,

the wrokpiece support.

01Eng_NT65GS_WE

12/3/08, 8:45

15

Summary of Contents for NT 65GB

Page 94: ...93 NT65GS 08Back_NT65GS_WE 12 3 08 8 49 93 ...

Page 96: ...95 NT65GB 08Back_NT65GS_WE 12 3 08 8 49 95 ...

Page 98: ...97 NT50GS 08Back_NT65GS_WE 12 3 08 8 49 97 ...

Page 100: ...99 08Back_NT65GS_WE 12 3 08 8 49 99 ...

Page 101: ...100 08Back_NT65GS_WE 12 3 08 8 49 100 ...