--- 32 ---

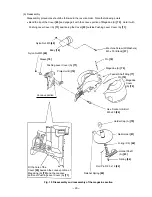

(2) Disassembly and reassembly of the adjuster unit

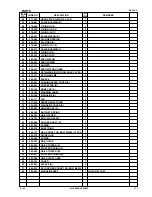

(a) Disassembly (See Fig. 23.)

Remove the Retaining Ring (E-type) for D3 Shaft [51]. Then Pushing Lever (A) [31], Pushing Lever Cover

(B) [30] and the adjuster unit can be removed.

Pull out the Roll Pin D2 x 16 [43]. Then the adjuster unit can be disassembled.

(b) Disassembly

Disassembly procedures should be followed in the reverse order. Note the following points.

Mount Adjuster Plate (A) [47] facing its bent portion toward the Adjuster [44].

Mount Adjuster Plate (B) [46] facing its convex portion toward Adjsuter Plate (A) [47].

(1) Disassembly and reassembly of Nose [22], Pushing Lever (A) [31] and other parts

(a) Disassembly (See Figs. 21 and 22.)

Remove the four Nylock High Tension Bolts M6 x 20 [23]. Then the Nose [22], Pushing Lever (A) [31] and

other parts can be removed.

(b) Reassembly

Disassembly procedures should be followed in the reverse order. Note the following points.

Apply grease to the O-ring (S-46) [13] and mount it in the groove of the Nose [22].

Align the bent portion of Adjuster Plate (A) [47] with the concave portion of the Pushing Lever Guide [40].

After reassembly, check the components of the pushing lever and the Adjuster [44] move smoothly.

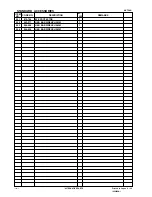

Fig. 22

Pushing Lever Guide [40]

Bent portion of Adjuster

Plate (A) [47]

Adjuster [44]

Align the positions.

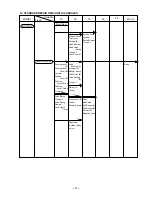

Summary of Contents for NV 75AG

Page 45: ......