-3-

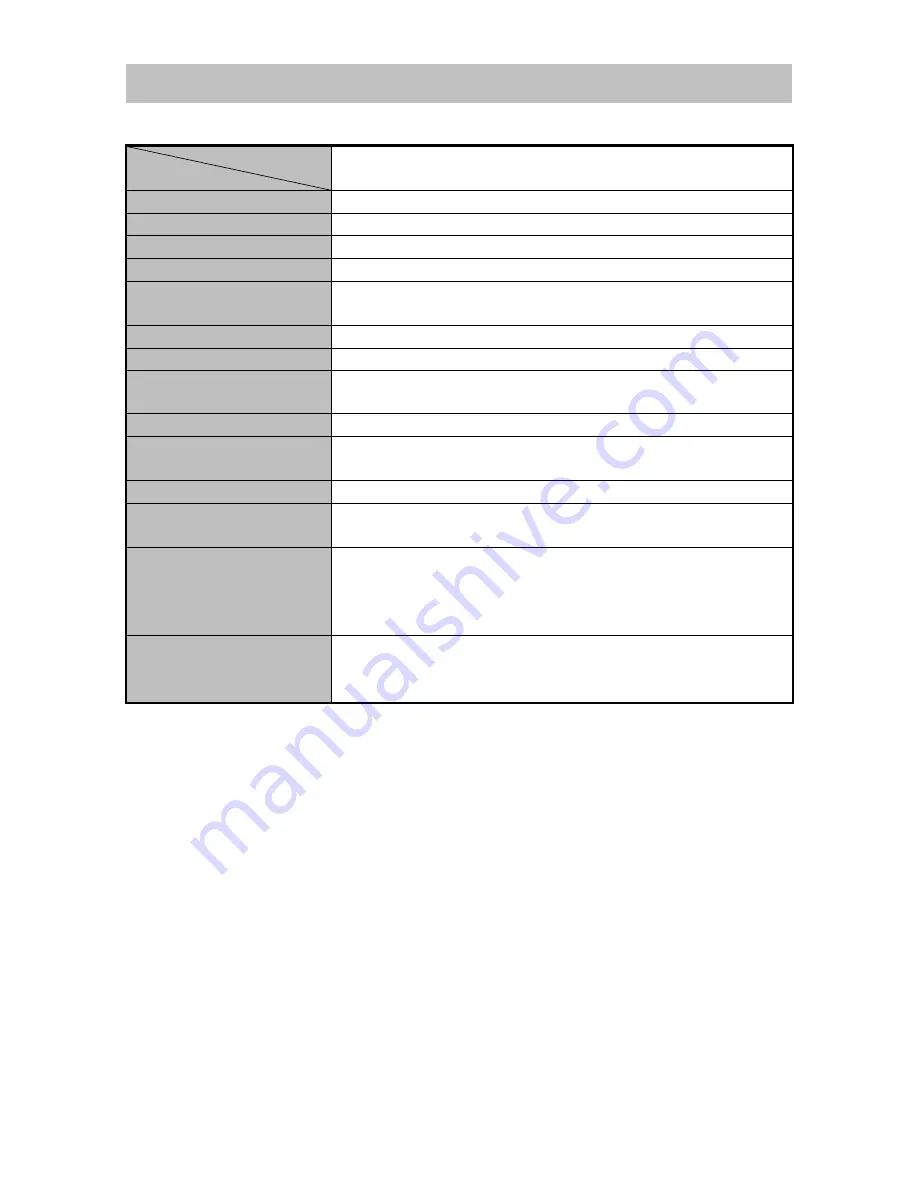

1. Specifications

Model

Item

NV 90HMC

Punching system

Reciprocating piston type

Operating pressure

12 to 23 kgf/cm

2

(170 to 320 psi, 12 to 23 bar) (Gauge pressure)

Punching speed

Min. 3 pcs./sec.

Weight

2.5 kg (5.5 lbs.)

Dimensions

(Length x Height x Width)

281 mm x 322 mm x 132 mm

(11-1/16" x 12-11/16" x 5-3/16")

Nail feed system

Reciprocating piston type

Nail capacity

150 to 300 (1 roll)

Air consumption

2.3 ltr/cycle at 20 kgf/cm

2

(.081 ft

3

/cycle at 280 psi) (2.3 ltr/cycle at 20 bar)

Air inlet

Air plug for high pressure nailer

Air hose

Air hose for high pressure nailer

(Inner diam.: 5 to 6 mm (13/64” to 15/64”))

Packaging

Corrugated cardboard box (sleeve type)

Packaging dimensions

(Length x Height x Width)

355 mm x 410 mm x 170 mm

(14" x 16" x 6-11/16")

Standard accessories

• Case (Code No. 886432)

• Eye protector (Code No. 875769)

• Oiler (30 cc) (Code No. 883136)

• Nose cap (A)(Code No. 886889)

Optional accessories

• Pneumatic tool lubricant (1 oz oil feeder) (Code No. 877153)

• Pneumatic tool lubricant (4 oz oil feeder) (Code No. 874042)

• Pneumatic tool lubricant (1) (Code No. 876212)

NOTE: The Model NV 90HMC applies higher punching force than that of conventional nailers. The

customer must therefore procure an air compressor and an air hose designed for high-

pressure nailers.

The air plug of the Model NV 90HMC is exclusively designed for high pressure and cannot be

connected to any air hoses and compressors that are generally used at much lower air

pressures. Never modify the air plug for lower pressure.

SPECIFICATIONS