English

14

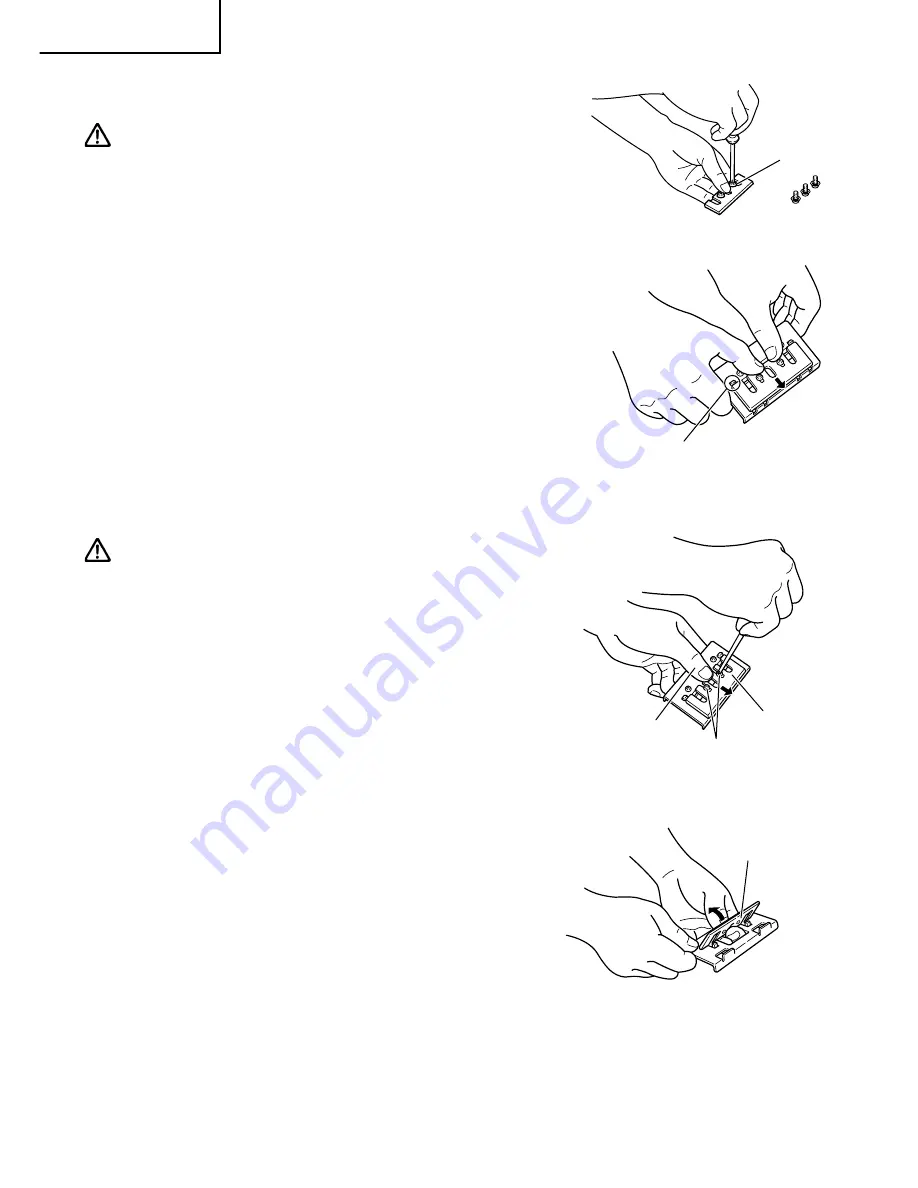

3. Adjustment of cutter blade height:

CAUTION:

●

As the set gauge has been accurately factory

adjusted, never attempt to loosen it.

(1) After attaching the back metal to the cutter

blade, temporarily fasten them together with

machine screws, as shown in Fig.13.

(2) Insert the set gauge plate spring into the hole on

the back metal and heavily push the plate spring

in the direction indicated by the arrow in Fig.14

until it snaps into the correct position.

(3) Holding the set gauge with the blade edge

facing downward as shown in Fig.15, loosen

the temporarily fastened machine screws and

lightly push the cutter blade with a thumb until

the cutter blade gently touches plate.

CAUTION:

●

Do not push the blade with excessive pressure.

Excessive pressure could cause maladjustment of

the blade height.

(4) Finally, retighten the machine screws to securely

fasten the cutter blade and the back metal,

thereby completing the blade height adjustment

procedure.

(5) Holding the set gauge as shown in Fig.16, push

upward on the back metal and remove it from

the set gauge.

(6) The cutter blade is now ready to be mounted on

the planer as described in the section on cutter

blade assembly.

Fig. 13

Fig. 14

Machine

screw

Fig. 15

Align the back metal end with

on extruded portion.

Lightly push with

a thumb.

Plate

Machine screw

Fig. 16

Push up the back

metal for beneath