English

15

SHARPENING THE CUTTER BLADES

Use of the optional accessory Blade Sharpening Ass’y

is recommended for convenience.

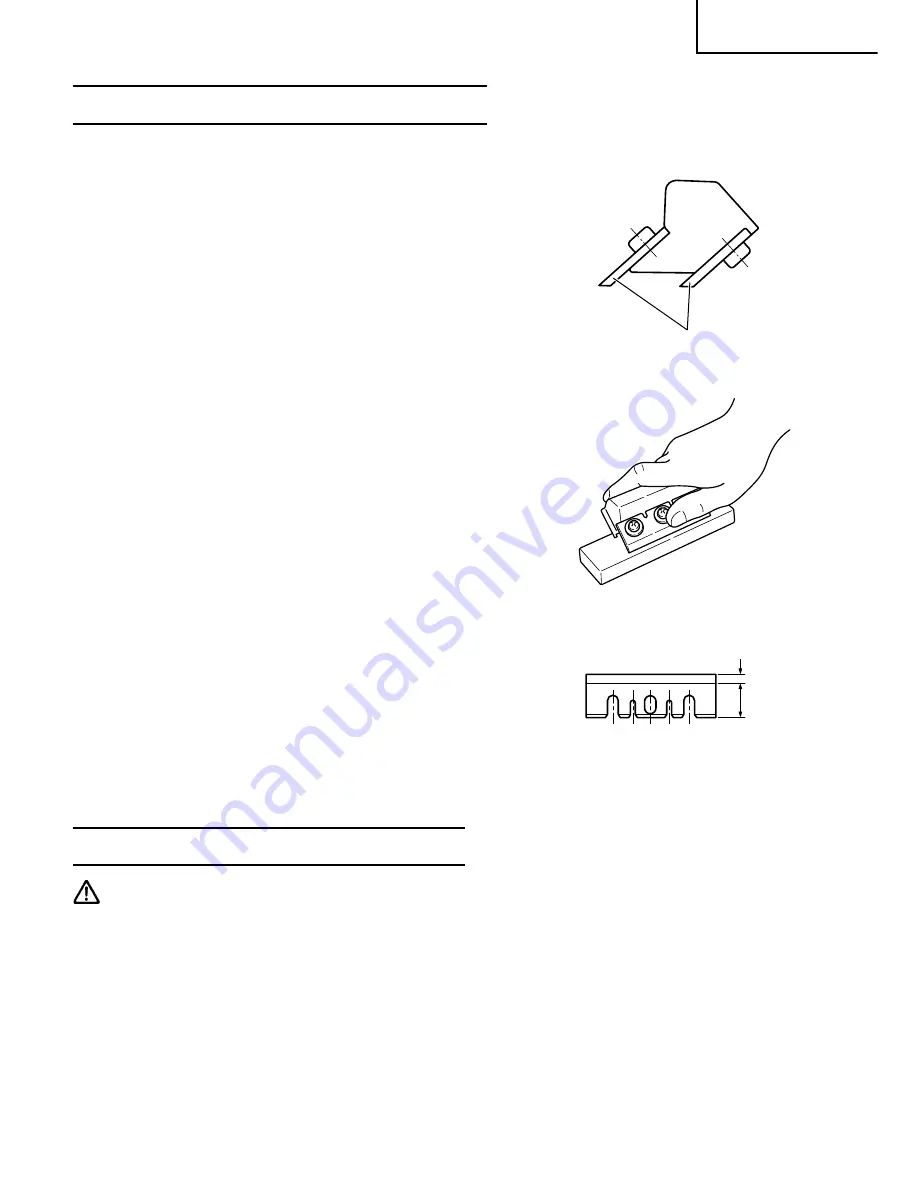

(1) Use of Blade Sharpening Ass’y.

As shown in Fig. 17, two blades can be mounted on

the blade sharpening ass’y to ensure that the blade

tips are ground at equal angles. During grinding,

adjust the position of the cutter blades so that their

edges simultaneously contact the grinding stone

as shown in Fig. 18.

(2) Cutter blade sharpening intervals:

Cutter blade sharpening intervals depend on the

type of wood being machined and the cutting

depth. However, sharpening should generally be

effected after each 1640ft (500m) of cutting

operation.

(3) Grinding allowance of the cutter blades:

As illustrated in Fig.19, a grinding allowance of

0.14" (3.5mm) is provided for on the cutter blade.

That is, the cutter blade can be repeatedly sharpened

until its total height is reduced to 0.96" (24.5mm).

(4) Grinding Stone

When a water grinding stone is available, use it

after dipping it sufficiently in water since such a

grinding stone may be worn during grinding

procedures, flatten the upper surface of the grinding

stone as frequently as possible.

MAINTENANCE AND INSPECTION

WARNING:

Be sure to switch power OFF and disconnect the plug from the receptacle

during maintenance and inspection.

1. Inspecting the cutter blades:

Continued use of dull or damaged cutter blades will result in reduced cutting efficiency

and may cause overloading of the motor. Sharpen or replace the cutter blades as often

as necessary.

Fig. 17

Fig. 18

Machine

screw

Fig. 19

Cutter blade

Grinding allowance 0.14"

(3.5mm)

0.96"

(24.5mm)