-4-

Conduct reassembly by reversing the disassembly procedure. However, special attention should be given

to the following:

• When connecting the internal wire to install the handle cover, be careful to avoid causing insufficient

withstand voltage due to the internal wire being caught between the handle cover and housing.

• Machine Screw (Black) M4 x 16

[49]

--------------------------------------- 1.8 ± 0.4 N•m (18 ± 4 kgf•cm)

• Hex. Socket Set Screw M5 x 8

[33]

----------------------------------------- 0.5 to 1.0 N•m (5 to 10 kgf•cm)

• Bolt M6

[9]

------------------------------------------------------------------------- 10.0 to 15.0 N•m (100 to 150 kgf•cm)

• Brush Cap

[37]

------------------------------------------------------------------- 1.0 ± 0.5 N•m (10 ± 5 kgf•cm)

• Pulley (A)

[50]

--------------------------------------------------------------------- 8.0 ± 1.0 N•m (80 ± 10 kgf•cm)

• Pulley (B)

[41]

--------------------------------------------------------------------- 8.0 ± 1.0 N•m (80 ± 10 kgf•cm)

• Tapping Screws D4

[21] [30] [32] [53] [69]

-------------------------------- 2.0 ± 0.5 N•m (20 ± 5 kgf•cm)

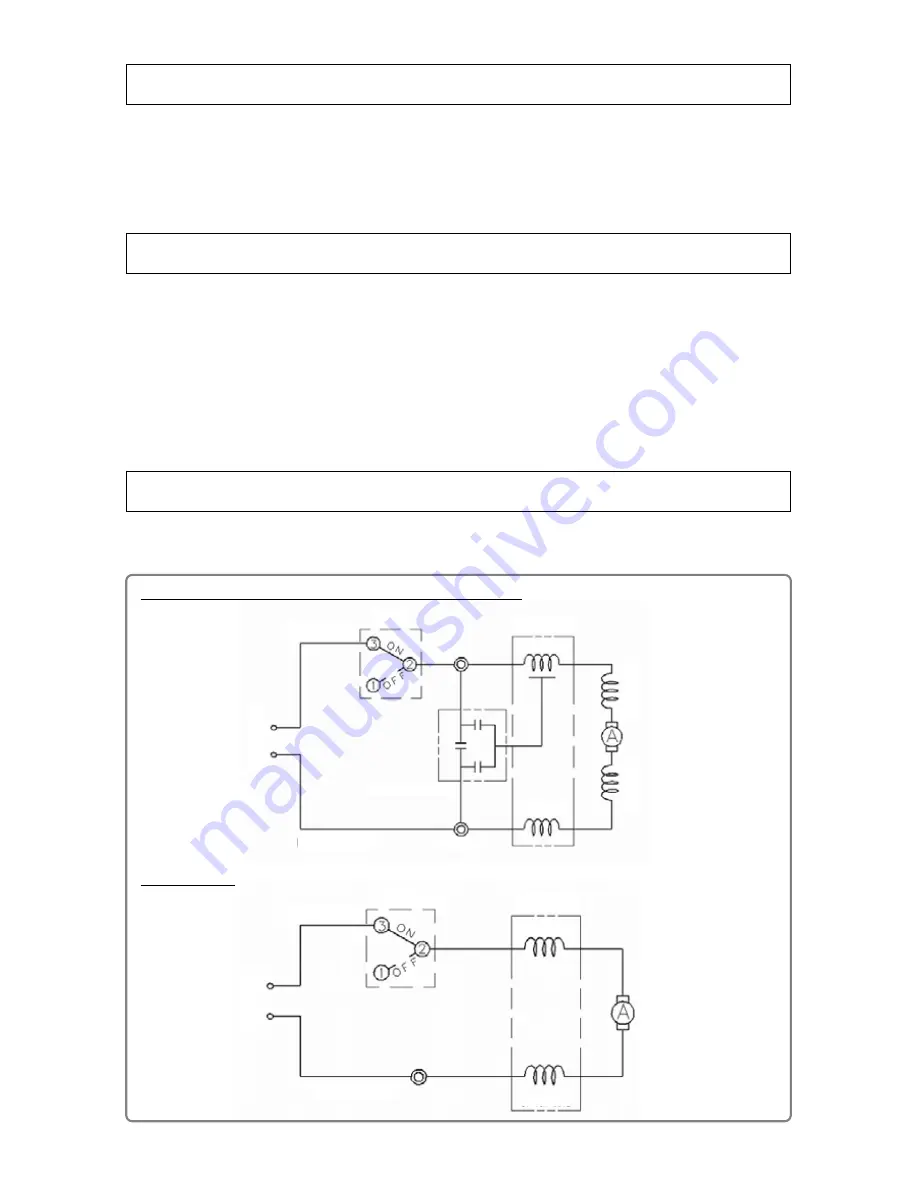

Connect the wires as illustrated in the figure below.

Be careful to avoid inoperative rotation or a short-circuit due to defective wiring.

Reassembly

Connecting diagrams

Tightening torque

For Taiwan, China, Korea, New Zealand, Australia, Europe, and South Africa

For other countries

Brown or black

Blue or white

Switch

Blue

Stator ass’y

Stator coil

Stator coil

Noise suppressor

Connector

Choke coil

Choke coil

Power supply

Brown or black

Blue or white

Switch

Stator ass’y

Stator coil

Power supply

Stator coil