h. Differences in JP-Y37 and cautions on use

The JP-Y37 ink uses organic color whose specific gravity is low for pigment.

It can be used in the same way as dye ink when periodical maintenance is

performed.

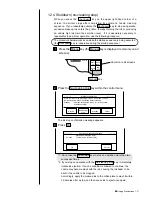

(1) Cautions during normal operation

1-6

●

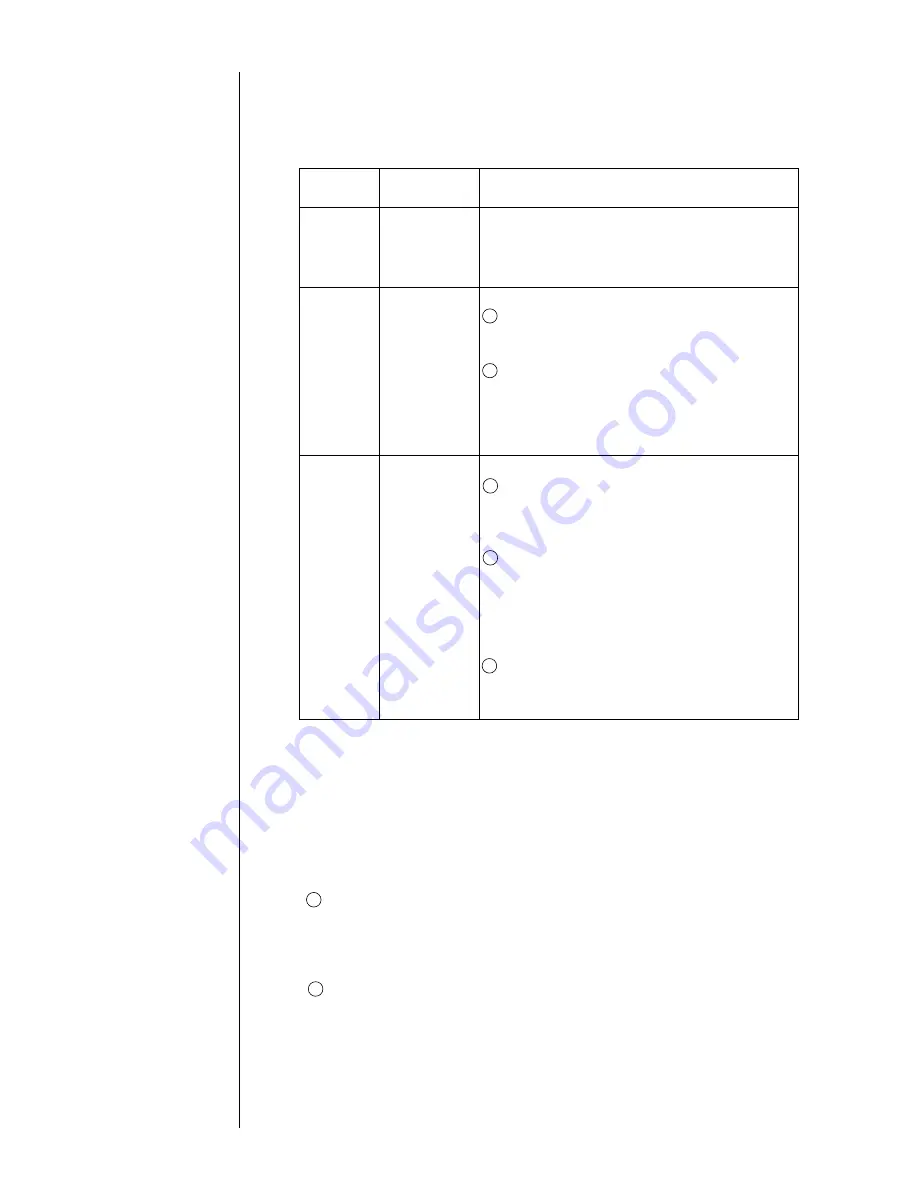

Usage Precautions

Item

Ink

Ink

reservoir

Main ink

tank

Maintenance

period

When ink is

charged,

replenished or

replaced

When ink is

replaced

(or 6 months

after ink is

charged)

When ink is

replaced

(or 6 months

after ink is

charged)

Caution during maintenance

Shake the ink bottle well until all precipitated

pigment is dispersed. (See "7.3 Ink replenishment"

and "7.5 Ink replacement".)

(See "1.3 Component names and functions")

Referring to "7.5 Ink replacement", drain the ink

from ink reservoir, and check to see if there is

any sediment at the bottom of ink reservoir.

If there is any sediment, pour the makeup ink

on the sediment in ink reservoir to wash it out.

(Also wash the inside of ink reservoir with the

makeup ink.) Drain the makeup ink after

washing, and charge new ink.

1

2

(See "1.3 Component names and functions")

Check to see if there is any sediment at the

bottom of ink reservoir. (A dark yellow

substance at the bottom of tank can be judged

as sediment.)

If sediment is found and "7.16 Draining the Ink

from the Main Ink Tank" is not possible (the

flow from drain tube cannot be confirmed),

execute the long-term shutdown process,

referring to "7.15 Long-term Shutdown", and

remove the sediment.

If the sediment cannot be removed, replace the

main ink tank. When replacing the main ink

tank, contact your local distributor.

1

2

3

(2) Caution when continuously injecting ink:

When ink is continuously injected, it even once a day for more than a month,

perform the circulation of ink without interruption at least once a month,

referring to "7. Circulation System Operating and Adjustment Procedures", in

order to prevent sediment of ink accumulating in print head cable tube.(No

printing can be performed while "Ink Circulation" is being executed.)

(3) Other cautions

If the nozzle or gutter is dried by mistake and ink is stuck to it, and it cannot

be recovered by solvent washing with makeup ink, immerse nozzle or gutter

in household detergent of approx. 0.5% and wash in an ultrasonic washer

for approx. 10 minutes. The stuck ink will be loosened and can then be

removed.

When using the printer in an environment where the humidity is more than

85%, the amount of sediment may increase. Perform air purge (see "1.2.6

Print head air purge").

1

2

Summary of Contents for PXR-D

Page 319: ...3S23L1307 3B PXR D E7 HEC ...