1-20

●

Installing Precautions

(8) If ambient humdity is 85

to

90%RH, you must purge inside of print head by air.

It is necessary for dry-clean air, refulator for pressure of air and air filter.

(Quantities of the air are 1L / minutes.)

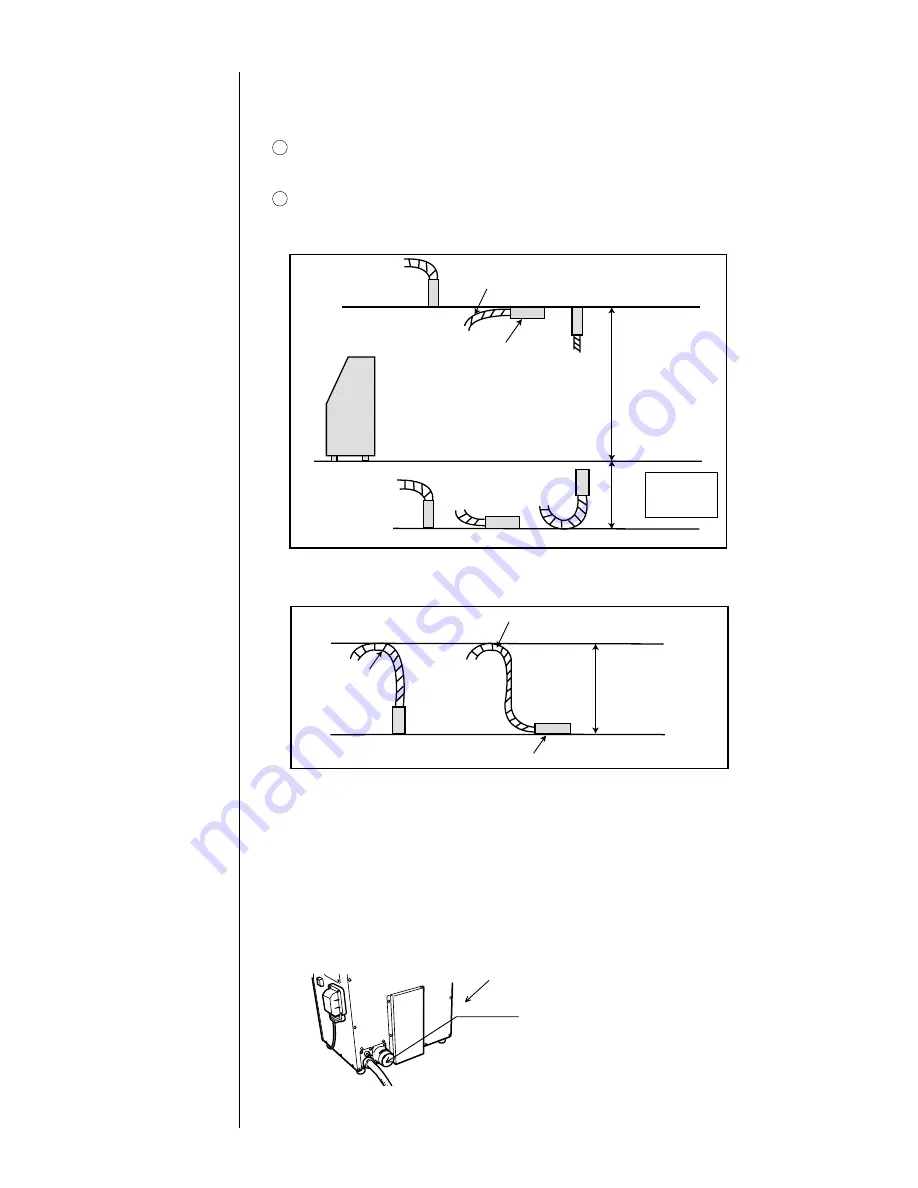

(9) When installing the print head and print head cable, comply with the following conditions.

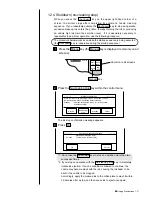

1 When positioning the end of the print head above the printer main body installation

surface,ensure that the distance between the end of the print head and the installation

surface does not exceed 1.5 m.

2 When positioning the end of the print head below the printer main body installation

surface, ensure that the distance between the end of the print head and the

installation surface does not exceed 1 m.

Upward printing Lateral printing Downward printing

Print head

cable included

1m

1.5m

Print head

Print head cable

Main body installation surface

IJ printer

main body

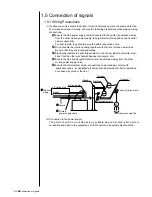

(10) When using the printer for upward or lateral printing, ensure that the rising print head

cable upper end is positioned not more than 0.5 m above the print head.

Print head

Print head cable

Bend R

0.5m

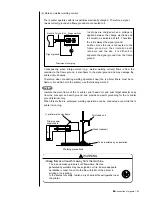

(11) If you fixed the print head, ensure that the minimum bend radius of the print head

cable is at least 150 mm.

(12) The ink stream may bend for some reason or other (due, for instance, to dirt).

The facilities positioned in the direction of ink ejection should be partially covered as

needed to avoid ink accumulation.

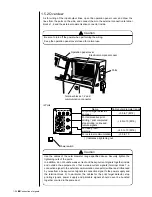

(13) When connecting an exhaust duct to the printer, install a damper and adjust the wind

velocity at the intake port to 0.3 to 0.5 m/s.

(Use an anemometer for verification. If the wind velocity is too high, the makeup ink

consumption increases.)

Exhaust duct

Connect a duct to this port

(50 mm in diameter).

Summary of Contents for PXR-D

Page 319: ...3S23L1307 3B PXR D E7 HEC ...