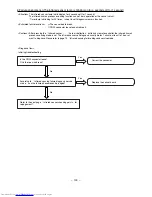

Checking the indoor unit electrical parts

Yes

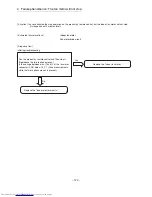

Is the "timer lamp" (orange) of the indoor unit blinking?

Introduction

Check results and next check items

Yes Yes

Yes

−

Yes

−

No

No

No

No

No

−

Check 1

Check 2

Check 3

Check 4

Move on to "Timer lamp blinking" .

(page 101 and subsequent)

Is the "monitoring lamp" (yellow) of the indoor unit

blinking?

Set the remote control unit to cooling mode, temperature setting 16

℃

(summer), heating mode, temperature setting

32

℃

(winter) and operate the product.

Check 2: Has the product received the remote control signal and has the "operation lamp" gone on? (Yes/No)

If you responded "Yes" to Check 2:

Check 3: Is the compressor of the outdoor unit running? (Yes/No)

If you responded "No" to Check 2:

Check 4: Does the "emergency operation switch" work? (Yes/No)

First check the failure phenomenon and status, and then move on to elaborate diagnosis.

Go on to "Checking the electrical parts

of the outdoor unit". (page 107)

Initiating troubleshooting

No

No

Yes

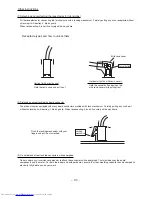

Turn off the power, wait at least 5 seconds, turn it back on, and observe the way the horizontal vanes move for about

30 seconds.

Check 1: Have the horizontal vanes moved? (Yes/No)

Go on to "The power will not become turned on".

(page 92)

Next check item

Go on to "The compressor will not run". (page 96)

Go on to "The product will not receive the remote

control signal". (page 93)

– 116 –

Summary of Contents for RAC-10SH3

Page 57: ... 55 MODEL RAC 18SH3 Unit mm 580 5 600 345 299 19 5 ...

Page 60: ... 8 5 WIRING DIAGRAM MODEL RAS 10SH3 3 H S 4 1 S A R 3 H S 8 1 S A R INDOOR UNIT ...

Page 62: ... 0 6 MODEL RAC 18SH3 OUTDOOR UNIT WHT YEL RED INDOOR UNIT ...

Page 64: ... 2 6 3 H S 8 1 S A R 3 H S 4 1 S A R 3 H S 0 1 S A R L E D O M ...

Page 150: ... 8 4 1 MODEL RAC 18SH3 ...

Page 153: ...HHAW NO 0060E RAS 10SH3 RAC 10SH3 RAS 14SH3 RAC 10SH3 RAS 18SH3 RAC 18SH3 ...