– 23 –

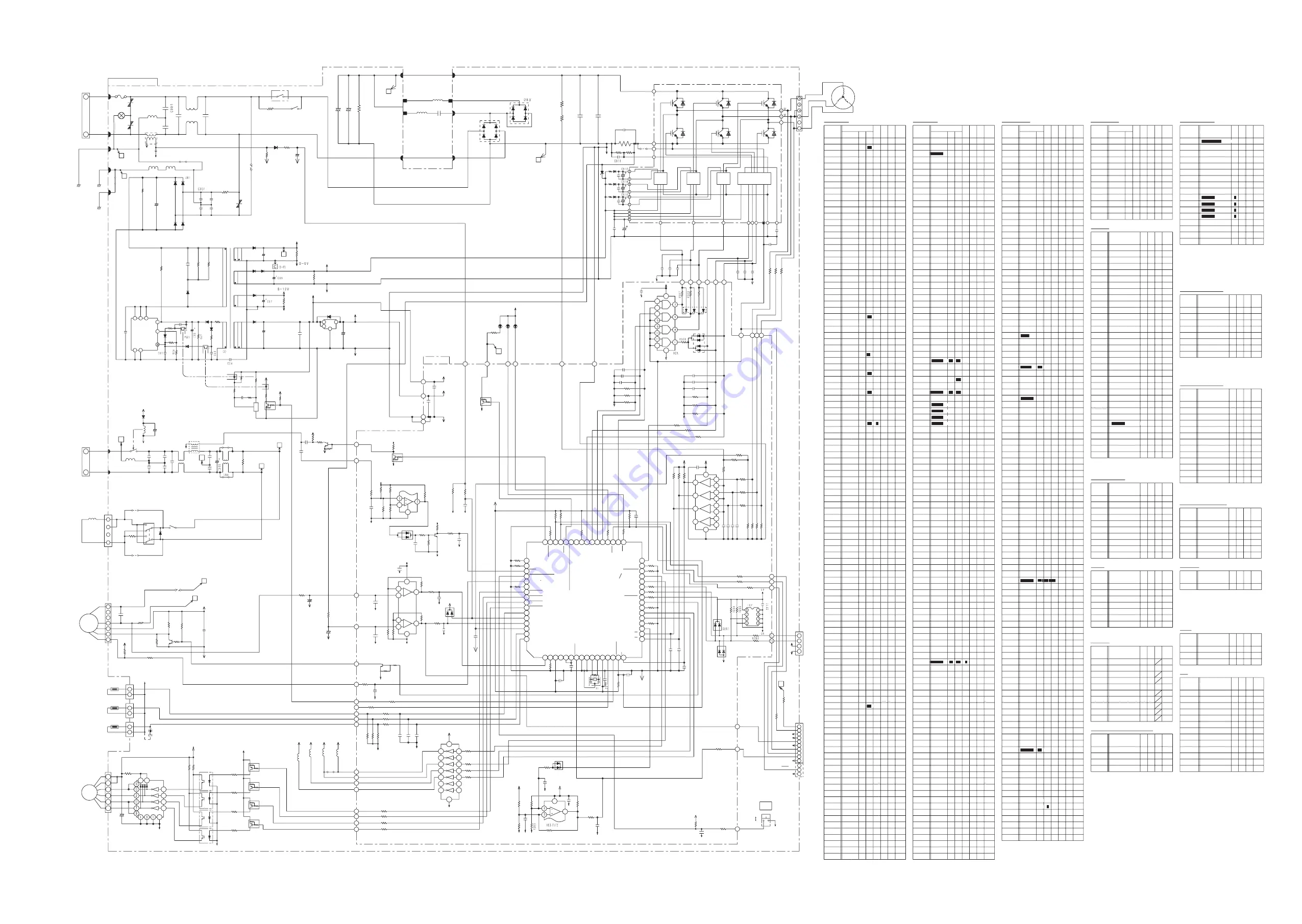

RAC-E10H2

MODEL

1

2

2K

2K

5%

A

A

A

A

1/4

5%

1/4

A

A

R401 100

100

A

5% 1/4

M

M

2K

2K

R403

R404

A

A

A

A

A

A

A

A

5%

5% 1/4

1/4

2K

2K

2K

2K

M

100

C401

R

R

R

R

100

100 25

R

R

R

R

R

R

M

M

R

R

R

R

R25

100K

100K 5% 1/4 A M

M

H

D22

JW008

124

M

H

TD62064APG

IC6

GRAY(S2)

RN2Z

CN1

PK6P(WHT)

RL4

CAPACITOR

CAPACITOR

(W)

RELATING

VALUE(Ω) LIMIT

POWER

SYMBOL

SYMBOL

RELATING

VALUE(Ω) LIMIT

POWER

(W)

VALUE(μF)

(V)

VOLT

SYMBOL

RELATING

SYMBOL

RELATING

VALUE(μF)

VOLT

(V)

SYMBOL

M

MODEL

RESISTER

M0UNTING

BOARD

PART NO.

M0UNTING

BOARD

PART NO.

RESISTER

M0UNTING

BOARD

PART NO.

TYPE

TYPE

M0UNTING

BOARD

PART NO.

M0UNTING

BOARD

PART NO.

SYMBOL

SYMBOL

M0UNTING

BOARD

PART NO.

SYMBOL

SYMBOL

M0UNTING

BOARD

PART NO.

SYMBOL

SYMBOL

M0UNTING

BOARD

PART NO.

SYMBOL

M0UNTING

BOARD

PART NO.

NSE/UNUSE

SYMBOL

MODEL

M0UNTING

BOARD

PART NO.

SYMBOL

RATING

M0UNTING

BOARD

PART NO.

SYMBOL

RATING

M0UNTING

BOARD

PART NO.

SYMBOL

MODEL

M0UNTING

BOARD

PART NO.

SYMBOL

MODEL

M0UNTING

BOARD

PART NO.

SYMBOL

R

RATING

M0UNTING

BOARD

PART NO.

SYMBOL

M0UNTING

BOARD

PART NO.

MODEL/DROWING

COMMENT

COMMENT

COMMENT

COMMENT

COMMENT

COMMENT

COMEMNT

COMMENT

COMMENT

COMMENT

COMMENT

COMMENT

COMMENT

COMMENT

COMMENT

COMMENT

TRANSISTORS

PHOTO COUPLERS

COIL・INDUCTORS

SURGE ABSORBERS

SWITCH

LED

IC

ZENER DIODE

JUMPER

RELAY

DIODES

TAB TERMINAL

8

6

11

13

9

4

4

RL5

RL4

4

4

3

3

1

1

2

2

JW004

R703

JW005

D702

WAY

VALVE

COOLING and HEATING

EXCHANGER

RELAY

WAY VALVE

RELAY

WAY

VALVE

COOLING and HEATING

EXCHANGER OF

4

4

4

CN2

VH2P

RELAY COIL(RL5)

Q401

Q402

Q403

Q404

C008

R41

C41

+

R002

3A FUSE

VS2

C013

C012

B

A

C011

R007

CT1

CT1

C003

C002

L001

RL1

RL2

0V

POWER

SA1

VS3

VS1

L101

B

A

(3−E)

(2−E)

L002

JW001

L003

GREEN1

GREEN3

0V

C010

0V

D001

+

R006

R005

C009

0V

+

8

8

8

6

6

6

1

1

1

3

2

2

2 3

3

3

10

10

7

7

+

12V

3

4

+

1

2

5V

+15V

C−35V

15−0V

D

(3−F)

C05

D22

D02

D03

R07

D04

SW−TRANS

STR−L472

R20

IC1

R25

C23

C21

D30

C10

R24

R23

R03

D24

REG1

R01

D21

D20

C04

R02

(7)

(12)

(1)

(20)

(22)

(17)

(18)

(13)

(19)

(16)

(14) (15)

(21)

0V

R46

R45

C31

D31

C32

D32

B−0V

PQ2

3

R10

5V

5V

R34

PQ1

2

2

1

Q106

C11

R13

2

3

1

1

PQ2

R11

REG2

R05

R15

TERMINAL

BOARD

BLACK

WHITE

ORANGE(S2)

15A FUSE

D33

JW013

RELAY

C023

R008

+

C022

+

C021

YELLOW

BLUE

DB2

L2

L1

L1

L1

TAB05

TAB11

L1

TAB11

L2

12V

C804

C803

L802

(2−B)

B

(2−B)

A

C

D

0V

L801

0V

RL3

R35

C

(3−D)

D

(3−D)

6,7

6,7

10

5

2

BROWN

RED

TERMINAL

BOARD

L803

+

C820

D801

45

AC

230

F H

C023

※

※

DC

1KV

C R

C100

JW012

JW011

RCR

RCR

KMX

18×35.5

IEC

IEC

IEC

APPROVAL

APPROVAL

APPROVAL

IEC

APPROVAL

IEC

APPROVAL

IEC

APPROVAL

IEC

APPROVAL

IEC

APPROVAL

IEC

APPROVAL

IEC

APPROVAL

IEC

APPROVAL

IEC

APPROVAL

ZD901

MTZJT−22B

A M 101

C806

C807

C808

C810

C809

R801

R802

R803

C801

C802

Q801

0V

5V

C219

R283

0V

+

0V

12V

12V

12V

+5V

12V

R407

R408

R409

R410

POWER RELAY COIL

(RL1)

(RL2)

ICP RELAY COIL

ICP RELAY

ICP RELAY

(3−G)

R

R004

R003

C110

W

C217

R245

+

(3−G)

Q

C100

MAIN P.W.B.

COM

VB

VCC

VCC

COM

COM

VS

HO

HO

VB

HO

VB

VS

12

12

6

6

VCC

FO

25

25

VCC

GND

23

23

2

2

2

2

2

2

24

24

24

24 7

7

18

18

22

22

21

21

26

26

Uout

VS

Wout

35

31

20

34

Vout

IPM

CIN

H

H

H

UN

VN

WN

CFO

VNO

JW010

R001

R906

R905

0V

R901

D901

R903

D903

C921

C922

C923

R902

D902

C916

C910

R615

R616

R617

C900

C901

C906

C902

C903

C904

C905

0V

0V

0V

0V

RESET

Id

φ60

RXD

TXD

0V

NMI

15V

IP

G

(6−D)

R278

0V

SW1

5V

12V

0V

R307

0V

5V

C917

ZD901

C920

SURVICE

SWITCH

NORMAL

COOLING

4

7

5

6

FM

3

1

2

1AFUSE

R107

C102

5V

R102

R101

R106

R106

Q101

R104

R103

R103

R105

C101

+15V

Q

R

(5−A)

(7−B)

15−0V

CN24

XH−7P

(WHT)

2

2

2

XA−2P

CN10

1

XA−2P

R35:1.433kΩ±2%

1

B0/70:3400K±2%

XA−2P

B0/25:3400±2%

R110:1.28kΩ±5%

B100/110:

4400K±150K

CN9

1

CN8

5V

R0:5.9kΩ±5%

TH1

OH THERMISTOR

DEF THERMISTER

OUTDOOR

THERMISTER

(WHT)

(BLK)

(RED)

1

2

4

CN17

CT−4P

3

FOR E

2

PROM

(WHT)

7

5

8

11

11

2

6

9

CN18

CT−10P

10

4

1

3

12

12

13

13

TEST PIN

LD301

LD302

R300

LD303

5V

G

(9−J)

45 44

18

17

20

19

47 46

48

43

35 34

56

57

42

U

+

54

55

53

61

63

59

60

41 40

27

26

37 36

39 38

62

32

64

29

28

31

30

RESET

V

d

W

−

V

−

IP CUT

W

+

58

V

+

23

21

33

25

51

52

49

50

8

10

6 7

12 13

9

11

24

22

3

5

1 2

16

14 15

4

SDA(EEPROM)

SCL(EEPROM)

AV

CC

X2

X1

V

CL

OSC2

OSC1

V

CC

A

B

C

U

−

NMI

OH

I

S

I

d

DEF

POWER

15/20A

IP RES

ACT ON/OFF

SDO

TXD

RXD

FM−60

°

el

°

°

V

SS

SDI

ACT PWM

φ60

DEBUG2・CHNG

TEST

P85

FAN

CURRENT

UNUSE(A/D)

MAIN POWER ON/OFF

STANDBY

OUTPUT

I/F RELAY

(NORMAL)

OPERATION RELAY

RELAY

FAN PWM

4 WAY VALVE

4 WAY VALVE)

(CONVENTIONAL

SELF

DIAGNOSIS2

DIAGNOSIS1

SELF

OUTDOOR

TEMP

AC FAN(S)

AC FAN(L)

VALVE1

VALVE2

VALVE3

VALVE4

UNUSE

MODE/

SELF

C/

SELF

MAICON(M1)

AX-8V10

FORCED COOLING

ZERO CROSS

DEBUG1・BEFORE COMPENSATIONφ60

DEBUG3・RESERVE

4 WAY VALVE ENERGIZATION

HIC

C606

R241

R220

C605

C210

C607

0V

R221

R203

R222

C206

R276

R234

R238

R239

C209

R242

R204

0V

C222

C218

R252

0V

5V

R226

C207

C204

0V

Q202

0V

R250

R281

R200

5V

0V

R201

R202

Q201

R306

0V

C304

0V

R305

R304

C303

C302

R293

R295

R298

R297

R294

R296

R301

0V

R279

R302

R280

R197

R198

R303

R290

R267

D202

C502

C503

C505

C504

C501

C506

R207

R208

R209

R206

C203

R236

R235

R240

R237

C205

R233

R199

R224

R219

R205

7

15

1

4

12

12V

10

14

9

16

6

5

8

IC2

0V

11

2

13

3

IC4

6

7

−

1

3

+

8

2

C224

0V

C223

5V

R244

D204

0V

4

R249

R246

R247

R243

12V

5

+

R248

C208

0V

−

0V

0V

0V

C228

C227

0V

0V

7

2

14

1

13

4

R502

R503

R511

R512

R501

R510

0V

0V

0V

0V

0V

0V

R509

C202

D500

R506

R504

R505

5V

D501

R256

+5V

0V

0V

C213

R255

Q205

R254

R257

C214

6

0V

5V

R261

C216

R260

R259

R262

R263

4

IC5(1/2)

D206

R258

+5V

R601

R602

R603

+

−

+

−

+12V

+

−

1

12

3

2

13

7

6

5

4

11

10

C608

R608

R609

R610

R611

C604

C603

C602

C601

R604

R605

R606

R607

+

−

14

9

8

IC3

R612

R613

D208

C225

R287

0V

C226

1

0V

12V

0V

R284

R292

0V

C215

8

5V

R286

R288

R289

0V

0V

0V

R268 Q204

5V

0V

12V

5V

C200

C201

26

23

25

25

24

28

27

46

47

45

44

31

30

20

21

22

32

33

34

35

16

15

14

13

19

36

40

37

38

39

1 2 3

12

4

5

29

4

4

4

4

4

4

43

42 4

4

4

4

4

4

41

6

7

8

9

11

10

A:Axialinsertion

R:Radialinsertion

H:Handinsertion

C:Chip surface mounting

S:In addition surface mounting

Mounting form

COMPRESOR

MORTOR

WHITE

YELLOW

RED

H:HIC

PCB SET

M:M A I N P . W . B .

R404

R403

PQ401

PQ402

PQ403

PQ404

4

3

1

2

14

C401

+

8

11

1

6

13

3

R401

6

IC6

B−0V

5

3

4

2

1

B−12V

ELCTRIC

EXPANSION

VALUE

CN15

XA−6P

(WHT)

1k

1/4

1%

R001

3%

11

47

0.025

5

H

41

26

17

39

31

5%

M

M

M

M

M

M

M

M

1/4 A

5%

A

A

A

A

1/4

47

1/4

A

A

2.2k

2%

M

7.5K

5% 1/6

2%

1/6

390

R107

2%

21

M

16

48

43

M

M

M

R105

R103

4.7K

4.7K

1/6

38

25

37

1/6

2

A

1/6

R102 3K

3K

A

A

5%

18

0.5%

0.5%

360K

1/2

R101

360K

M

A

1/2

M

R004

49

49

A M

R003

0.27

0.27

5%

M

M

M

M

A

A

1/6

1/6

M

R104

20

5%

A

10K

10K

2%

3.6K

3.6K

1/4

42

R106

H

M

A

R01

R03

A

R07

R04

R02

1/4

R007

5%

H

H

1/6

5%

H

H

100

100

1/2

R006

1.96K

240K

240K

R008

5%

A

A

A

A

1/2

1/2

1/6

R005

1K

1K

1.5M

33

A

5%

1/4

R15

R05

1% 1/4

A

R10

A

5%

A

680

5%

0.68 5

5%

R

1/4 A

390

R13

1 R

R35

6.8k 5

5%

M

M

M

M

M

45

29

10

M

34

35

R23

1%

A

A

A

A

1/6

1/6

CEMENT

10

A

H

1%

R002

R24

2.2

5%

A

A

A

A

1/6

A

A

R245 10K

10K

16

M

453

453

33

1/6

M 36

R905

M

M

M

M

M

1/6

1/6

M

M

M

M

453

453

453

453

1%

100

100

1%

M

M

1/6

R906

M

M

A

M

R901

M

1/6

14

5%

M

R902

A

A

5%

5%

1/6

R903

20

20

A

14

20

20

14

1/6

20

20

1/2

360K

R615

1/2

360K

1/2

0.5%

R617

R616

0.5%

0.5%

360K

49

49

49

A

A

A

M

M

M

39

39

A

39

39

1/4

A

3K

3K

A

5%

5%

5%

24

24

15

M

M

1/6

R803

1/4

R802

R801

M

M

R307

A

A

A

A

A

A

1/6

A

A

A

A

13

5%

A

A

R407

5

5%

M

1/6 A

M

1/6 A

12

2K 5%

R300

M 16

R283

1/6 A

5%

10K

10K

M 19

1/6

100

100

A

R278

5

5

5

5

100

100

100

100

%

C910

C02

50

10

D R

C R

50

1500p

R

R

50

C03

C

C01

C05

50

D

C10

R

2k C

C04

470p

470p

R

D

R

0.01

0.01

C803

0.01

250

AC

250

AC

250

C805

R

AC

250

R

AC

0.01

C R

DC

R

DC

250

R

R

C

C

C804

0.47

D

68

C41

H

C31

R

C

R

450

D

C06

R

0.1

C

50

25

C21

C

2k

C24

R

H

375

C021

D

D

D

D

375

375

H

R

H

C

F

C001

C002

C003

375

420

D

D

D

C022

C009

5

50 C

C007

250

250

AC

C012

420

250

0.01

0.01

C

250

H

0.47

D R

50

0.15

68 50

C802

0.022

F

F

50

0.15

C

R

C801

R

50

C806

F

F

F

F

50

50

0.15

0.15

F

C008

10

C011

R

D R

C

C010

AC

AC

88

72

72

58

72

72

67

83

58

54

54

61

62

72

72

87

61

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

M

LXZ

25

330

C11

C R M

0.1

100

0.1

5

5

81

0.01

470p

64

67

78

78

77

64

63

74

76

72

M

R

C

0.01

C809

C101

C102

5

50

M

R

0.1

5

5

67

C

50

R

R

1200p

R

R

C903

C905

C904

0.056

C906

R

F

M

M

C900

C901

69

65

69

M

M 69

R

50 F

F

50

C902

1200p

F R

1200p

50

C217

22 10 D R M 80

C219

22 10 D R M 80

A

JW010

M

Unuse

120

125

C913

C914

C915

22

22

22 35

35

35 D

D

D R

R

R M

M

M

KRE

KRE

KRE

C917

50

M

0.022

F R

62

C919

C922

C921

C923

C

C916

67

M

0.1

R

50

M

M

2SC1214CTZ

Q801

R M 117

M

Q101

R

R

115

2SC1815GR

R

R

H

TLP421

TLP421

PQ2

H

PQ1

M

M

112

112

L801

H

CT1

BEZE

BEZE

BEZE

H

L002

L001

A

A

L802

A

H

H

H M

M

M

M

M

M

M

M

155

154

152

155

153

153

153

151

RRMH3884

RRMH3884

RRMF3787

RRMF3484

H M

RRMF3797

R

R

R

R

RA−102M−C6−Y

M

M

M

149

149

149

VS2

VS1

VS3

M 147

450NR−12D

AS1

143

IC1

H

PQ05RD08

H

REG1

STR−L472

TH1

92

92

LD302

LD301

92

M

R

M

M

R

LD303

R

90

PS21564

H

IPM

M

140

JW001

Unuse

A M

RL3

RL2

RL5

RL1

H

H

H

H

M

M

M

M

137

135

137

G4A

SW1

M

H

EVQPAE07K

RL4Z

1SS120

1SS120

D30

D04

D02

A

A

DB2

D2SB60

H

A

D10XB60H

H

A

A

DB1

H

D21

D03

D24

D001

A

D20

M

M

M

M

M

M

M

M

M

M

107

95

107

107

108

105

106

106

A

AG01Z

103

D801

A

A M

M 106

M

M

M

A

A

A

1JU42

1JU42

1JU42

D903

D902

D901

1GH46

110

110

110

M

H

157

82

82

82

R703

JW004

A M

JW005

A M

M 107

A

D702

1GH46

RL4

A M

JW008

TLP421

H M 112

PQ401

112

PQ402

H M

TLP421

112

PQ403

H M

TLP421

112

PQ404

H M

TLP421

1/6 A M

R408

5

5%

390

5

5

1/6 A M

R409

5

5%

390

5

5

1/6 A M

R410

5

5%

390

5

5

390

5

5

Q401

M

M

M

M

Q402

M

M

M

M

Q403

M

M

M

M

Q404

M

M

M

M

AL01Z

3.3k

118

118

118

118

137

104

84

72

30

23

23

18

18

18

18

27

50

C920

JW011

JW012

Unuse

Unuse

A M

M

A

1W

R11

1k

1% 1/4 A M

R34

R41

1M

5%

A

A

A

A M

M

1/4

A

A

R45

220k 5

5%

A M

2

R46

220k 5

5% 2 A M

R47

470k 5

5%

A M

1/6

R20

2.2k 5

5% 1/4 A M

560

C07

330

25 D R M

330

50

C23

470

10 D R M

DC

1KV

C32

0.01

C R M

50

0.01

C013

0.01

AC

250

C R M

AC

250

C810

0.01

AC

250

C R M

C820

100

D R M

25

1GH46

1GH46

D31

EG01V1

A M

D32

AG01Z

A M

1SS120

A

A

Q106

DTC114YSA

R M

450NR−12D

450NR−12D

REG2

H

SE012

L003

A M

J/W

2mH 15A

L101

L803

L804

31

11

9

46

46

28

78

67

60

66

72

M

0.01

81

C110

72

84

DB3

D10XB60H

H M 95

99

98

99

D33

JUMPER

116

M

128

SW−TRANS

VS1

VS2

VS3

SA1

CEMENT

VR

LXZ

LXZ

LXZ

RRPJ2539

TAB05

TAB11

RRPJ2303

H M 138

BL01RN1−F

BL01RN1−F

BL01RN1−F

JW013

A M

RN2207

M

M

RN2207

M

M

RN2207

M

M

RN2207

M

M

NIKEMI

NIKEMI

NIKEMI

CEMENT

NIHON

CEMICON

NIHON

CEMICON

NIHON

CEMICON

NIHON

CEMICON

NIHON

CEMICON

Use

Use

Use

Use

SEL1120R

SEL1120R

SEL1120R

ALD112W

ALD112W

ALD112W

OUTDOOR UNIT ELECTRIC ASSEMBLY