6-2. Overload control circuit (OVL control circuit)

Overload control is to decrease the speed of the compressor and reduce the load when the load on

the air conditioner increases to an overload state, in order to protect the compressor, electronic

components and power breaker.

Overloads are judged by comparing the DC current level and set value

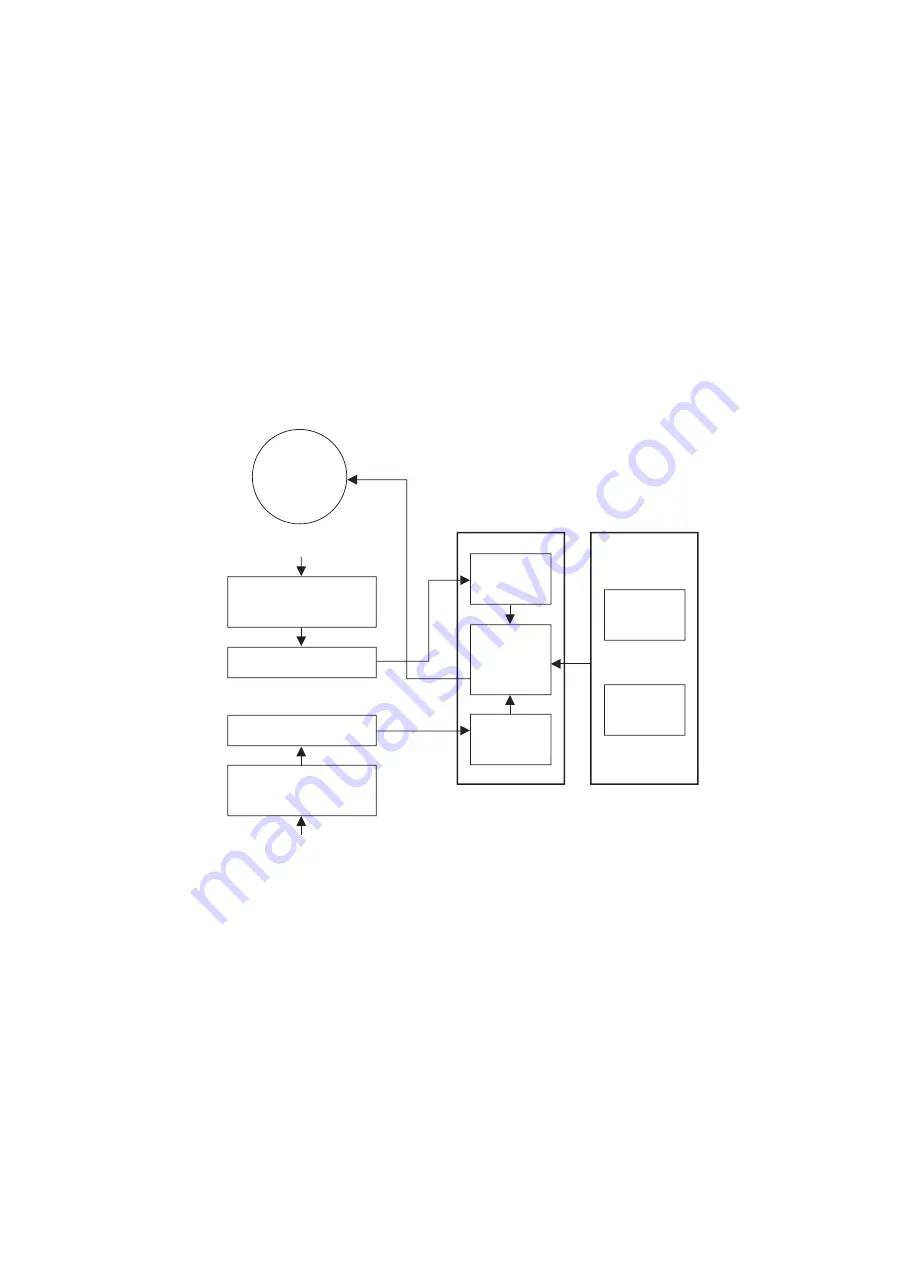

Fig.6-4 shows the overload control system configuration and Fig. 6-7 is a characteristic diagram on

overload judgement values. There are two types of control which has named IS OVL and ID OVL.

IS OVL is limiting the whole input of this room air conditioner system through the current sensor CT1

in order to keep the maximum rating of components by reading total operating current.

ID OVL is watching and limits the compressor current through the detection resistor, which is built in

IPM in order to control the compressor reliability.

reliability

reliability Since the compressor reliability is related with its

curve.

All of OVL operation values were programmed into EEPROM memory.

speed, the ID OVL value is also linked with the compressor speed. Fig.6-7 shows an ID OVL limitation

Compressor

Microcomputer

EEPROM

Motor current (ID)

Whole current (IS)

Fig. 6-4 Overload Control System

Detection

resistor

A-D

converter

ID OVL

value

IS OVL

value

Motor

control

process

A-D

converter

Detection

transformer CT1

Amplifier

Smoother

Fig. 6-5

Detection resistor

DC voltage approx.

DC 235 V

IPM (Intelligent Power Module)

DC current

Microcomputer

Fig. 6-7

Fig. 6-6

Judgment value according to rotation speed

(internal judgment value)

Rotation speed

DC current

Decelerating Accelerating

Accelerating

Actual rotation speed

Command rotation speed

Decelerating

Voltage at microcomputer pin 61

Rotation speed of compressor

- 58 -