<

IA823: C

>

FINAL

ST

AGE OF INST

ALLA

TION

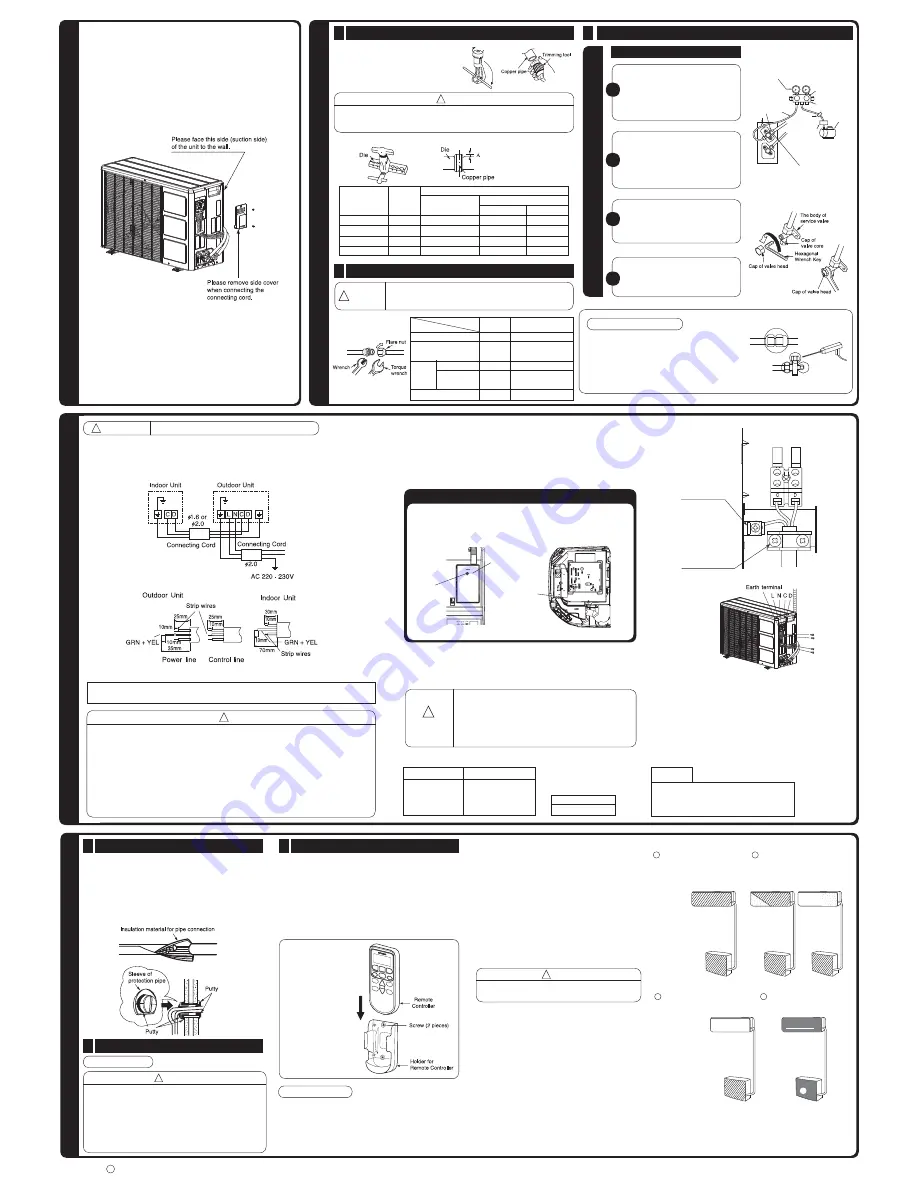

Insulation And Maintenance Of Pipe Connection

1

●

The connected terminals should be completely sealed with

heat insulator and then tied up with rubber strap.

●

Please tie the pipe and power line together with vinyl tape

as shown in the gure showing the installation of Indoor and

Outdoor units. Then x their position with holders.

●

To enchance the heat insulation and to prevent water

condensation, please cover the outdoor part of the drain hose

and pipe with insulation pipe.

●

Completely seal any gap with putty.

Installation Of Remote Controller

2

●

The remote controller can be placed in its holder which is

xed on wall or beam.

●

To operate the remote controller at its holder, please ensure

that the unit can receive signal transmitted from the controller

at the place where the holder is to be xed. The unit will beep

when signal is received from the remote controller. The signal

transmission is weaken by the uorescent light. Therefore,

during the installation of the remote control holder, please

switch on the light, even during day time, to determine the

mounting location of the holder.

Pump Down Method When Reuse

Existing Piping (R22 Model) for

R410A Model

Proper Pump Down Method

●

Compressor oil of R22 model is insoluble in compressor

oil of R410A model. The mixing of compressor oil may

cause damage of compressor.

Possibility of Mixing

●

Reuse of piping of R22 model is dangerous because

of its compressor oil.

●

When reuse piping of R22 model, pump down must be

carried out properly to ensure compressor oil which is

remained inside piping is collected away.

To Reuse Old Piping

●

Piping of R22 model can be reused only when air-

conditioner is properly pumped down.

●

The purpose of pump down is to collect back the

compressor oil (which is mixed with refrigerant and

circulating inside refrigeration cycle) properly into the

outdoor unit of air conditioner.

1

Operate air conditioner

at cooling mode for

10~15 minutes

2

After 10~15 minutes of

pre operation, close 2s

valve. After 3 minutes,

close 4s valve.

Power Source And Operation Test

3

Power Source

CAUTION

!

●

Please use a new socket. Accident may occur due to the

use of old socket because of poor contact.

●

Please plug in and then remove the plug for 2 – 3 times.

This is to ensure that the plug is completely plugged into

the socket.

●

Keep additional length for the power cord and do not

render the plug under external force as this may cause

poor contact.

●

Do not x the power cord with U-shape nail.

Operation Test

●

Please ensure that the air conditioner is in normal operating

condition during the operation test.

●

Explain to your customer the proper operation procedures

as described in the user’s manual.

The controller should

be insert from top into

bottom side of the

holder as shown in

gure beside.

OUTDOOR UNIT

●

Please mount the Outdoor unit on stable ground to prevent vibration

and increase of noise level.

●

Decide the location for piping after sorting out the different types of

pipe available.

●

Open the side plate by unscrewing the screws as shown below.

Removal Of Air From The Pipe And Gas Leakage Inspection

Gas Leakage Inspection

Please use gas leakage detector to check if leakage

occurs at the connection of Flare nut as shown on

the right.

If gas leakage occurs, further tighten the connection

to stop leakage. (Use the detector provided for

R410A)

3

Procedures of using Vacuum Pump for Air Removal

As shown in right gure, remove the cap

of valve core. Then, connect the charge

hose. Remove the cap of valve head.

Connect the vacuum pump adapter to the

vacuum pump and connect the charge

hose to the adapter.

Fully tighten the “Hi” shuttle of the

manifold valve and completely unscrew

the “Lo” shuttle. Run the vacuum pump

for about 10–15 minutes, then completely

tighten the “Lo” shuttle and switch off the

vacuum pump.

2

Completely unscrew the spindle of

the service valve (at 2 places) in anti-

clockwise direction to allow the ow of

coolant (using Hexagonal Wrench key).

3

Remove the charge hose and tighten

the cap of valve head. Check the cap’s

periphery if there is any gas leakage.

The task is then completed.

4

1

Preparation of Pipe

●

Use a pipe cutter to cut the copper pipe.

●

Jagged edge will cause leakage.

●

Point the side to be trimmed downwards during trimming to prevent copper

chips from entering the pipe.

●

Before aring, please put on the are nut.

Pipe Connection

2

INST

ALLA

TION OF REFRIGERA

TING PIPES

AND

AIR REMOV

AL

AIR REMOV

AL

●

Recommend to use

R410A aring tool.

In case of removing are nut of an Indoor unit, rst remove a nut

of small diameter side, or a seal cap of big diameter side will y

out. Prevent water from entering into the piping when working.

When the meter reaches - 101KPa

(-76cmHg) during pumping, fully

tighten the shuttle.

When pumping starts, slightly loosen the

are nut to check of air sucked in. Then

tighten the are nut.

Lo

Hi

1

Outer

dia.of pipe

6.35 (1/4")

9.52 (3/8")

12.7 (1/2")

6.35 (1/4")

9.52 (3/8")

12.7 (1/2")

Valve

head cap

Torque N·m

(kgf

·

cm)

13.7 – 18.6 (140 – 190)

34.3 – 44.1 (350 – 450)

44.1 – 53.9 (450 – 550)

19.6 – 24.5 (200 ~ 250)

19.6 – 24.5 (200 ~ 250)

29.4 – 34.3 (300 – 350)

12.3 – 15.7 (125 ~ 160)

Small dia. side

Large dia. side

Valve core cap

Small dia. side

Large dia. side

CAUTION

CAUTION

Closed

R410A

Manifold valve

Vacuum

pump

Valve

Charge hose

Valve

Vacuum pump

adapter

Meter showing pressure

!

!

Outer

Diameter (mm)

6.35 (1/4)

9.52 (3/8)

12.70 (1/2)

15.88 (5/8)

1.0~1.5

1.0~1.5

1.0~1.5

1.0~1.5

Clutch type

A (mm)

1.5~2.0

1.5~2.0

1.5~2.5

1.5~2.5

Wing nut type

Thickness

(mm)

0.8

0.8

0.8

1.0

0.0

~

0.5

0.0

~

0.5

0.0

~

0.5

0.0

~

0.5

Flare tool for R410A

Clutch type

Conventional are tool

WARNING

●

If you cannot attach the side plate due to the connecting

cord, please press the connecting cord in direction to the

front panel to x it.

●

Be sure that the hooks of the side plate is xed in certainly.

Otherwise water leakage may occur and this causes short

circuit or faults.

●

The naked part of the wire core should be 10 mm and x it to the terminal tightly. Then try to

pull the individual wire to check if the contact is tight. Improper insertion may burn the terminal.

●

Be sure to use only power cables approved from the authorities in your country. For example

in Germany: Cable type: NYM 3x1.5mm

2

, (fuse = 16A time delay)

●

Please refer to the installation manual for wire connection to the terminals of the units. The

cabling must meet the standards of electrical installation.

●

There is a AC voltage of 220-230V between the L and N terminals. Therefore, before servicing,

be sure to remove the plug from the AC outlet or switch off the main switch.

●

Do not make any connection in the middle of the connecting cable. It may cause the wire over

heated, emit smoke and re.

●

Investigate the power supply capacity and other electrical conditions

at the installation location.

Depending on the model of room air conditioner to be installed,

request the customer to make arrangements for the necessary

electrical work etc.

The electrical work includes the wiring work up the outdoor. In localities

where electrical conditions are poor, use of a voltage regulation is

recommended.

●

Install outlet for the room air conditioner within the reaching range

of the line cord.

●

THIS APPLIANCE MUST BE EARTHED.

Procedures of Wiring

Wiring of The Outdoor Unit

●

Please remove the side plate for wire connection.

!

WARNING

!

CONNECTION OF POWER CORD

WARNING

Power supply shall be connected at the rated voltage, otherwise the unit will be

broken or could not reach the speci ed capacity.

Detail of cutting the connecting cord

When removing the connecting wires for the Indoor unit, please remove the low cover panel in

front of the unit.

Fuse Capacity

16A time delay fuse

Connect the earth cord

After remove the screw

and band, put the

connecting cords and x

the band with screw.

Wiring Of The Indoor Unit

●

For wire connection of the Indoor unit, you need to open or remove front panel

and electrical cover.

Method to remove front panel

●

Please refer to Instruction Manual – “Removing the Front Panel” under “Cleaning

of Front Panel”.

Method to remove electrical cover

●

Remove the screw and electrical cover.

●

Insert the connecting cord (C, D) from the back of unit.

●

Fixed the wire to terminal wires rmly as shown in gure at right side.

IMPORTANT

Reuse of piping R-22 model only apply if previous

model is Hitachi and proper pump down method is used.

CAUTION

!

3

Take out air conditioner unit.

4

Install New Refrigerant

air conditioner

Most Important Process

Purpose: To make the

oil & refrigerant mix

together. They are in

separated condition when

air conditioner is

stopped.

Mixed

refrigerant

& oil will be

collected into

outdoor unit.

It is advisable to ush

the piping with R410A to

avoid any contamination

remain before new

installation.

Electrical cover

Connecting cord

Screw

!

Cable length

up to

1

6m

up to 15m

up to 25m

Wire cross-section

1.5mm

2

2.5mm

2

4.0mm

2

IMPORTANT

CAUTION

Outdoor supply cords shall not be lighter

than polychloroprene sheathed exible cord

with code designation 60245 IEC 57.

INS RAS-XE10CC-SX10CB (EN2) 1

7/16/13 4:11 PM