(5) Installation of indoor unit

• Set nut and washer on suspension bolt and hook it

to suspend clamp by lifting the indoor unit.

• Make sure that the indoor unit is leveled using a

level or vinyl hose with water.

• Fix the indoor unit so that the space between

bottom surfaces of ceiling and indoor unit is 58mm.

[Installation of chamber of suction grille]

[Installation of chamber of discharge grille]

[Installation of suction grille]

[Installation of discharge grille]

[Installation of flexible duct]

Refer to installation manual of optional part.

• Select the indoor unit position,

fi

xing direction of air

outlet so that cool/hot air reaches the entire room.

Standard position or the indoor unit is on wall side.

• Permissible length and bending of duct.

Permissible length

Bending

Discharging

side duct

4m or less

90° or less,

1 section

• Secure the space for installation, inspection or servicing.

• Apply waterproof treatment under the indoor unit to prevent water leak.

• Make sure that no obstacle is blocking the air

fl

ow within 1m of suction grille.

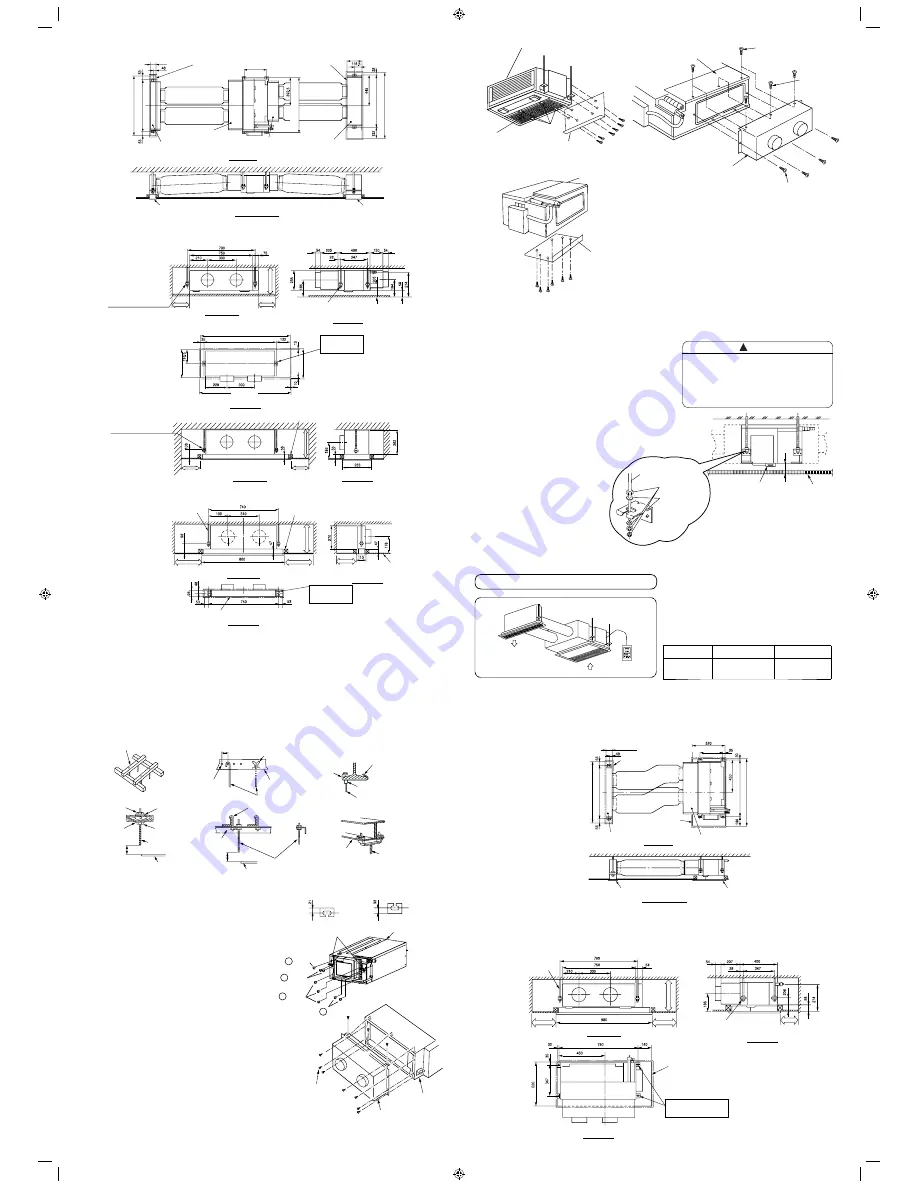

(1) Installation

fi

gure

(2) Opening on ceiling and suspension bolt position

•

Indoor unit

(1) Installation

fi

gure

(2) Opening on ceiling and suspension bolt position

• Indoor unit

•

Chamber of suction grille

•

Chamber of discharge grille

• Arrange drain pipe, refrigerant pipe, and connecting cord in their installation position.

• For

fi

nishing of opening on ceiling, arrange with builder in detail.

(3) Installation of suspension bolt

• Make sure to reinforce furring of ceiling (frame: ceiling joint and supporter) to maintain level of ceiling and

prevent vibration of ceiling plate.

• Suspension bolts should be purchased in the

fi

eld.

• Refer to diagrams shown below for length of suspension bolts.

(4) Preparation for installing indoor unit

• Remove the screw

of the electric box and then

remove electric box.

• Relocate the electric box with lead wires kept

connected. Ensure the lead wire is positioned at the

upper side, and hook the claw of electric box to the

bottom of the indoor unit using 4 screws.

• Install 4 suspension clamps at both sides of indoor unit,

2 clamps at each side, using 8 tapping screws

.

(Since size of left and right clamps are different for

certain parts, refer to diagram on the right.)

• Install chamber of discharge of unit side on the indoor

unit using 10 tapping screws.

• Remove the

fi

lter at the bottom side of indoor unit by

unscrew 8 screws at the

fi

lter holders. (4 portions)

• Remove 6 screws at back plate of indoor unit. Then

install the back plate at the bottom of indoor unit using

6 screws.

• Remove 2 screws at top plate of indoor unit and install

chamber of suction of unit side using 7 screws.

CAUTION

• Be sure to install the indoor unit level. If the

indoor unit is inclined, water may leak.

• If space between bottom surfaces of indoor

unit and ceiling is not correct, there may be a

gap between grille and ceiling surface, with

consequent leakage of condensed water.

!

•

In case of wooden frame

•

In case of steel frame

INSTALLATION OF SEMI DUCT TYPE

Opening on ceiling 96

Flexible duct

Flexible duct

Chamber of discharge grille

Cross section

Front view

Front view

Front view

Front view

Plan view

Plan view

Side view

Side view

Side view

Top view

Cross section

Plan view

Side view

Top view

Chamber of suction of unit side

Chamber of

suction grille

Chamber of discharge

of unit side

Opening on ceiling 864

Indoor unit

Suspension bolt 790

Suspension bolt 793

Opening on ceiling 960

Suspension bolt 740

Discharge opening size

(846 x 96)

Suction opening size

(960 x 233)

(Unit : mm)

(Unit : mm)

Suction grille

Discharge grille

Suspension bolt

(M10: Local purchase)

Suspension bolt

(M10: Local purchase)

Suspension bolt

(M10: Local purchase)

Reinforcement

Ceiling

Suspension bolt

(M10: Local purchase)

Above 300

Above 300

Above 300

Above 300

Opening on ceiling

60~90mm square piece of lumber

Nut

Reinforcing bar

C type metal

H beam

Nut

Ceiling

Ceiling

Suspension bolt

(M10)

Suspension bolt

(M10)

Suspension bolt (M10)

Suspension bolt (M10)

Suspension bolt (M10)

Indoor unit

Chamber of discharge

of unit side

Screw

Bend slip-preventive metal

Opening on ceiling 846

Opening on ceiling 960

Suspension bolt 790

Indoor unit

Suspension bolt 740

Angle

Angle

Angle

Hanger bolt

Concrete

Long nut

Insert

(100~150kg)

150~160mm

About 130

About 130

Above 200

Above 300

Opening on ceiling 960

Suspension bolt 793

Grille 980

Grille

253

Above 300

Reinforcement

Above 330

Above 330

Above 330

Opening on ceiling 233

Opening on ceiling 233

Indoor unit

Back plate

Back plate

Indoor unit

(1) Bottom side suction opening

(2) Back side suction opening

A level

Suspension bolt (M10)

(Local

purchase)

Hexagon nut (M10)

(Local

purchase)

Washer

(Local purchase)

58mm

Ceiling

Filter holders

Filter

Top plate

Remove the screw

Screws to fit

electric box

Chamber of suction of unit side

Screw

Suspension bolt 347

Suspension bolt

position 740

Suspension bolt

position 793

Opening on ceiling 96

Flexible duct

Flexible duct

Chamber of discharge of unit side

Suction grille

Suction opening size

(960 x 520)

Chamber of discharge grille

Above 300

Above 300

Above 200

Above 300

Discharge grille

Discharge opening size

(846 x 96)

Suspension bolt 347

Suspension bolt position

790 x 347

Suspension bolt

(M10: Local purchase)

Suspension bolt

(M10: Local purchase)

Opening on ceiling

(Unit : mm)

(Unit : mm)

Left side

suspension clamp (2)

Right side

suspension clamp (2)

Screw

3

Screw

8

Screw

3

Screw

8

INS RAD-18-25-35-50QPB (EN) 2

INS RAD-18-25-35-50QPB (EN) 2

12/19/14 9:42 AM

12/19/14 9:42 AM