3

.

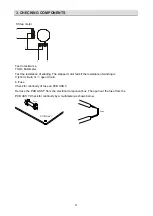

CHECKING COMPONENTS

See ----- Tube defrost.

Feel ----- The difference between tube’s temperature.

Test ----- Test pressure.

3. Checking components

3.1 Check refrigerant system

TEST SYSTEM FLOW

Conditions:

①

Compressor is running.

②

The air condition should be installed in good ventilation.

Tool: Pressure Gauge

Technique:

①

see

②

feel

③

test

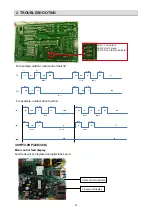

Cooling mode

Test system pressure.

Is the low pressure

normal at service

part ?

The pressure on the

high side.

The pressure on the

low side.

Recharge refrigerant

after air purging with

the vacuum

pump. Is the low

pressure normal

over again?

Air remains at the

refrigerant system.

yes

The system needs

refrigerant.The

service people must

add refrigerant. Does

the low pressure

rise ?

NO

Recharge

refrigerant.

yes

The refrigerant system is

blocked. Please check

the Capillary Tube

(

or

electronic

expansion valve).

Is it blocked?

Unsolder the capillary tube

ASS'Y(or electronic expansion

valve). The capillary tube1 is

blown by N

2

.

Check check valve and 4-

way valve.

If the pressure is

close to static

pressure?

NO

NO

4-way valve collude or

compressor exhaust very

ebb.

yes

NO

yes

3

3