10 Electrical wiring

General information

TCGB0136 rev.1 - 05/2021

98

10.1 General information

!

D A N G E R

• Do not connect or adjust any wiring or connections unless the main power switch is OFF. Check and test to ensure that if

there is more than one source of power supply, all are turned OFF.

• Use an earth leakage breaker with medium sensitivity, and an activation speed of 0.1 sec or less. If this is not fitted, there is

a risk of electric shock and/or fire.

• Install an earth leakage breaker, fuse or circuit breaker of the specific capacity for each outdoor unit power line. Not fitting

it may cause an electric shock or fire.

• Check that the earth wire is securely connected, tagged and locked in accordance with national and local codes.

• Never connect the earth cable to the refrigerant pipes. The gas in the pipes could cause a fire.

• Do not connect the earth cable to the lighting arrest system. The electrical potential of earth would increase abnormally.

!

C A U T I O N

• Before any work to the electrical wiring or regular inspections, switch off the mains power supply of the indoor and outdoor units. Wait

three minutes before starting installation or maintenance work.

• Make sure that the interior and exterior fans have come to a complete standstill before starting work on the electrical wiring or regular

inspections.

• Protect cables, the drainage pipe, electrical components, etc. from rodents and insects; otherwise these might damage unprotected

components and this could result in fire.

• Do not allow cables to come into contact with the refrigerant pipes, metal edges, printed circuit boards (PCB) or the electric components

inside the unit; the cables may be damaged and this could result in fire.

• Firmly secure the cables inside the indoor unit with plastic flanges.

• Connecting the operating line cables incorrectly may lead to faults in the PCB.

• Secure the cable of the remote control switch with the cord clamp inside the electrical box.

• Before starting work on the installation of the outdoor unit, set the DSW required to supply voltage in the correct position.

?

N O T E

• Fix the rubber bushes with adhesive when the outdoor unit ducts are not used.

• Use shielded twisted pair cable (more than 0.75 mm²) for operation wiring between outdoor unit and indoor unit, and operation wiring

between indoor unit and indoor unit. (Do not use wire with more than 3 cores).

• H-LINK twist pair shielded cable must be grounded in the outdoor unit side.

• Use shielded wires for intermediate wiring to protect the units from noise obstacle at length of less than 300 m and size complied with

local code.

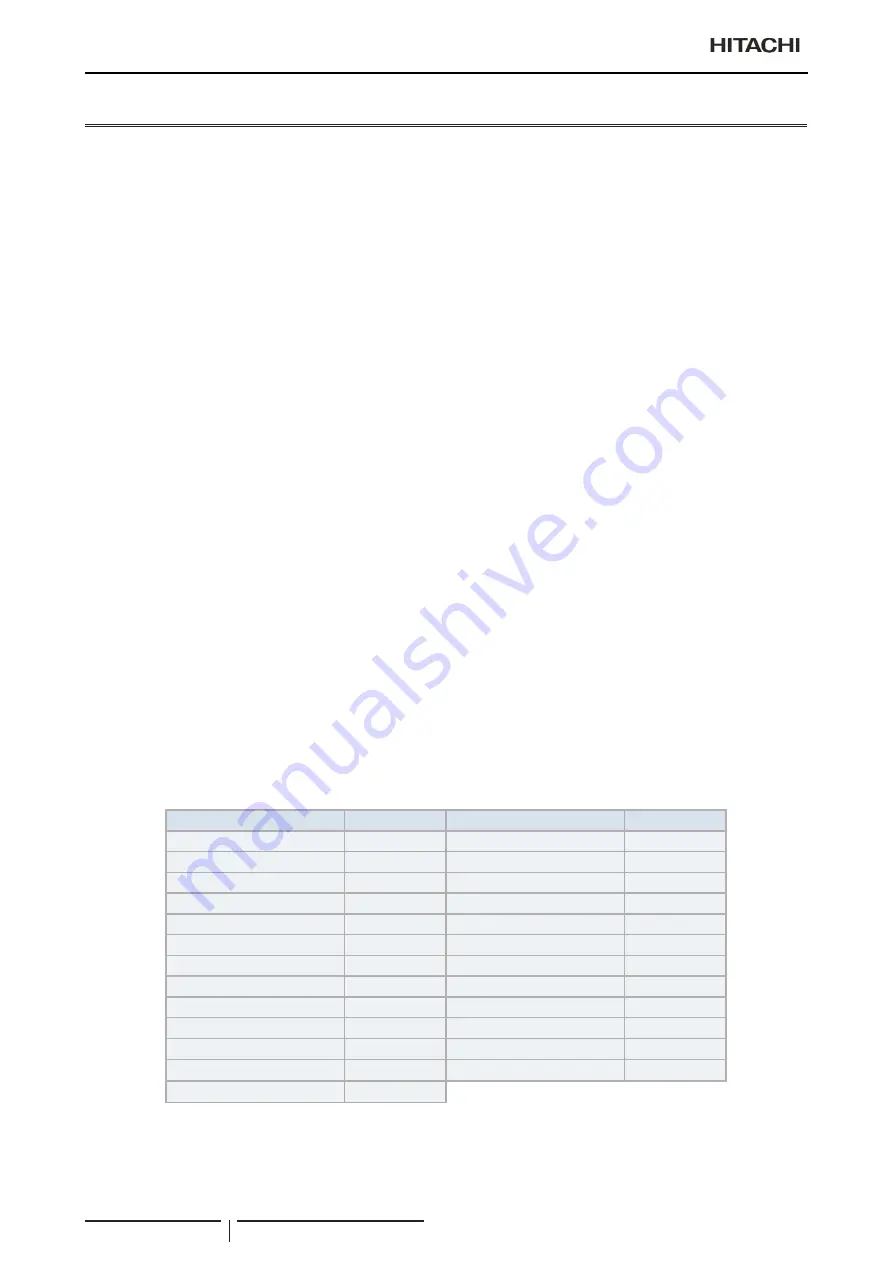

10.1.1 Electromagnetic compatibility

Following the Council Directive 2004/108/EC (89/336/EEC), relating to electromagnetic compatibility, next table indicates:

Maximum permissible system impedance Z

max

at the interface point of the user’s supply, in accordance with EN61000-3-11.

MODEL

Z

max

(Ω)

MODEL

Z

max

(Ω)

RAS-3HVRC2

0.43

RAS-4HRC2E

-

RAS-4HVRC2E

0.30

RAS-5HRC2E

-

RAS-5HVRC2E

0.30

RAS-6HRC2E

-

RAS-6HVRC2E

0.30

RAS-4HNC2E

-

RAS-4HVNC2E

0.30

RAS-5HNC2E

-

RAS-5HVNC2E

0.30

RAS-6HNC2E

-

RAS-6HVNC2E

0.30

RAS-4HRP2E

-

RAS-4HVRP2E

0.30

RAS-5HRP2E

-

RAS-5HVRP2E

0.30

RAS-6HRP2E

-

RAS-6HVRP2E

0.30

RAS-4HNP2E

-

RAS-4HVNP2E

0.30

RAS-5HNP2E

-

RAS-5HVNP2E

0.30

RAS-6HNP2E

-

RAS-6HVNP2E

0.30