29

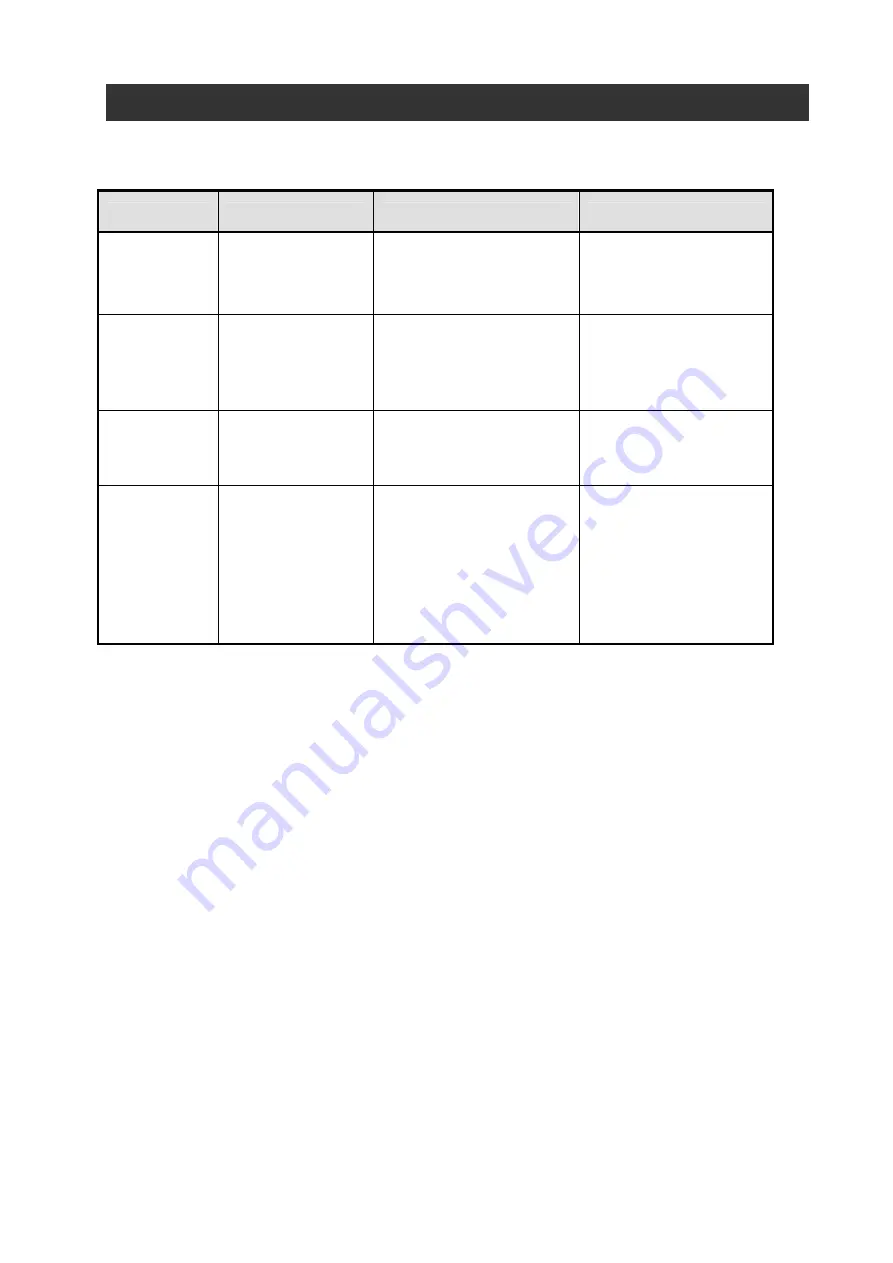

(2) WOP error message

Display

Cause

Check item

Resetting Method

EEPROM is

broken!

WOP’s EEPROM

comes to its usage

life.

Check read operation is

available or not when

inverter is power-on again.

If the copy function is

needed, please replace

the remote operator.

RTC ERROR!

Inductive noise

entries into WOP.

WOP (cable) is nearby the

inductive noise or not.

Please put WOP and its

cable far away from the

inductive noise.

Please set the right date in

option mode.

change the

battery

Battery power is

exhausted.

Whether right date displays

in parameter d031.

(Refer to Fig. 7)

Please replace it with new

battery.

please set the

clock

・

wop is used at the

first time.

・

wop is used at the

first time after

battery replaced.

・

WOP is used at

the first time after

resetting

Whether the time setting is

match to the correct time.

Please set the right date in

option mode.

Chapter 7

Error message