Water pipe

installation

Service Manual

34

General notes

SMGB0066 rev.0 - 12/2009

2.1 GEnErAl noTES

Connect all pipes as close as possible to the unit, so that disconnection can be easily performed when required.

1.

It is recommended to use flexible joints for the piping of water inlet and outlet, so vibration will not be transmited.

2.

Whenever possible, sluice valves should be installed for water piping, in order to minimise flow resistance and to

3.

maintain sufficient water flow.

Proper leak inspection should be performed to check for leaking parts inside and outside the system, by completely

4.

opening the hot water inlet and outlet valves to the water condenser. Additionally, install equip valves to the inlet and

outlet piping.

This unit is equipped with an air purge at the highest position of the water system. If this position is not the highest one

5.

within the whole water installation, equip another air purge.

Also, equip a drain cock on the outlet piping. The cock handle should be removed so that the cock can not be opened

under normal circumstances. If this cock is opened during operation, trouble will occur due to water blow-off.

When necessary, put insulation on the pipes in order to avoid heat losses.

6.

When the unit is stopped during shutdown periods and the ambient temperature is very low, it is possible that the water

7.

in the pipes and in the circulating pump freeze, thus damaging the pipes and the water pump.

In order to prevent this, during shutdown periods it is useful to empty the water from the installation.

note

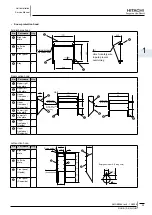

In that case, open the unit by removing the service cover and unscrew the water inlet thermistor in order to drain

-

the water of the circuit (as shown below)

Water inlet

thermistor

Otherwise, it is recommended to maintain the power supply to the installation, since an electric cord could prevent the

freezing of the water contained in the circuit.

Additionally, in cases where water drainage is difficult, an antifreeze mixture of glycol (ethylene or propylene) should be

used (content between 10 % and 40 %).

The performance of the unit working with glycol may decrease in proportion to the percentage of glycol used, since the

density of glycol is higher than that of water. (For more information, see chapter 4 of Technical Catalogue).