Water pipe

installation

Service Manual

42

Accessories hydraulic installation

SMGB0066 rev.0 - 12/2009

note

Calculate and ensure that the water volume in the system is enough (see Yutaki product manual for

-

recommendations).

Water control

caution

Malfunction. Damage by poor quality water.

-

When it is used industrial water inside hydraulic system, it rarely causes deposits of scales or other foreign

-

substances on the equipment. However, well water or river water should in most cases contain suspended

solid matter, organic matter, and scales in great quantities. Therefore, such water should be subjected to

filtration or to a softening treatment with chemicals before application as chilled water.

It is also necessary to analyse the quality of water by checking pH, electrical conductivity, ammonia ion

-

content, sulphur content, and others. Should the results of the analysis be not good, the use of industrial

water would be recommended.

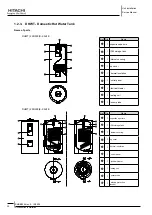

2.5.3. dHWT- domestic Hot Water Tank

Hydraulic circuit

•

When Piping connections are performed:

Connect all pipes as close as possible to the unit, so that disconnection can be easily performed when required.

1.

It is recommended to use flexible joints for the piping of water inlet and outlet, so vibration will not be transmitted.

2.

Whenever possible, sluice valves should be installed for water piping, in order to minimise flow resistance and to

3.

maintain sufficient water flow.

It is recommended to apply ball valves in both water pipe connections to make easier any maintenance work.

4.

Proper inspection should be performed to check for leaking parts inside and outside the system, by completely

5.

opening the hot water inlet and outlet valves to the water condenser.

This DHWT must be fully air purged to avoid heating elements radiating the tank case without water.

6.

Apply thermal insulation on the hydraulic system pipes in order to avoid accidental injure due to excessive heat on

7.

piping surfaces and also to avoid heat losses.

When the unit is stopped during shutdown periods and the ambient temperature is very low, it is possible that the

8.

water in the pipes and in the circulating pump freeze, thus damaging the pipes and the water pump. In order to

prevent this, during shutdown periods it is useful to empty the water from the installation.

note

Check periodically:

-

Water flow and pressure

-

Water leakage’s

-

Fixing points tightening

-

Inlet and outlet connection pipes must be 1G”

-