Electrical wiring

Service Manual

56

Accessories electrical installation

SMGB0066 rev.0 - 12/2009

note

The motor may become damaged by overvoltage.

-

Before applying voltage to the motor, double-check the voltage.

-

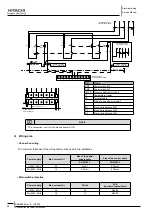

Connect to the mains and connect the SK 602/ SK 622 and SK-C2 tripping unit (observe rating plate data) in

-

accordance with the switching diagrams (Fig. 1).

ToP-S

To guarantee protection against dripping water and to ensure strain relief of the cable gland (PG 13.5), a connecting

-

cable with an external diameter of 10 - 12 mm is to be used and assembled as shown in Fig. 2. In addition, the cables

in the vicinity of the cable gland are to be bent into a run-off loop to drain off any dripping water.

Motor protection

¡

Pump

Max. power

consumption

P

1

max

(see rating plate data)

Tripping

reset

Speed switching

TOP-S 25/7

1~230V

P

1

max ≤ 245W

Internal switch off of the motor

main power supply

Auto-reset-once the motor

has cooled down the pump

will automatically switch

back on

Speed adjustment

switch, 3 settings

TOP-S 25/10

1~230V

330W ≤ P

1

max ≤ 400W

WSK and external switch

(SK602/ SK622, C-SK or other

control unit)

Manually at the external

switch box once the motor

has cooled down

Speed adjustment

switch, 3 settings

operation

¡

The system must be filled and vented properly. The pump rotor chamber will vent automatically after a short running period.

Brief dry running will not damage the pump. The pumps wich are equipped with vent screws can be ventilated as follows if

necessary.

Switch off the pump.

1.

Close the shut-off valve on the discharge side.

2.

caution

Risk of scalding.

-

Depending on the fluid temperature and the system presssure, if the vent screw is completely loosened hot

-

liquid or gas should escape or even shoot out at high pressure. Protect all electrical parts against the water

released from the unit.